Fracture toughness measures a material's ability to resist crack propagation, which is critical in geological engineering for assessing rock stability under stress. Tensile strength quantifies the maximum tensile load a rock can withstand before failure, essential for evaluating rock strength in excavation and construction projects. Understanding the interplay between fracture toughness and tensile strength allows engineers to predict failure patterns and design safer, more effective underground structures.

Table of Comparison

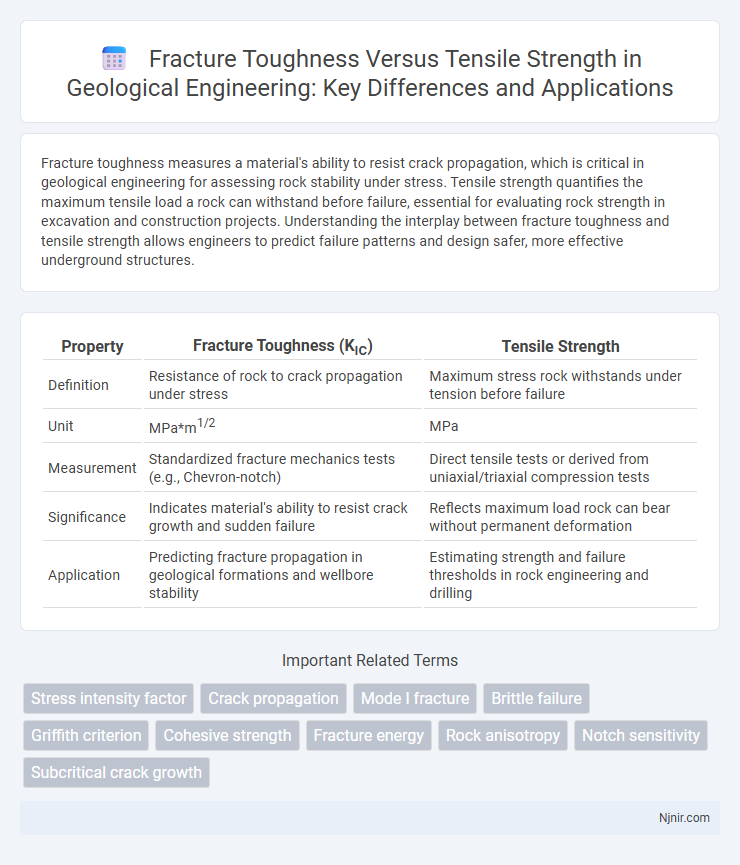

| Property | Fracture Toughness (KIC) | Tensile Strength |

|---|---|---|

| Definition | Resistance of rock to crack propagation under stress | Maximum stress rock withstands under tension before failure |

| Unit | MPa*m1/2 | MPa |

| Measurement | Standardized fracture mechanics tests (e.g., Chevron-notch) | Direct tensile tests or derived from uniaxial/triaxial compression tests |

| Significance | Indicates material's ability to resist crack growth and sudden failure | Reflects maximum load rock can bear without permanent deformation |

| Application | Predicting fracture propagation in geological formations and wellbore stability | Estimating strength and failure thresholds in rock engineering and drilling |

Introduction to Fracture Toughness and Tensile Strength

Fracture toughness measures a material's ability to resist crack propagation under stress, while tensile strength defines the maximum stress a material can withstand before failure. Understanding these mechanical properties is crucial for predicting material performance in structural applications. Materials with high fracture toughness often exhibit enhanced durability, even if their tensile strength is moderate.

Fundamental Concepts in Geological Engineering

Fracture toughness measures a geological material's resistance to crack propagation under stress, an essential parameter for evaluating rock stability and durability. Tensile strength quantifies the maximum stress a rock can withstand when subjected to tension before failure, influencing the design of underground excavations and slope stability. Understanding the relationship between fracture toughness and tensile strength aids in predicting fracture behavior and mechanical performance in geological engineering applications.

Defining Fracture Toughness in Geological Materials

Fracture toughness in geological materials measures their resistance to crack propagation under stress, reflecting the critical stress intensity factor that indicates the onset of fracture. Unlike tensile strength, which quantifies the maximum stress a material can withstand before failure, fracture toughness focuses on the energy required to propagate existing cracks. This property is crucial for understanding rock stability, especially in applications like mining, civil engineering, and earthquake mechanics.

Understanding Tensile Strength in Rocks and Soils

Tensile strength in rocks and soils measures their resistance to breaking under tension, reflecting the internal cohesion and mineral bonding. Unlike fracture toughness, which quantifies a material's ability to resist crack propagation, tensile strength provides insight into the maximum stress that soils and rocks can withstand before failure. Accurate evaluation of tensile strength is crucial for geotechnical engineering applications such as slope stability, foundation design, and seismic response analysis.

