Rock bolting provides structural reinforcement by anchoring unstable rock layers with steel bolts, effectively enhancing the stability of underground excavations. Shotcrete offers surface support by spraying a concrete mix onto exposed rock faces, forming a protective layer that prevents weathering and small-scale rock falls. Combining rock bolting with shotcrete maximizes ground control by increasing both internal rock mass cohesion and external surface protection.

Table of Comparison

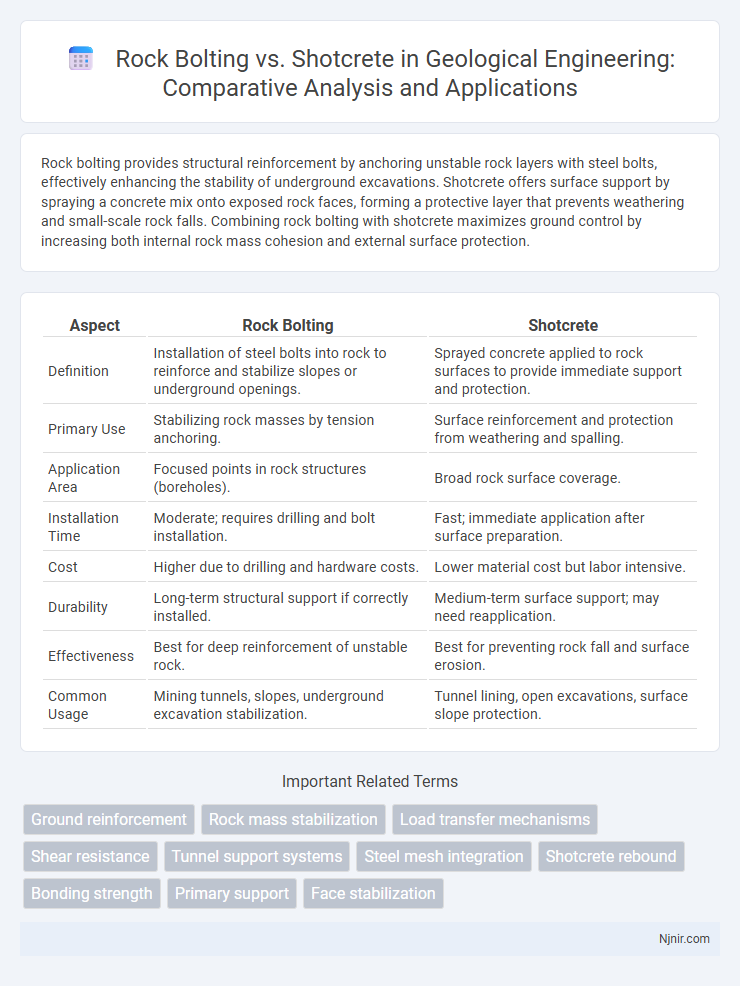

| Aspect | Rock Bolting | Shotcrete |

|---|---|---|

| Definition | Installation of steel bolts into rock to reinforce and stabilize slopes or underground openings. | Sprayed concrete applied to rock surfaces to provide immediate support and protection. |

| Primary Use | Stabilizing rock masses by tension anchoring. | Surface reinforcement and protection from weathering and spalling. |

| Application Area | Focused points in rock structures (boreholes). | Broad rock surface coverage. |

| Installation Time | Moderate; requires drilling and bolt installation. | Fast; immediate application after surface preparation. |

| Cost | Higher due to drilling and hardware costs. | Lower material cost but labor intensive. |

| Durability | Long-term structural support if correctly installed. | Medium-term surface support; may need reapplication. |

| Effectiveness | Best for deep reinforcement of unstable rock. | Best for preventing rock fall and surface erosion. |

| Common Usage | Mining tunnels, slopes, underground excavation stabilization. | Tunnel lining, open excavations, surface slope protection. |

Introduction to Rock Bolting and Shotcrete

Rock bolting stabilizes rock masses by inserting steel bolts into boreholes to enhance structural integrity, widely used in mining and tunneling for ground support. Shotcrete involves spraying concrete onto surfaces at high velocity, forming a protective layer to prevent rock falls and improve surface durability. Both methods complement each other in underground construction by providing mechanical reinforcement and surface stabilization.

Fundamental Principles of Rock Bolting

Rock bolting enhances rock mass stability by transferring load from unstable surface layers to stronger underlying strata through tensioned steel bolts, creating a reinforced composite structure. This technique relies on the mechanical interlock between the bolt, grout, and surrounding rock to effectively prevent disintegration and control deformation. Unlike shotcrete, which provides surface support and prevents loose material from falling, rock bolting fundamentally stabilizes rock by improving its intrinsic strength and cohesion.

Key Mechanisms of Shotcrete Application

Shotcrete application relies on a high-velocity spray of concrete mix, enabling rapid adhesion and superior surface bonding within rock masses, which stabilizes excavation surfaces effectively. The technique creates a consolidated, waterproof layer that reduces rock spalling and controls loose materials. Unlike rock bolting, which provides discrete point support, shotcrete distributes load evenly across the tunnel or excavation face.

