Grouting involves injecting cementitious or chemical materials into soil or rock to improve strength and reduce permeability, making it ideal for sealing cracks or stabilizing weak ground. Soil nailing reinforces slopes and excavations by installing steel bars into pre-drilled holes, enhancing stability through passive soil confinement. Both techniques enhance ground support but differ in application scope, material use, and cost-effectiveness depending on project requirements.

Table of Comparison

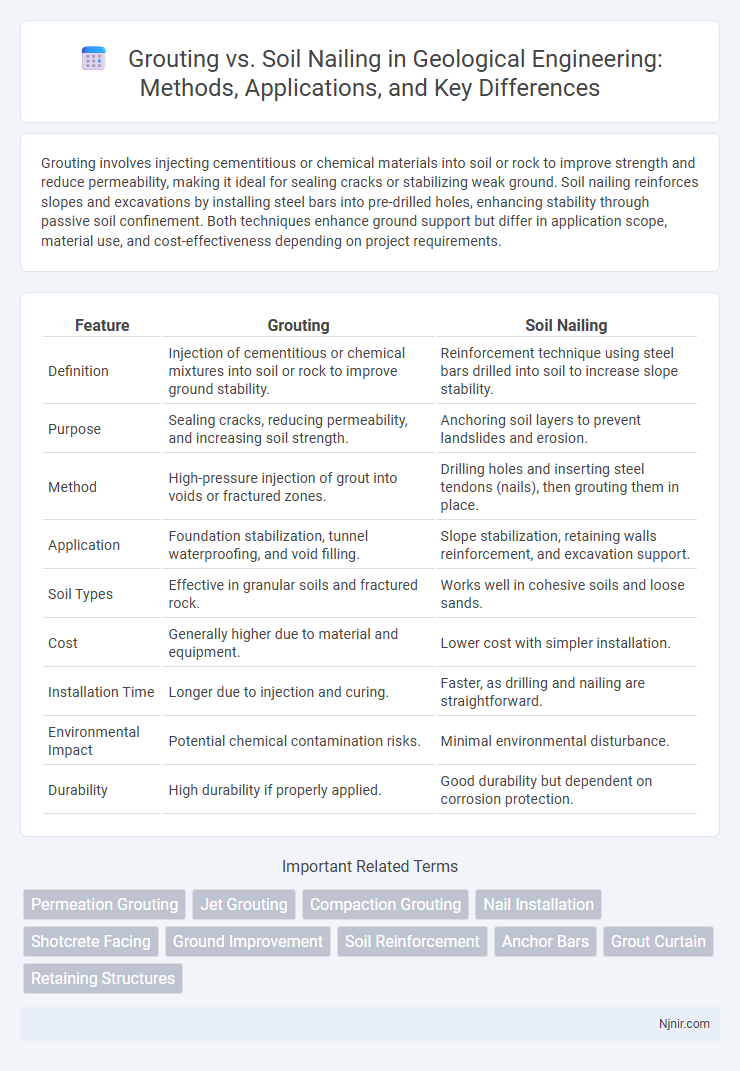

| Feature | Grouting | Soil Nailing |

|---|---|---|

| Definition | Injection of cementitious or chemical mixtures into soil or rock to improve ground stability. | Reinforcement technique using steel bars drilled into soil to increase slope stability. |

| Purpose | Sealing cracks, reducing permeability, and increasing soil strength. | Anchoring soil layers to prevent landslides and erosion. |

| Method | High-pressure injection of grout into voids or fractured zones. | Drilling holes and inserting steel tendons (nails), then grouting them in place. |

| Application | Foundation stabilization, tunnel waterproofing, and void filling. | Slope stabilization, retaining walls reinforcement, and excavation support. |

| Soil Types | Effective in granular soils and fractured rock. | Works well in cohesive soils and loose sands. |

| Cost | Generally higher due to material and equipment. | Lower cost with simpler installation. |

| Installation Time | Longer due to injection and curing. | Faster, as drilling and nailing are straightforward. |

| Environmental Impact | Potential chemical contamination risks. | Minimal environmental disturbance. |

| Durability | High durability if properly applied. | Good durability but dependent on corrosion protection. |

Introduction to Ground Improvement Techniques

Grouting enhances ground stability by injecting cementitious or chemical materials to fill voids and increase soil strength, making it effective for soil stabilization and reducing permeability. Soil nailing reinforces existing slopes and excavations through the insertion of steel bars, improving shear strength and slope stability in weak soils. Both techniques are essential ground improvement methods tailored to specific geotechnical challenges, optimizing site safety and structural support.

Overview of Grouting in Geological Engineering

Grouting in geological engineering involves injecting fluid materials, such as cement or chemical solutions, into soil or rock formations to improve strength and reduce permeability. This technique stabilizes weak ground by filling voids, cracks, and fissures, enhancing load-bearing capacity and controlling groundwater flow. Grouting is vital for foundation support, tunnel reinforcement, and mitigating landslide risks in challenging geological conditions.

Fundamentals of Soil Nailing

Soil nailing involves the installation of steel bars or tendons into a slope or excavation to reinforce and stabilize the soil by creating a composite mass that resists movement. This technique relies on the soil's existing strength and introduces tensile reinforcement to increase stability without extensive excavation. Grouting, often used alongside soil nailing, enhances bond strength between the soil and nails by injecting cementitious material to fill voids and improve load transfer.

