Geosynthetic clay liners (GCLs) provide a natural clay core that offers superior sealing capabilities by swelling upon hydration, creating a low-permeability barrier essential in landfill and containment applications. Geomembranes, made from synthetic polymers such as HDPE or PVC, deliver high chemical resistance and mechanical strength, making them ideal for preventing fluid migration in harsh environments. Selecting between GCLs and geomembranes depends on site-specific conditions, with GCLs favoring low permeability needs and geomembranes excelling in durability and chemical resistance.

Table of Comparison

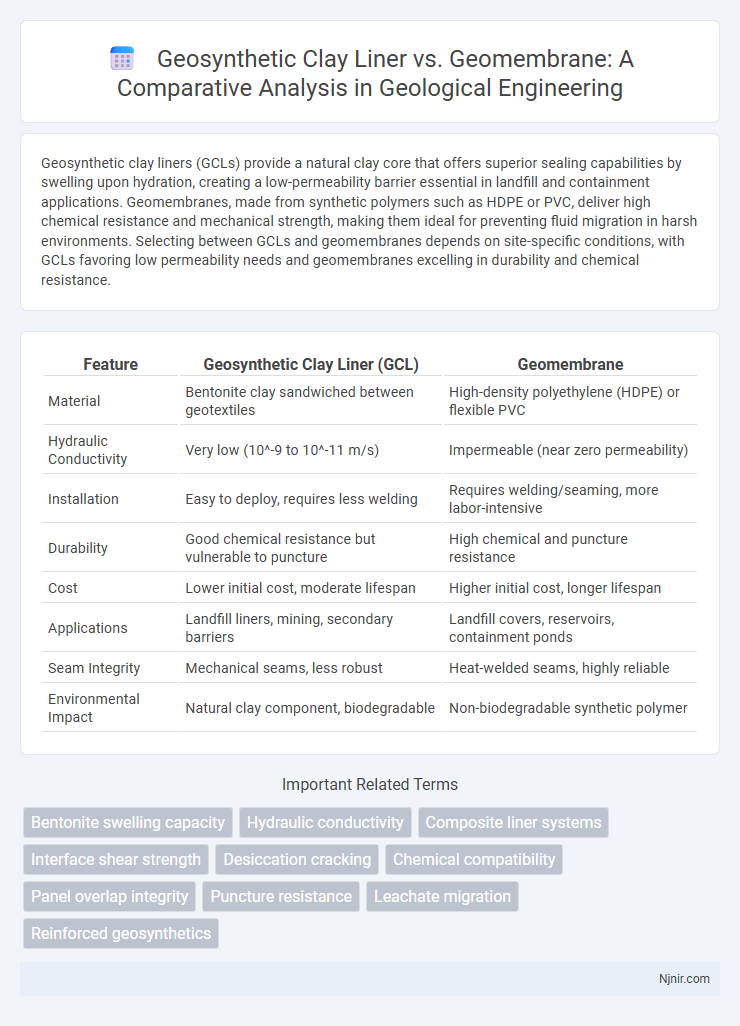

| Feature | Geosynthetic Clay Liner (GCL) | Geomembrane |

|---|---|---|

| Material | Bentonite clay sandwiched between geotextiles | High-density polyethylene (HDPE) or flexible PVC |

| Hydraulic Conductivity | Very low (10^-9 to 10^-11 m/s) | Impermeable (near zero permeability) |

| Installation | Easy to deploy, requires less welding | Requires welding/seaming, more labor-intensive |

| Durability | Good chemical resistance but vulnerable to puncture | High chemical and puncture resistance |

| Cost | Lower initial cost, moderate lifespan | Higher initial cost, longer lifespan |

| Applications | Landfill liners, mining, secondary barriers | Landfill covers, reservoirs, containment ponds |

| Seam Integrity | Mechanical seams, less robust | Heat-welded seams, highly reliable |

| Environmental Impact | Natural clay component, biodegradable | Non-biodegradable synthetic polymer |

