The point load test provides a rapid and cost-effective method to estimate rock strength, especially useful in field conditions where sample preparation is limited, while the uniaxial compressive test offers more precise and detailed strength parameters under controlled laboratory conditions. The point load index correlates well with uniaxial compressive strength but is generally less accurate due to its indirect testing nature and variability in sample size and shape. Selecting between these tests depends on project requirements, budget constraints, and the accuracy needed for geotechnical design and rock mass characterization.

Table of Comparison

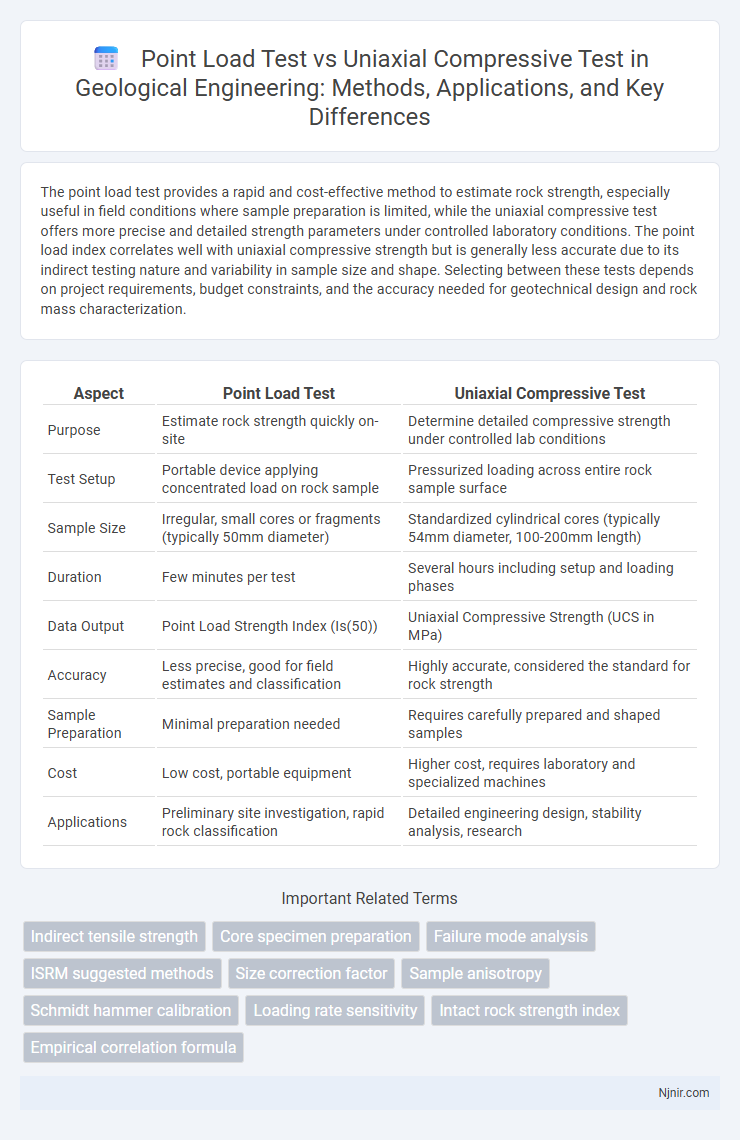

| Aspect | Point Load Test | Uniaxial Compressive Test |

|---|---|---|

| Purpose | Estimate rock strength quickly on-site | Determine detailed compressive strength under controlled lab conditions |

| Test Setup | Portable device applying concentrated load on rock sample | Pressurized loading across entire rock sample surface |

| Sample Size | Irregular, small cores or fragments (typically 50mm diameter) | Standardized cylindrical cores (typically 54mm diameter, 100-200mm length) |

| Duration | Few minutes per test | Several hours including setup and loading phases |

| Data Output | Point Load Strength Index (Is(50)) | Uniaxial Compressive Strength (UCS in MPa) |

| Accuracy | Less precise, good for field estimates and classification | Highly accurate, considered the standard for rock strength |

| Sample Preparation | Minimal preparation needed | Requires carefully prepared and shaped samples |

| Cost | Low cost, portable equipment | Higher cost, requires laboratory and specialized machines |

| Applications | Preliminary site investigation, rapid rock classification | Detailed engineering design, stability analysis, research |

Introduction to Rock Strength Testing in Geological Engineering

Point load test and uniaxial compressive test are fundamental methods used in geological engineering to evaluate rock strength, which is critical for designing stable structures and assessing rock mass integrity. The point load test is a quick, portable, and cost-effective method that estimates strength by applying a concentrated load until failure, making it useful for preliminary field assessments and irregular rock samples. In contrast, the uniaxial compressive test provides more precise and standardized measurements by applying axial load to cylindrical specimens under controlled laboratory conditions, offering detailed data on rock strength parameters essential for engineering and geotechnical analysis.

Overview of Point Load Test

The Point Load Test is a quick and inexpensive method for estimating the uniaxial compressive strength of rock samples by applying a concentrated load at failure points. It provides a convenient alternative to the uniaxial compressive test when sample size or preparation limits. The test is widely used in preliminary site investigations and quality control due to its portability and minimal equipment requirements.

Overview of Uniaxial Compressive Test

The uniaxial compressive test measures the maximum compressive strength of a material by applying a controlled load along a single axis until failure occurs, providing critical data on material behavior under compression. This test is essential for evaluating the mechanical properties of concrete, metals, and rocks, delivering values such as compressive strength, elastic modulus, and failure strain. Unlike the point load test, which is a quick field method offering approximate strength values, the uniaxial compressive test provides precise, standardized, and highly reliable strength assessments for structural design and engineering applications.

