Geosynthetic clay liners (GCLs) offer superior hydraulic performance and ease of installation compared to compacted clay liners (CCLs), significantly reducing permeability and enhancing barrier effectiveness in waste containment applications. GCLs are prefabricated, minimizing field variability and allowing for quicker deployment, while CCLs require careful moisture control and compaction to achieve the desired low permeability. The choice between GCLs and CCLs depends on site conditions, cost considerations, and long-term durability requirements, with GCLs often providing a more consistent and reliable solution in challenging environments.

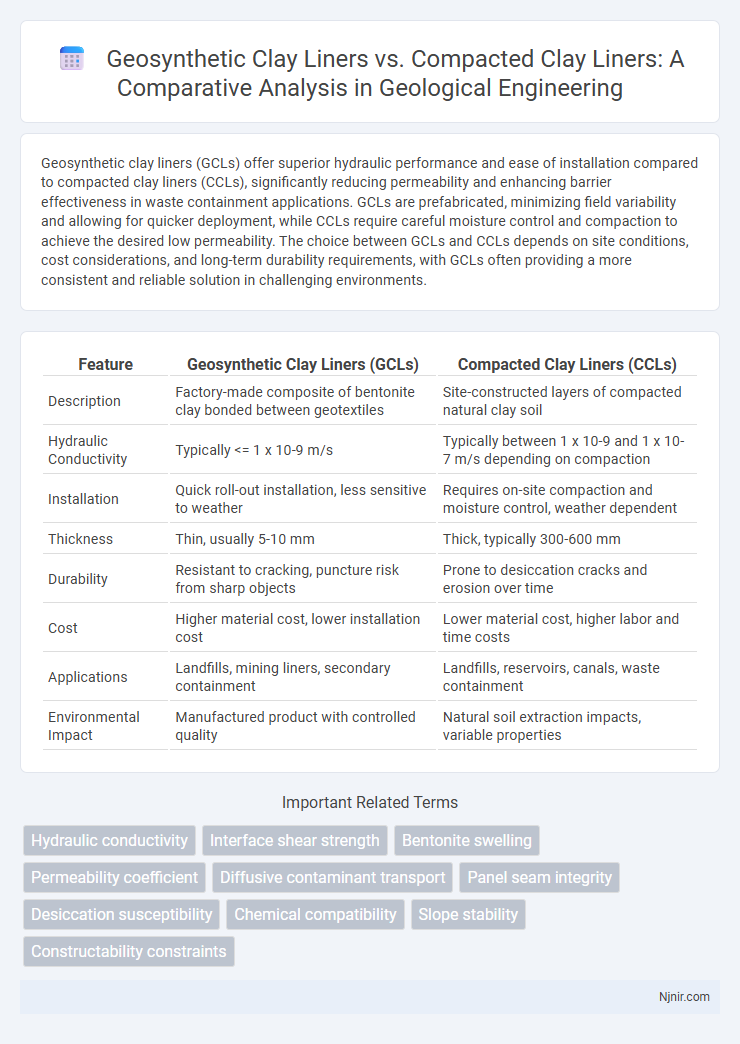

Table of Comparison

| Feature | Geosynthetic Clay Liners (GCLs) | Compacted Clay Liners (CCLs) |

|---|---|---|

| Description | Factory-made composite of bentonite clay bonded between geotextiles | Site-constructed layers of compacted natural clay soil |

| Hydraulic Conductivity | Typically <= 1 x 10-9 m/s | Typically between 1 x 10-9 and 1 x 10-7 m/s depending on compaction |

| Installation | Quick roll-out installation, less sensitive to weather | Requires on-site compaction and moisture control, weather dependent |

| Thickness | Thin, usually 5-10 mm | Thick, typically 300-600 mm |

| Durability | Resistant to cracking, puncture risk from sharp objects | Prone to desiccation cracks and erosion over time |

| Cost | Higher material cost, lower installation cost | Lower material cost, higher labor and time costs |

| Applications | Landfills, mining liners, secondary containment | Landfills, reservoirs, canals, waste containment |

| Environmental Impact | Manufactured product with controlled quality | Natural soil extraction impacts, variable properties |