Grouting Methods and Applications

Grouting methods include permeation, compaction, and chemical grouting, each tailored for specific soil stabilization needs by injecting grout materials into soil voids to improve strength and reduce permeability. Permeation grouting is ideal for granular soils to fill voids without soil displacement, while compaction grouting densifies loose soils by displacing weaker material. Applications span foundation underpinning, seepage control in dams, and void filling in underground excavations, making grouting a versatile technique for enhancing soil stability and load-bearing capacity.

Soil Nailing Design and Installation

Soil nailing design involves the strategic placement of steel bars, or nails, drilled and grouted into a soil mass to reinforce and stabilize slopes or retaining structures. Installation requires careful drilling to precise depths, followed by the insertion of corrosion-resistant bars and high-strength grout to bond the soil and provide structural support. Optimal soil nailing enhances slope stability by increasing soil shear strength and reducing deformation, often monitored using instrumentation for performance assessment.

Comparative Analysis: Grouting vs Soil Nailing

Grouting enhances soil strength by injecting cementitious materials to fill voids and fractures, improving ground stability and reducing permeability, while soil nailing reinforces slopes or excavations through the insertion of steel bars to anchor soil layers. Grouting is typically used for ground improvement under foundations and tunnels where impermeability is critical, whereas soil nailing offers flexible, cost-effective slope stabilization in cut slopes and retaining structures. The choice between grouting and soil nailing depends on project-specific factors such as soil type, load requirements, environmental conditions, and long-term durability needs.

Material and Equipment Requirements

Grouting requires specialized cementitious or chemical materials mixed on-site with high-pressure pumps and injection equipment to fill soil voids and fractures, ensuring soil stabilization. Soil nailing involves steel bars or rods driven into pre-drilled holes, secured with grout or resin, and typically requires drilling rigs, grout mixers, and tensioning devices for installation. The material choice and equipment for grouting emphasize fluid injection and permeability control, while soil nailing demands rigid reinforcement elements and precise drilling machinery.

Performance and Effectiveness in Slope Stabilization

Grouting enhances slope stability by injecting cementitious materials to fill voids and increase soil cohesion, providing high durability and reduced permeability especially in rock and fractured formations. Soil nailing reinforces slopes through the insertion of steel bars, improving shear strength and slope performance by creating a composite soil-nail mass ideal for retaining wall support and steep embankments. While grouting excels in soil consolidation and sealing, soil nailing offers flexible, cost-effective reinforcement with faster installation and adaptability to variable soil conditions.

Environmental and Economic Considerations

Grouting techniques often require chemical materials that can pose environmental risks through potential groundwater contamination, whereas soil nailing utilizes steel bars with minimal chemical use, resulting in a lower environmental footprint. Economically, soil nailing generally offers cost savings due to reduced material and labor expenses compared to grouting, which involves specialized equipment and chemical procurement. Both methods demand site-specific assessments, but soil nailing tends to be favored for projects emphasizing sustainability and budget efficiency.

Case Studies: Successful Projects

Case studies reveal that grouting effectively stabilizes loose soils in tunnel construction, as demonstrated by the Gotthard Base Tunnel project, where cementitious grouting enhanced ground strength and minimized water ingress. Soil nailing has proven successful in slope stabilization for the US Highway 50 improvement, increasing slope stability by reinforcing existing soil with steel bars and improving load distribution. Comparative analysis shows grouting is preferred for deep, localized ground improvement, while soil nailing excels in reinforcing shallow slopes and preventing erosion.

Permeation Grouting

Permeation grouting enhances soil strength by injecting low-viscosity grout into soil pores, contrasting with soil nailing that reinforces soil through installed nails for slope stability.

Jet Grouting

Jet grouting offers superior soil stabilization by injecting high-pressure grout to create in-situ cemented columns, contrasting with soil nailing which reinforces existing soil through steel bars.

Compaction Grouting

Compaction grouting stabilizes loose soils by injecting a stiff grout mix to densify and strengthen the ground, offering distinct advantages over soil nailing in terms of ground improvement and load-bearing capacity.

Nail Installation

Grouting in nail installation involves injecting cementitious materials to stabilize soil around the nail, while soil nailing mechanically anchors steel bars directly into pre-drilled holes to reinforce slope stability.

Shotcrete Facing

Shotcrete facing in soil nailing provides immediate structural support and surface stabilization, while grouting primarily enhances soil strength and reduces permeability without offering the same surface reinforcement benefits.

Ground Improvement

Grouting enhances ground improvement by injecting cementitious or chemical materials to increase soil strength and reduce permeability, while soil nailing stabilizes slopes and excavations by reinforcing the soil with steel bars embedded in drilled holes.

Soil Reinforcement

Soil nailing offers efficient soil reinforcement by installing closely spaced steel bars to stabilize slopes, while grouting enhances soil strength through the injection of cementitious materials to fill voids and reduce permeability.

Anchor Bars

Anchor bars in grouting provide enhanced load transfer through cementitious materials, while in soil nailing they reinforce soil stability by directly anchoring into the ground.

Grout Curtain

Grout curtains enhance soil stability and water cutoff by creating impermeable barriers through deep soil injection, making them essential in grouting compared to soil nailing for effective groundwater control.

Retaining Structures

Grouting enhances soil strength by injecting cementitious materials to fill voids in retaining structures, while soil nailing stabilizes slopes through steel bars inserted into the soil to provide reinforcement and prevent movement.

Grouting vs Soil nailing Infographic

njnir.com

njnir.com