Principles and Methodology of Point Load Test

The Point Load Test measures rock strength by applying a concentrated load on a rock sample until failure, simulating stress conditions at a single point, which is efficient for quick field assessments. The test involves placing the rock specimen between two pointed platens and increasing the load until it fractures, providing a point load index that correlates with uniaxial compressive strength. Unlike the Uniaxial Compressive Test, which applies uniform axial stress on prepared cylindrical samples in a controlled laboratory setting, the Point Load Test requires minimal sample preparation and is versatile for irregular rocks.

Principles and Methodology of Uniaxial Compressive Test

The Uniaxial Compressive Test measures compressive strength by applying a controlled axial load to a cylindrical specimen until failure, recording stress-strain behavior to determine mechanical properties such as modulus of elasticity and peak strength. The methodology involves preparing standardized specimens, aligning them in a testing machine, and gradually increasing axial load while ensuring uniform stress distribution and preventing buckling. This test contrasts with Point Load Test, which uses concentrated loading on irregular samples to estimate strength rapidly, but with less precision and detail on stress-strain characteristics.

Comparative Analysis: Point Load Test vs. Uniaxial Compressive Test

The Point Load Test provides a rapid, indirect estimate of rock strength by applying concentrated load until failure, making it useful for field conditions and preliminary assessments. The Uniaxial Compressive Test (UCT) offers precise measurements of rock strength under controlled laboratory conditions by applying axial load until fracture, delivering detailed stress-strain data critical for engineering design. While the Point Load Test is less accurate and influenced by sample size and shape, the UCT remains the standard for determining exact uniaxial compressive strength and deformation properties essential for structural evaluation.

Applications of Point Load and Uniaxial Compressive Tests

Point load tests are widely applied in preliminary rock strength assessments and field investigations due to their rapid and non-destructive nature, enabling quick estimation of rock quality index (RQI) and strength classification. Uniaxial compressive tests provide precise measurements of rock strength and deformability, essential for detailed engineering design in tunneling, slope stability analysis, and foundation construction. The point load test serves as an efficient proxy to approximate uniaxial compressive strength in inaccessible or large-scale rock masses where core samples for compressive testing are impractical.

Advantages and Limitations of Each Test Method

The point load test offers rapid, in-situ estimation of rock strength with minimal sample preparation, making it practical for preliminary site assessments; however, it provides less precise strength values and is sensitive to sample size and shape. The uniaxial compressive strength (UCS) test delivers highly accurate and consistent measurements of rock strength under controlled laboratory conditions, ideal for detailed engineering design, but requires carefully prepared cylindrical samples and is time-consuming and labor-intensive. Each method balances speed and accuracy differently, with the point load test suited for quick evaluations and the UCS test essential for comprehensive strength characterization.

Data Interpretation and Correlation Between Tests

Data interpretation from point load tests often involves using empirical correlations to estimate uniaxial compressive strength (UCS), relying on the point load index (Is) as a predictor. Uniaxial compressive tests directly measure UCS by applying axial load until failure, providing precise and standardized strength values for rock samples. Correlation between these tests varies by rock type and condition, with point load tests serving as a rapid, approximate method while UCS tests confirm strength parameters essential for engineering design.

Current Trends and Future Prospects in Rock Strength Testing

Recent advancements in rock strength testing emphasize enhanced accuracy and efficiency in point load and uniaxial compressive tests through digital sensors, automated data acquisition, and machine learning algorithms for predictive analysis. Integration of non-destructive testing methods alongside traditional mechanical tests is propelling the development of hybrid techniques, improving the reliability of strength estimation in complex rock formations. Future prospects include AI-driven real-time monitoring systems and nano-scale material characterization, enabling precise assessment of rock behavior under varied stress conditions for infrastructure and mining applications.

Indirect tensile strength

Point load test provides a rapid estimation of indirect tensile strength, correlating closely with uniaxial compressive test results for rock and concrete materials.

Core specimen preparation

Core specimen preparation for point load tests requires minimal machining and can utilize irregular shapes, while uniaxial compressive tests demand precisely shaped cylindrical cores with parallel ends to ensure accurate stress application.

Failure mode analysis

The point load test primarily induces localized failure characterized by tensile fracturing near the load application point, while the uniaxial compressive test typically results in axial splitting and shear failure modes reflecting the material's compressive strength.

ISRM suggested methods

The ISRM suggests the Point Load Test for rapid strength estimation on irregular rock samples and the Uniaxial Compressive Strength Test for precise strength measurement on standardized core specimens.

Size correction factor

The size correction factor in point load tests adjusts strength measurements to equivalent uniaxial compressive strength values by accounting for sample dimensions, ensuring accurate comparison between tests.

Sample anisotropy

Point load tests provide quicker estimates of rock strength with less influence from sample anisotropy compared to uniaxial compressive tests, which are more sensitive to directional variations in rock properties.

Schmidt hammer calibration

Schmidt hammer calibration is essential for correlating point load test results with uniaxial compressive strength to ensure accurate and reliable rock strength assessments.

Loading rate sensitivity

The point load test exhibits greater sensitivity to loading rate variations compared to the uniaxial compressive test, significantly affecting strength measurements.

Intact rock strength index

The point load test provides an indirect estimation of the intact rock strength index by measuring the load at failure of rock samples, whereas the uniaxial compressive test delivers a direct and more precise measurement of the intact rock strength index under controlled axial stress conditions.

Empirical correlation formula

Empirical correlation formulas link point load test strength index (Is) to uniaxial compressive strength (UCS) through equations like UCS = k * Is^n, where k and n are rock type-dependent constants enabling rapid estimation of UCS from point load test results.

point load test vs uniaxial compressive test Infographic

njnir.com

njnir.com