Tailings dams are engineered structures designed specifically for the storage of mining waste, incorporating adaptive designs to manage the unique geotechnical challenges posed by fine-grained tailings materials. Unlike traditional dams, which primarily retain water and rely on well-compacted earth or concrete, tailings dams require continuous monitoring and incremental raising to ensure stability over their operational lifespan. Advanced geotechnical analysis and consolidation techniques are critical in tailings dam construction to prevent seepage and catastrophic failure, emphasizing the importance of specialized engineering approaches in mining environments.

Table of Comparison

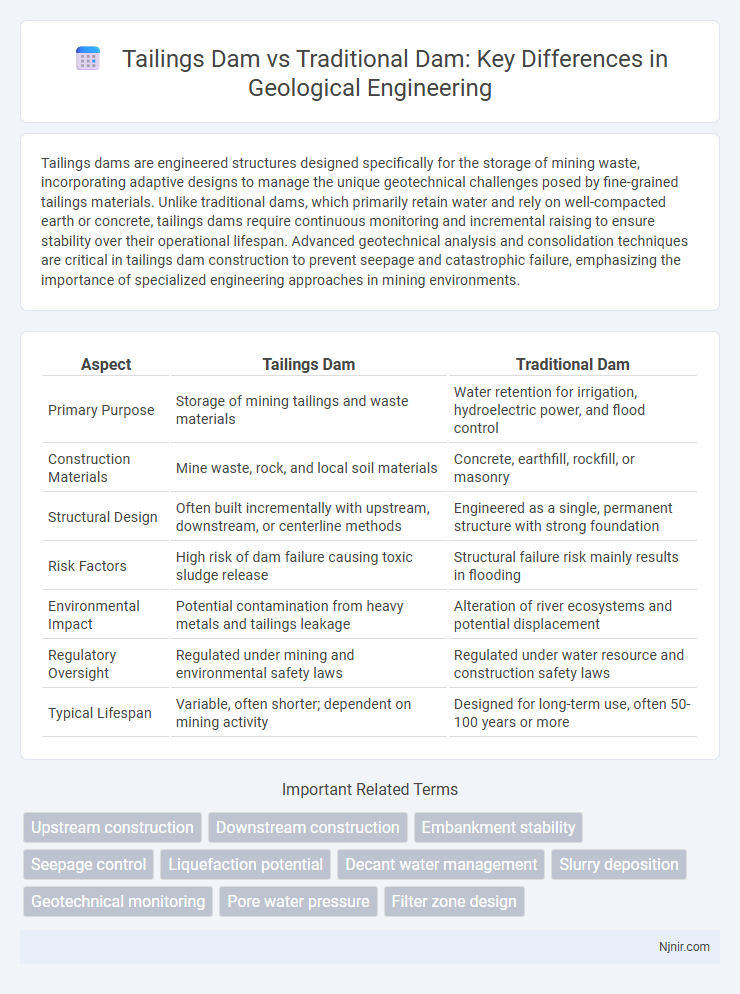

| Aspect | Tailings Dam | Traditional Dam |

|---|---|---|

| Primary Purpose | Storage of mining tailings and waste materials | Water retention for irrigation, hydroelectric power, and flood control |

| Construction Materials | Mine waste, rock, and local soil materials | Concrete, earthfill, rockfill, or masonry |

| Structural Design | Often built incrementally with upstream, downstream, or centerline methods | Engineered as a single, permanent structure with strong foundation |

| Risk Factors | High risk of dam failure causing toxic sludge release | Structural failure risk mainly results in flooding |

| Environmental Impact | Potential contamination from heavy metals and tailings leakage | Alteration of river ecosystems and potential displacement |

| Regulatory Oversight | Regulated under mining and environmental safety laws | Regulated under water resource and construction safety laws |

| Typical Lifespan | Variable, often shorter; dependent on mining activity | Designed for long-term use, often 50-100 years or more |

Introduction to Dam Types in Geological Engineering

Tailings dams are engineered structures designed to store byproducts of mining operations, primarily consisting of finely ground rock and water, whereas traditional dams generally retain water for purposes such as irrigation, hydroelectric power, and flood control. In geological engineering, tailings dams require specialized analysis of sedimentation, seepage control, and slope stability due to the heterogeneous and often unconsolidated nature of tailings material. Traditional dams typically involve reinforced concrete or earth-filled embankments with well-established design criteria focused on hydraulic pressure and geological foundation conditions.

Definition and Purpose of Tailings Dams

Tailings dams are engineered structures designed to store byproducts of mining operations, consisting mainly of fine-grained waste materials called tailings, which differ from traditional dams primarily built for water retention or hydroelectric power generation. Their purpose is to securely contain hazardous mining residues and prevent environmental contamination while facilitating water reclamation from tailings slurry. Unlike conventional dams that manage natural water flow, tailings dams require continuous monitoring and maintenance due to the risk of structural failure caused by the unsettled nature of tailings material.

Overview of Traditional Dams

Traditional dams, primarily constructed for water storage, flood control, and hydroelectric power generation, are engineered with materials such as concrete, earth, or rockfill to withstand hydraulic pressure and environmental forces. These structures require rigorous geotechnical analysis and design to ensure stability, seepage control, and long-term durability. Unlike tailings dams, which store mining byproducts and often involve raised embankments, traditional dams have a well-established safety monitoring framework to prevent catastrophic failures.