Introduction to Geosynthetic Clay Liners (GCLs) and Compacted Clay Liners (CCLs)

Geosynthetic Clay Liners (GCLs) are factory-manufactured composite materials combining bentonite clay and geotextiles, designed to provide low hydraulic conductivity for effective containment in environmental and civil engineering projects. Compacted Clay Liners (CCLs) are onsite-constructed barriers formed by compacting natural clay to create a dense, impermeable layer that limits fluid migration. GCLs offer consistent quality and rapid installation, while CCLs depend heavily on site-specific soil properties and compaction methods for performance.

Material Composition and Structure

Geosynthetic clay liners (GCLs) consist of a thin layer of sodium bentonite clay sandwiched between geotextiles or bonded to geomembranes, providing a flexible and low-permeability barrier with uniform thickness. Compacted clay liners (CCLs) are made from natural clay materials mechanically compacted in situ to achieve minimal permeability and structural stability, but their effectiveness depends on the clay's native properties and adequate moisture content. The layered, factory-controlled composition of GCLs ensures more consistent hydraulic performance compared to the variable heterogeneity and potential cracking risks in compacted clay liners.

Hydraulic Performance and Permeability

Geosynthetic clay liners (GCLs) exhibit superior hydraulic performance compared to compacted clay liners (CCLs) due to their lower permeability rates, often in the range of 10^-11 to 10^-9 m/s. GCLs consist of bentonite clay layers bonded between geotextiles, providing consistent hydraulic barriers that reduce seepage effectively in landfill and containment applications. Compacted clay liners require meticulous installation and adequate moisture content to achieve permeability typically between 10^-9 to 10^-7 m/s, often resulting in variable performance and higher susceptibility to desiccation and cracking.

Installation Methods and Construction Practices

Geosynthetic clay liners (GCLs) are installed by unrolling and seaming factory-fabricated rolls over prepared subgrades, requiring minimal moisture conditioning and quick deployment, which reduces labor and time compared to compacted clay liners (CCLs). Compacted clay liners demand extensive excavation, moisture control, and mechanical compaction in thin layers to achieve low permeability, making the process labor-intensive and heavily dependent on weather and site conditions. Proper surface preparation and quality control are critical for both methods to ensure hydraulic performance, but GCLs offer more consistent installation with less variability due to their prefabricated nature.

Durability and Long-Term Performance

Geosynthetic clay liners (GCLs) exhibit superior durability compared to compacted clay liners (CCLs) due to their enhanced resistance to desiccation, chemical attack, and freeze-thaw cycles. GCLs maintain consistent hydraulic conductivity over time, ensuring reliable long-term performance in containment applications. Compacted clay liners are more susceptible to cracking and permeability increases, which can compromise their effectiveness in long-term environmental protection.

Cost Analysis and Economic Considerations

Geosynthetic clay liners (GCLs) typically offer lower installation costs compared to compacted clay liners (CCLs) due to reduced labor and equipment needs, despite higher initial material expenses. GCLs provide faster deployment and consistent quality, minimizing time-related expenses and potential errors that can increase costs with CCLs. Long-term economic considerations also favor GCLs by reducing maintenance requirements and enhancing containment efficiency, leading to cost savings over the liner's operational lifespan.

Environmental Impact and Sustainability

Geosynthetic clay liners (GCLs) offer superior environmental protection by reducing permeability and minimizing leachate migration compared to compacted clay liners (CCLs), which can be prone to cracking and differential settlement. GCLs require less raw material extraction and onsite preparation, leading to lower carbon emissions and a smaller ecological footprint during installation. Sustainability metrics favor GCLs due to their enhanced durability, reduced need for maintenance, and improved long-term containment performance in landfill and waste management applications.