Introduction to Geosynthetic Clay Liners and Geomembranes

Geosynthetic clay liners (GCLs) consist of a layer of bentonite clay sandwiched between geotextiles, providing low permeability and self-healing properties ideal for landfill liners and containment systems. Geomembranes are impermeable synthetic sheets, typically made from high-density polyethylene (HDPE), offering high resistance to chemical and environmental degradation for liquid containment applications. Both materials serve as critical components in environmental protection, with GCLs emphasizing natural clay properties and geomembranes focusing on engineered impermeability.

Material Composition and Structure

Geosynthetic clay liners (GCLs) consist of a layer of bentonite clay sandwiched between geotextiles or geomembranes, providing low permeability through the swelling properties of clay. Geomembranes are made from impermeable synthetic polymers such as high-density polyethylene (HDPE) or polyvinyl chloride (PVC), forming a continuous, flexible barrier. The structural difference lies in GCL's composite nature combining natural clay with synthetic layers, whereas geomembranes rely solely on polymer sheets for containment.

Key Performance Characteristics

Geosynthetic clay liners (GCLs) incorporate a bentonite clay layer that provides excellent hydraulic conductivity reduction, typically below 1x10^-9 m/s, ensuring superior leakage resistance. Geomembranes, composed of high-density polyethylene (HDPE) or other polymers, offer exceptional chemical resistance and tensile strength, with elongation values often exceeding 700%, making them highly durable under mechanical stress. While GCLs excel in self-sealing capabilities and ease of installation on uneven surfaces, geomembranes outperform in UV resistance and long-term durability in exposed environments.

Installation Methods and Procedures

Geosynthetic clay liners (GCLs) are installed by unrolling the pre-fabricated rolls over prepared subgrades, followed by overlapping and seaming using bentonite or adhesives to ensure hydraulic conductivity is minimized. Geomembranes require welding techniques such as hot wedge or extrusion welding to join adjacent panels, with strict quality control measures to prevent punctures and seams defects. Proper surface preparation, anchoring, and inspection are critical in both installation processes to maintain liner integrity and achieve effective containment in environmental and geotechnical applications.

Hydraulic Performance and Seepage Control

Geosynthetic clay liners (GCLs) provide superior hydraulic performance through their natural sodium bentonite core, which swells upon hydration to create an ultra-low permeability barrier, typically less than 1x10^-9 cm/s. Geomembranes, composed of high-density polyethylene (HDPE) or other polymers, offer near-zero permeability but rely on installation integrity to prevent leaks, making them highly effective for seepage control in engineered barriers. The choice between GCL and geomembrane depends on site-specific conditions, with GCLs excelling in self-sealing properties and geomembranes providing robust, durable impermeability when properly anchored and maintained.

Chemical and Biological Compatibility

Geosynthetic clay liners (GCLs) exhibit superior chemical compatibility due to their bentonite core, which swells upon contact with water to form a low-permeability barrier resistant to a wide range of heavy metals, organic solvents, and acidic or alkaline leachates. Geomembranes, primarily composed of high-density polyethylene (HDPE) or polyvinyl chloride (PVC), offer excellent biological resistance by resisting microbial degradation but can be vulnerable to chemical permeation from certain solvents and oils. Selecting between GCLs and geomembranes depends on the specific chemical composition and biodegradability of the contained waste, as GCLs are preferable for chemically aggressive environments, whereas geomembranes are optimal for biological contamination resistance.

Durability and Long-Term Performance

Geosynthetic clay liners (GCLs) offer excellent self-sealing properties and chemical resistance, making them highly durable in landfill and containment applications. Geomembranes, typically made from high-density polyethylene (HDPE), provide superior puncture and tear resistance with proven longevity exceeding 30 years in harsh environments. Combining GCLs with geomembranes enhances overall system performance by leveraging the self-healing capacity of bentonite clay and the mechanical strength of synthetic liners for long-term containment integrity.