Construction Materials and Methods

Tailings dams are constructed primarily using mine waste materials such as sand, silt, and clay, which are deposited in layers to create embankments through upstream, downstream, or centerline methods. Traditional dams typically utilize engineered materials like concrete, earthfill, or rockfill, relying on precise compaction and structural reinforcement to ensure stability. Construction of tailings dams often involves progressive raising with deposited tailings, whereas traditional dams are built in a single, controlled phase focused on durability and water retention.

Geotechnical Design Considerations

Tailings dams require specialized geotechnical design considerations due to the unique properties of tailings, such as their fine particle size, low shear strength, and potential for liquefaction, unlike traditional dams built primarily of rock or compacted soil. The geotechnical stability of tailings dams depends heavily on the consolidation behavior and seepage control to prevent slope failures and catastrophic breaches. Traditional dams emphasize structural integrity through robust foundation support and gravity or arch principles, whereas tailings dams demand ongoing monitoring of pore water pressures and progressive upstream raises to maintain safety standards.

Environmental Impact Comparison

Tailings dams, used primarily for storing mining waste, pose significant environmental risks including potential toxic chemical leaks and long-term soil and water contamination compared to traditional dams that typically manage water resources with relatively lower chemical hazards. The failure of tailings dams often results in severe ecological damage and biodiversity loss due to the hazardous materials stored, while traditional dam failures mostly cause flooding and sediment displacement. Proper engineering and monitoring are crucial for tailings dams to minimize environmental impacts, whereas traditional dams focus more on hydroelectric power generation and water management sustainability.

Safety and Risk Management

Tailings dams require specialized safety protocols due to the potential for catastrophic failure caused by the unstable nature of mining waste materials and seismic events. Unlike traditional dams, which primarily manage water storage and flood control, tailings dams must address risks related to toxic slurry containment and chemical contamination. Advanced monitoring systems, regular structural assessments, and stringent regulatory compliance are essential for mitigating environmental and human health risks associated with tailings dam operations.

Regulatory Standards and Guidelines

Tailings dams are governed by specialized regulatory standards such as the International Commission on Large Dams (ICOLD) guidelines and the Mining Association of Canada's (MAC) Towards Sustainable Mining program, which emphasize stability, monitoring, and environmental impact specific to mine waste containment. Traditional dams follow broader civil engineering codes like the Federal Energy Regulatory Commission (FERC) regulations in the United States and the EU's Water Framework Directive, focusing on water retention, flood control, and hydroelectric power safety. Regulatory oversight for tailings dams prioritizes risk management for toxic slurry and long-term environmental monitoring, whereas traditional dam standards emphasize structural integrity, water quality, and public safety under variable hydrological conditions.

Challenges in Monitoring and Maintenance

Tailings dams pose significant challenges in monitoring and maintenance due to their often heterogeneous construction and the constantly changing properties of stored mine waste, which can compromise structural integrity. Traditional dams typically use well-documented engineering materials with predictable behavior, allowing for more straightforward monitoring through established methods like instrumentation and regular inspections. The dynamic nature of tailings dams necessitates advanced geotechnical monitoring technologies such as piezometers and remote sensing to detect seepage, deformation, and potential failure risks at an early stage.

Future Trends in Dam Engineering

Future trends in dam engineering emphasize advanced materials and real-time monitoring systems to enhance safety and sustainability for both tailings dams and traditional dams. Tailings dams are increasingly adopting remote sensing technology and predictive analytics to prevent failures associated with mining waste containment. Innovations like eco-friendly construction methods and adaptive design frameworks aim to minimize environmental impact while boosting resilience against climate change-induced stresses.

Upstream construction

Upstream construction of tailings dams involves raising the dam crest using previously deposited tailings, offering lower initial costs but higher risks of instability compared to the conventional downstream or centerline methods used in traditional dam engineering.

Downstream construction

Downstream construction in tailings dams enhances stability by building embankments progressively downstream, contrasting with traditional dams that often rely on upstream or centerline methods for foundation support.

Embankment stability

Tailings dams require specialized embankment stability measures due to their construction from mining byproducts, which often have lower shear strength and higher permeability compared to the engineered materials used in traditional dam embankments.

Seepage control

Tailings dams use layered filters and drainage blankets for seepage control, whereas traditional dams rely on impermeable clay cores or concrete cutoffs to minimize water infiltration.

Liquefaction potential

Tailings dams exhibit higher liquefaction potential than traditional dams due to their loose, saturated, fine-grained mine waste composition and seismic vulnerability.

Decant water management

Tailings dams use decant water management systems that recycle contaminated water to reduce environmental impact, whereas traditional dams primarily focus on water retention without specific decant water treatment processes.

Slurry deposition

Tailings dams use slurry deposition to store mining waste with fine particles, whereas traditional dams primarily manage water storage and flow without slurry.

Geotechnical monitoring

Geotechnical monitoring of tailings dams involves continuous assessment of pore pressure, slope stability, and settlement to prevent catastrophic failures, whereas traditional dams prioritize structural integrity and reservoir seepage control using established sensor networks and inspection protocols.

Pore water pressure

Tailings dams exhibit higher pore water pressure due to loose, fine-grained materials and seepage from tailings slurry compared to traditional dams constructed with compacted earth or rockfill.

Filter zone design

Tailings dam filter zone design prioritizes fine-grained materials for effective seepage control and stability, unlike traditional dam filter zones which utilize graded aggregates to prevent soil erosion and maintain structural integrity.

tailings dam vs traditional dam Infographic

njnir.com

njnir.com