Laboratory Methods for Measuring Fracture Toughness

Laboratory methods for measuring fracture toughness include standardized tests such as ASTM E399 and ASTM E1820, which assess critical stress intensity factors in controlled environments. These methods involve preparing specimens with pre-cracks and applying tensile loading to determine the material's resistance to crack propagation. Fracture toughness testing provides crucial data on a material's ability to resist crack growth, complementing tensile strength measurements that quantify maximum stress before failure without crack considerations.

Experimental Techniques for Tensile Strength Assessment

Experimental techniques for tensile strength assessment typically involve uniaxial tensile testing, where a specimen is subjected to controlled tension until failure, measuring the maximum stress it can withstand. Standardized methods such as ASTM E8/E8M use extensometers or strain gauges to accurately capture stress-strain behavior, enabling precise tensile strength determination. Compared to fracture toughness testing, tensile strength experiments emphasize uniform deformation and material ductility under tension without pre-crack propagation.

Factors Influencing Fracture Toughness and Tensile Strength

Fracture toughness and tensile strength are influenced by material composition, microstructure, temperature, and the presence of flaws or defects. Grain size refinement, alloying elements, and heat treatment can enhance fracture toughness by hindering crack propagation, while tensile strength is primarily affected by dislocation density and strain hardening. Environmental factors such as corrosion and loading rate also play critical roles in altering both fracture toughness and tensile strength.

Comparative Analysis: Fracture Toughness vs. Tensile Strength

Fracture toughness measures a material's ability to resist crack propagation, while tensile strength gauges the maximum stress a material can withstand before failure. In comparative analysis, fracture toughness is crucial for evaluating performance under impact or stress concentration, whereas tensile strength primarily indicates overall load-bearing capacity. Materials with high tensile strength might exhibit low fracture toughness, highlighting the importance of assessing both properties for applications requiring durability and damage tolerance.

Practical Implications in Rock Mechanics and Engineering Design

Fracture toughness in rock mechanics determines a material's resistance to crack propagation, crucial for predicting failure in rock formations under stress, whereas tensile strength measures the maximum stress a rock can withstand before fracturing. Incorporating fracture toughness into engineering design enables more accurate modeling of crack growth and stability in tunnels, slopes, and foundations, improving safety and durability. Understanding the interplay between these properties guides the selection of excavation methods and support systems by anticipating fracture behavior under varying load conditions.

Future Trends in Testing and Application

Future trends in fracture toughness and tensile strength testing emphasize advanced non-destructive evaluation techniques like ultrasonic phased array and digital image correlation for more accurate, real-time material behavior analysis. Integration of AI-driven data analytics enhances predictive modeling of failure mechanisms under complex loading conditions, optimizing material design for aerospace, automotive, and structural applications. The development of nanostructured composites with tailored fracture toughness and tensile strength properties promises significant improvements in durability and weight reduction across various industries.

Stress intensity factor

Fracture toughness, measured by the critical stress intensity factor (K_IC), defines a material's resistance to crack propagation, whereas tensile strength indicates the maximum stress a material can withstand before failure.

Crack propagation

Fracture toughness measures a material's resistance to crack propagation under stress, while tensile strength indicates the maximum stress a material can withstand before failure.

Mode I fracture

Mode I fracture toughness (K_IC) quantifies a material's resistance to crack propagation under tensile stress, while tensile strength measures the maximum stress a material can withstand before failure, both critical parameters in predicting fracture behavior in brittle materials.

Brittle failure

Fracture toughness measures a material's resistance to crack propagation while tensile strength indicates the maximum stress before failure, with brittle materials exhibiting low fracture toughness and fracturing suddenly near their tensile strength.

Griffith criterion

The Griffith criterion explains fracture toughness as a function of tensile strength and flaw size, defining the critical stress at which a crack propagates in brittle materials.

Cohesive strength

Cohesive strength directly influences fracture toughness by determining a material's resistance to crack propagation compared to its tensile strength, which measures the maximum stress before failure.

Fracture energy

Fracture energy, a critical measure of a material's ability to absorb energy before failure, directly influences fracture toughness and often provides a more comprehensive assessment of resistance to crack propagation than tensile strength.

Rock anisotropy

Rock anisotropy significantly influences fracture toughness and tensile strength by causing directional variations in mechanical properties that affect crack initiation and propagation.

Notch sensitivity

Notch sensitivity significantly reduces fracture toughness compared to tensile strength by concentrating stress at flaws, increasing the likelihood of crack initiation and propagation.

Subcritical crack growth

Subcritical crack growth reduces fracture toughness despite high tensile strength by enabling gradual crack propagation under stress below the critical threshold.

fracture toughness vs tensile strength Infographic

njnir.com

njnir.com