Geosynthetics encompass a broad category of synthetic materials used in geological engineering to improve soil stability, control erosion, and facilitate drainage, including geotextiles, geomembranes, geogrids, and geonets. Geomembranes are a specialized type of geosynthetic specifically designed to provide impermeable barriers for containment applications such as landfill liners, water reservoirs, and mining projects. While geotextiles primarily focus on filtration and separation, geomembranes excel in preventing fluid migration, making them essential for environmental protection and containment systems.

Table of Comparison

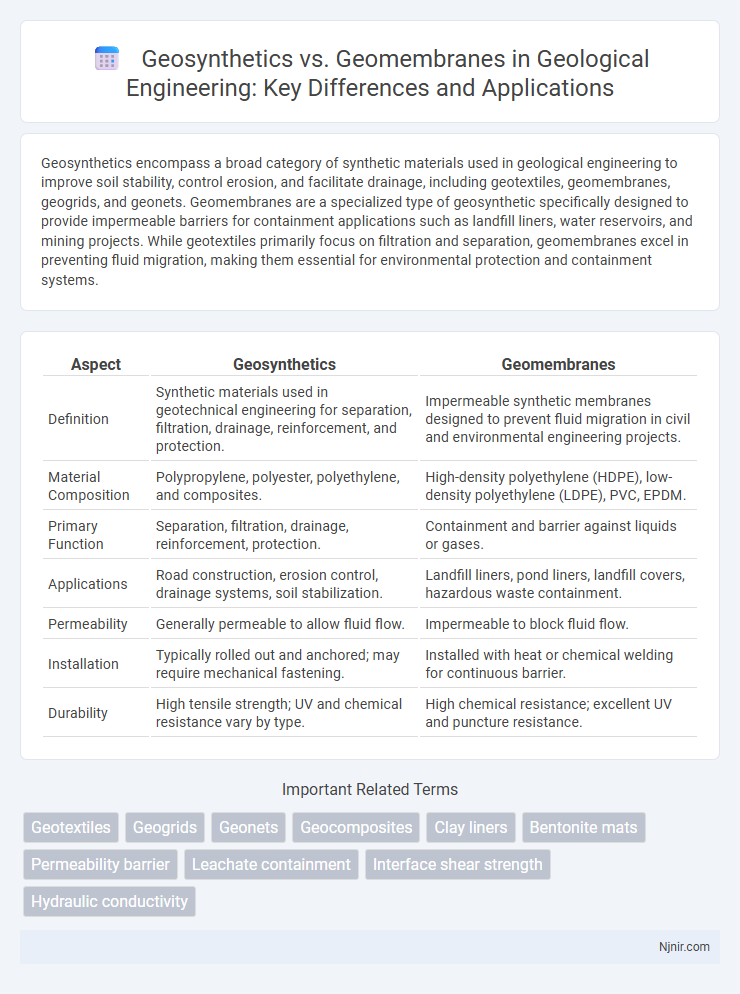

| Aspect | Geosynthetics | Geomembranes |

|---|---|---|

| Definition | Synthetic materials used in geotechnical engineering for separation, filtration, drainage, reinforcement, and protection. | Impermeable synthetic membranes designed to prevent fluid migration in civil and environmental engineering projects. |

| Material Composition | Polypropylene, polyester, polyethylene, and composites. | High-density polyethylene (HDPE), low-density polyethylene (LDPE), PVC, EPDM. |

| Primary Function | Separation, filtration, drainage, reinforcement, protection. | Containment and barrier against liquids or gases. |

| Applications | Road construction, erosion control, drainage systems, soil stabilization. | Landfill liners, pond liners, landfill covers, hazardous waste containment. |

| Permeability | Generally permeable to allow fluid flow. | Impermeable to block fluid flow. |

| Installation | Typically rolled out and anchored; may require mechanical fastening. | Installed with heat or chemical welding for continuous barrier. |

| Durability | High tensile strength; UV and chemical resistance vary by type. | High chemical resistance; excellent UV and puncture resistance. |

Introduction to Geosynthetics and Geomembranes

Geosynthetics encompass a broad category of synthetic materials used in geotechnical engineering to improve soil behavior, including geotextiles, geogrids, geomembranes, geonets, and geocomposites. Geomembranes, a subset of geosynthetics, are impermeable liners primarily used for containment and waterproofing in applications such as landfills, mining, and water reservoirs. The distinction lies in function and structure: while geosynthetics provide separation, reinforcement, filtration, and drainage, geomembranes specifically create barriers to fluid migration.

Definitions and Core Differences

Geosynthetics are synthetic materials used in civil engineering to reinforce soil, provide drainage, filtration, and separation functions, while geomembranes are a specific type of geosynthetic designed primarily for impermeable barriers to prevent fluid migration. Core differences include their primary functions: geosynthetics encompass a broad category including geotextiles, geogrids, and geonets, whereas geomembranes are focused on containment and sealing applications. Material composition varies, with geomembranes often made from high-density polyethylene (HDPE) or polyvinyl chloride (PVC) to ensure impermeability, contrasting with the diverse polymer-based materials used for other geosynthetics.

Types of Geosynthetics in Geological Engineering

Geosynthetics in geological engineering include geotextiles, geomembranes, geogrids, geonets, and geomats, each serving specific roles such as filtration, drainage, reinforcement, and containment. Geomembranes are a subset of geosynthetics, primarily used for impermeable liners and covers to prevent fluid migration in applications like landfills, reservoirs, and mining. The selection of geosynthetic types depends on project requirements, soil characteristics, and environmental conditions to ensure stability and durability in geotechnical structures.