Cost Analysis and Economic Considerations

Geosynthetic clay liners (GCLs) generally offer lower initial installation costs compared to geomembranes due to simpler deployment and reduced requirement for welding or seaming. However, geomembranes often provide better long-term durability and resistance to chemical degradation, potentially reducing maintenance and replacement expenses over time. Economic considerations must balance upfront savings of GCLs against lifecycle costs, including performance, maintenance, and environmental conditions of the project site.

Environmental Applications and Case Studies

Geosynthetic clay liners (GCLs) offer superior containment by combining natural bentonite clay with synthetic materials, providing effective impermeability in landfill liners and mining waste covers. Geomembranes, typically made from high-density polyethylene (HDPE), excel in chemical resistance and durability, widely utilized in hazardous waste containment and wastewater treatment facilities. Case studies reveal GCLs' success in reducing leachate migration in municipal solid waste landfills, while geomembranes demonstrate long-term performance in tailings dams and contaminated site remediation projects.

Selection Criteria and Design Recommendations

Geosynthetic clay liners (GCLs) offer superior self-healing properties and excellent low permeability for landfill lining, making them ideal for projects requiring enhanced chemical resistance and hydraulic containment. Geomembranes provide high tensile strength and puncture resistance, favoring applications demanding robust mechanical durability and flexible installation over varied substrates. Selection criteria hinge on site-specific factors such as chemical exposure, load conditions, and installation constraints, while design recommendations emphasize compatibility with waste characteristics, proper anchorage, and integration with drainage layers to ensure long-term containment performance.

Bentonite swelling capacity

Geosynthetic clay liners (GCLs) utilize Bentonite's high swelling capacity to create an impermeable seal by expanding upon hydration, whereas geomembranes rely on synthetic materials that do not exhibit swelling properties.

Hydraulic conductivity

Geosynthetic clay liners exhibit significantly lower hydraulic conductivity, typically around 1x10^-11 m/s, compared to geomembranes, which have near zero permeability but may develop leaks, making GCLs highly effective for controlling fluid migration in landfill liners.

Composite liner systems

Composite liner systems combine a geosynthetic clay liner (GCL) and a geomembrane to provide enhanced impermeability, chemical resistance, and mechanical durability for landfill and environmental containment applications.

Interface shear strength

Geosynthetic clay liners exhibit lower interface shear strength compared to geomembranes, making geomembranes more suitable for applications requiring higher shear resistance in landfill liners and containment systems.

Desiccation cracking

Geosynthetic clay liners exhibit lower desiccation cracking vulnerability compared to geomembranes, enhancing their effectiveness in maintaining hydraulic barriers in landfill and environmental containment applications.

Chemical compatibility

Geosynthetic clay liners exhibit superior chemical compatibility with a wide range of hazardous liquids compared to geomembranes, which may degrade or lose effectiveness when exposed to certain chemicals.

Panel overlap integrity

Geosynthetic clay liners maintain panel overlap integrity through natural swelling of bentonite clay creating a self-sealing barrier, whereas geomembranes rely on mechanical seams or heat welding that require precise installation for durable overlap integrity.

Puncture resistance

Geosynthetic clay liners exhibit superior puncture resistance compared to geomembranes due to their composite structure combining bentonite clay and geotextiles, enhancing durability in landfill and containment applications.

Leachate migration

Geosynthetic clay liners significantly reduce leachate migration due to their low permeability and self-sealing properties, whereas geomembranes provide a more impermeable barrier but are susceptible to punctures and seam failures that can increase leachate leakage.

Reinforced geosynthetics

Reinforced geosynthetics enhance the durability and tensile strength of geosynthetic clay liners compared to geomembranes, making them more effective for long-term containment in landfill and environmental protection applications.

geosynthetic clay liner vs geomembrane Infographic

njnir.com

njnir.com