Comparative Analysis: Rock Bolting vs Shotcrete

Rock bolting provides structural reinforcement by anchoring rock layers with steel bolts, offering tensile strength and flexibility in various geological conditions. Shotcrete, a sprayed concrete, adds surface support and abrasion resistance but lacks the deep anchoring capacity of rock bolts. Comparative analysis reveals rock bolting excels in stabilizing fractured rock masses, while shotcrete is more effective for surface protection and rapid application in tunnels and excavation sites.

Geological Conditions Influencing Support Selection

Rock bolting is preferred in stable geological conditions with intact rock masses, as it reinforces the rock by anchoring fractured layers, enhancing structural integrity. Shotcrete is more effective in weak, highly fractured, or weathered rock conditions, providing a continuous, flexible surface support that prevents rock fall and surface erosion. The decision between rock bolting and shotcrete depends on factors like rock quality designation (RQD), fracture spacing, and in-situ stress, which determine the rock mass behavior and support requirements.

Installation Procedures and Equipment Overview

Rock bolting installation procedures involve drilling precise holes into rock faces using rotary or percussive drills, followed by inserting steel bolts and anchoring them with resin or grout using pneumatic or hydraulic tensioning equipment. Shotcrete application requires specialized spraying equipment, such as wet-mix or dry-mix machines, to project concrete mixtures onto surfaces, ensuring rapid setting and rock stabilization. Equipment for rock bolting emphasizes drilling rigs and bolt tensioners, while shotcrete relies on compressor units, pump systems, and nozzle controls for uniform concrete distribution.

Performance and Durability in Different Rock Masses

Rock bolting offers superior performance in stable rock masses by reinforcing fractures and providing immediate support, enhancing overall structural integrity. Shotcrete excels in filling voids and binding loose rock fragments, making it highly durable in weaker, highly fractured rock masses where surface stability is critical. Combining rock bolting with shotcrete can optimize durability and long-term performance across varying geotechnical conditions in underground excavations.

Cost-Benefit Analysis: Rock Bolting vs Shotcrete

Rock bolting offers a cost-effective long-term solution by providing strong structural support with lower maintenance compared to shotcrete, which has higher upfront costs but delivers rapid surface stabilization ideal for short-term or emergency applications. Shotcrete incurs additional expenses related to materials and labor but can reduce downtime through faster application, making it beneficial in time-sensitive projects despite its relatively higher initial investment. Evaluating project scale, duration, and specific ground conditions is essential for maximizing the cost-benefit ratio between rock bolting and shotcrete in underground construction and mining environments.

Safety Considerations and Risk Mitigation

Rock bolting enhances structural stability by reinforcing rock masses, significantly reducing the risk of rock falls and collapses in underground excavations. Shotcrete provides immediate surface support, preventing loose debris from detaching and improving worker safety in unstable or fractured rock zones. Combining rock bolting with shotcrete optimizes hazard control, minimizing accidents and ensuring safer mining or tunneling environments.

Case Studies: Practical Applications in Tunneling and Mining

Case studies in tunneling and mining reveal rock bolting enhances ground stability by providing immediate support and reinforcing fractured rock masses, especially in deep underground excavations. Shotcrete application demonstrates effective surface sealing and secondary support, significantly reducing rock falls and weathering effects in tunnel linings and mine shafts. Combining rock bolting with shotcrete offers a synergistic approach, improving safety and durability in complex geological conditions.

Ground reinforcement

Rock bolting provides targeted ground reinforcement by anchoring unstable rock layers, while shotcrete offers surface stabilization through a protective sprayed concrete layer.

Rock mass stabilization

Rock bolting provides targeted reinforcement by mechanically anchoring unstable rock masses, offering superior long-term stabilization compared to shotcrete, which primarily serves as a surface support to prevent minor rock falls.

Load transfer mechanisms

Rock bolting transfers load through bond and friction within rock fractures, whereas shotcrete distributes load by providing a supportive, continuous surface layer that enhances rock mass cohesion.

Shear resistance

Rock bolting provides superior shear resistance in underground excavations by reinforcing rock masses through anchorage, whereas shotcrete offers primarily surface protection with limited shear strength enhancement.

Tunnel support systems

Rock bolting provides structural reinforcement by anchoring rock layers in tunnel support systems, while shotcrete offers a protective concrete layer that stabilizes exposed rock surfaces and prevents erosion.

Steel mesh integration

Rock bolting combined with steel mesh provides superior structural reinforcement compared to shotcrete alone by enhancing load distribution and preventing surface spalling in tunnel and underground excavations.

Shotcrete rebound

Shotcrete rebound, typically ranging from 5% to 30%, reduces material efficiency compared to rock bolting, which provides immediate and consistent ground support without material waste.

Bonding strength

Rock bolting provides higher bonding strength by directly anchoring into rock mass, while shotcrete offers surface adhesion with comparatively lower bonding strength.

Primary support

Rock bolting offers tensile reinforcement for primary support by stabilizing rock masses, while shotcrete provides immediate compressive strength by creating a protective concrete layer on tunnel surfaces.

Face stabilization

Rock bolting provides targeted tensile reinforcement for face stabilization, while shotcrete offers surface sealing and compressive support, making a combined approach optimal for controlling face deformation in underground excavations.

rock bolting vs shotcrete Infographic

njnir.com

njnir.com