Geomembrane Materials and Properties

Geomembrane materials primarily consist of high-density polyethylene (HDPE), low-density polyethylene (LDPE), polyvinyl chloride (PVC), and ethylene propylene diene monomer (EPDM), each offering distinct chemical resistance and flexibility characteristics. HDPE geomembranes feature superior tensile strength and chemical resistance, making them ideal for landfill liners and containment applications, while PVC offers enhanced flexibility and ease of installation in variable temperature environments. The impermeability and durability of these materials ensure effective protection against liquid migration, crucial for environmental containment and civil engineering projects.

Engineering Applications of Geosynthetics

Geosynthetics encompass a broad category of synthetic materials used in civil engineering for soil stabilization, erosion control, and drainage enhancement, while geomembranes specifically serve as impermeable barriers for containment and waterproofing applications. In engineering projects such as landfill liners, water reservoirs, and tunnel linings, geomembranes provide critical fluid containment, whereas geotextiles and geogrids contribute to reinforcement and filtration functions. The integration of geosynthetics significantly improves structural durability, reduces construction costs, and optimizes environmental protection measures.

Common Uses of Geomembranes in Construction

Geomembranes serve as impermeable barriers widely used in construction for applications such as landfill liners, pond liners, and containment systems to prevent fluid migration. These synthetic membranes are critical in environmental protection projects, including mining operations and wastewater treatment facilities, where preventing contamination is essential. Compared to broader geosynthetics, geomembranes specifically provide superior impermeability and chemical resistance, making them indispensable for sealing and isolating structures.

Performance Comparison: Durability and Longevity

Geosynthetics such as geotextiles and geomembranes differ significantly in durability, with geomembranes typically offering superior resistance to chemical degradation, UV exposure, and mechanical stress, thereby ensuring longer service life in containment applications. Geomembranes, often constructed from high-density polyethylene (HDPE) or polyvinyl chloride (PVC), can maintain impermeability and structural integrity for over 30 years under optimal conditions, whereas geotextiles primarily provide filtration and separation functions with moderate resistance to environmental factors. Performance data highlights geomembranes' enhanced longevity in landfill liners and pond liners, while geotextiles excel in soil reinforcement but may require replacement or maintenance more frequently due to lower durability metrics.

Environmental Impact and Sustainability

Geosynthetics, including geomembranes, play crucial roles in environmental protection by enhancing soil stabilization, erosion control, and waste containment, significantly reducing environmental degradation. Geomembranes specifically provide impermeable barriers that prevent leachate leakage from landfills, minimizing groundwater contamination and promoting sustainable waste management. The durability and longevity of geosynthetics reduce the need for frequent replacements, contributing to resource conservation and overall sustainability in civil and environmental engineering projects.

Installation Methods and Practical Considerations

Geosynthetics, including geotextiles, geogrids, and geomembranes, require varied installation methods tailored to their specific functions, such as unrolling, seaming, and anchoring for geomembranes to ensure impermeability and stability. Geomembrane installation demands meticulous surface preparation, precise welding techniques like extrusion or fusion welding, and rigorous quality control to prevent leaks in containment applications. Practical considerations include site conditions, environmental exposure, and compatibility with soil types, where geosynthetics offer flexibility, but geomembranes necessitate careful handling to maintain durability and performance in containment systems.

Future Trends in Geosynthetics and Geomembrane Technology

Future trends in geosynthetics and geomembrane technology emphasize advanced materials with enhanced durability, chemical resistance, and environmental sustainability. Innovations such as bio-based polymers, nanotechnology integration, and smart sensors for real-time monitoring are shaping next-generation geosynthetic products. Growing demand for infrastructure resilience and eco-friendly solutions drives research towards multifunctional geomembranes with improved mechanical and barrier properties.

Geotextiles

Geotextiles, a key type of geosynthetic material, are primarily used for filtration, separation, and reinforcement in civil engineering projects, while geomembranes serve mainly as impermeable barriers for containment and waterproofing.

Geogrids

Geogrids, a type of geosynthetic, provide superior soil reinforcement and load distribution compared to geomembranes, which primarily function as impermeable barriers in civil engineering applications.

Geonets

Geonets, a type of geosynthetic, provide superior drainage and filtration capabilities compared to geomembranes, which primarily serve as impermeable barriers in civil engineering applications.

Geocomposites

Geocomposites combine geotextiles and geomembranes to enhance soil reinforcement, drainage, and impermeability in civil engineering applications.

Clay liners

Geosynthetics, including geomembranes, offer superior impermeability and durability compared to traditional clay liners, making them more effective for preventing leachate migration in landfills and environmental containment applications.

Bentonite mats

Bentonite mats, a type of geosynthetic, provide superior hydraulic barrier performance compared to traditional geomembranes by leveraging the swelling properties of bentonite clay for self-sealing and enhanced soil stabilization.

Permeability barrier

Geomembranes provide a superior permeability barrier compared to geosynthetics due to their nearly impermeable polymeric composition, effectively preventing fluid migration in containment applications.

Leachate containment

Geomembranes provide superior leachate containment in waste management due to their low permeability and chemical resistance compared to geosynthetics, which primarily serve as reinforcement or drainage layers.

Interface shear strength

Geosynthetics typically exhibit lower interface shear strength compared to geomembranes, making geomembranes more effective for applications requiring high shear resistance at material interfaces.

Hydraulic conductivity

Geosynthetics typically exhibit higher hydraulic conductivity compared to geomembranes, which are engineered to have near-zero permeability for effective fluid containment.

geosynthetics vs geomembranes Infographic

njnir.com

njnir.com