Applications in Waste Containment and Landfills

Geosynthetic clay liners (GCLs) offer superior hydraulic performance and ease of installation compared to compacted clay liners (CCLs), making them ideal for waste containment and landfill applications requiring effective leachate control. GCLs consist of a layer of bentonite clay sandwiched between geotextiles, providing low permeability and self-healing properties that enhance long-term environmental protection. Compacted clay liners, while effective in traditional landfill barriers, require significant thickness and quality control during installation to achieve comparable containment, often resulting in higher labor and material costs.

Regulatory Standards and Compliance

Geosynthetic clay liners (GCLs) and compacted clay liners (CCLs) each face specific regulatory standards focused on permeability, durability, and environmental protection. GCLs often comply with strict EPA and ASTM standards, such as ASTM D5887 for hydraulic conductivity and EPA 40 CFR Part 258 for landfill liner systems, offering consistent, high-performance barriers with lower permeability rates compared to CCLs. Regulatory compliance for CCLs involves rigorous compaction and moisture content criteria to meet state and federal mandates, but variability in field conditions can challenge achieving uniform in-situ hydraulic conductivity below 1x10^-7 cm/s, influencing liner selection in waste containment and environmental remediation projects.

Future Trends and Innovations in Clay Liner Technologies

Geosynthetic clay liners (GCLs) continue to evolve with advancements in composite materials and improved hydration efficiency, enhancing their permeability and durability compared to traditional compacted clay liners (CCLs). Innovations in polymer encapsulation and nanotechnology integration are pushing the boundaries of GCL performance, enabling better resistance to chemical attacks and mechanical stresses. Future trends indicate a growing preference for hybrid liner systems combining GCLs with CCLs to optimize environmental containment and reduce installation costs in landfill and containment applications.

Hydraulic conductivity

Geosynthetic clay liners exhibit significantly lower hydraulic conductivity, typically around 10^-9 to 10^-11 m/s, compared to compacted clay liners which range from 10^-7 to 10^-9 m/s, making GCLs more effective for fluid containment in landfill and environmental applications.

Interface shear strength

Geosynthetic clay liners exhibit significantly higher interface shear strength compared to compacted clay liners, enhancing stability in landfill liner systems.

Bentonite swelling

Geosynthetic clay liners exhibit superior Bentonite swelling capacity compared to compacted clay liners, enhancing their hydraulic barrier performance in geotechnical applications.

Permeability coefficient

Geosynthetic clay liners typically exhibit a permeability coefficient around 1x10^-9 cm/sec, significantly lower than the 1x10^-7 to 1x10^-9 cm/sec range for compacted clay liners, making GCLs more effective for preventing liquid migration in containment applications.

Diffusive contaminant transport

Geosynthetic clay liners exhibit significantly lower diffusive contaminant transport rates compared to compacted clay liners due to their enhanced impermeability and uniform bentonite layer.

Panel seam integrity

Geosynthetic clay liners maintain superior panel seam integrity through durable synthetic materials and factory-controlled seams, reducing leak risks compared to the more vulnerable, field-constructed seams of compacted clay liners.

Desiccation susceptibility

Geosynthetic clay liners exhibit significantly lower desiccation susceptibility compared to compacted clay liners due to their polymeric components and enhanced moisture retention properties.

Chemical compatibility

Geosynthetic clay liners exhibit superior chemical compatibility compared to compacted clay liners due to their enhanced resistance to leachate permeation, chemical degradation, and contaminant migration.

Slope stability

Geosynthetic clay liners provide superior slope stability compared to compacted clay liners due to their lower permeability, higher shear strength, and enhanced resistance to cracking and erosion.

Constructability constraints

Geosynthetic clay liners offer superior constructability by enabling faster installation and requiring less site preparation compared to compacted clay liners, which demand extensive moisture control and compaction effort to achieve optimal hydraulic performance.

Geosynthetic clay liners vs Compacted clay liners Infographic

njnir.com

njnir.com