Rippability assessment evaluates the ease with which rock can be broken and excavated using mechanical ripping equipment, relying heavily on factors such as rock strength, uniaxial compressive strength, and fracturing. Blastability assessment, on the other hand, focuses on the suitability of rock for controlled blasting, considering parameters like rock density, joint spacing, and explosive properties. Understanding the distinct criteria in rippability versus blastability assessments enables geological engineers to optimize excavation strategies, balancing cost-efficiency and operational safety.

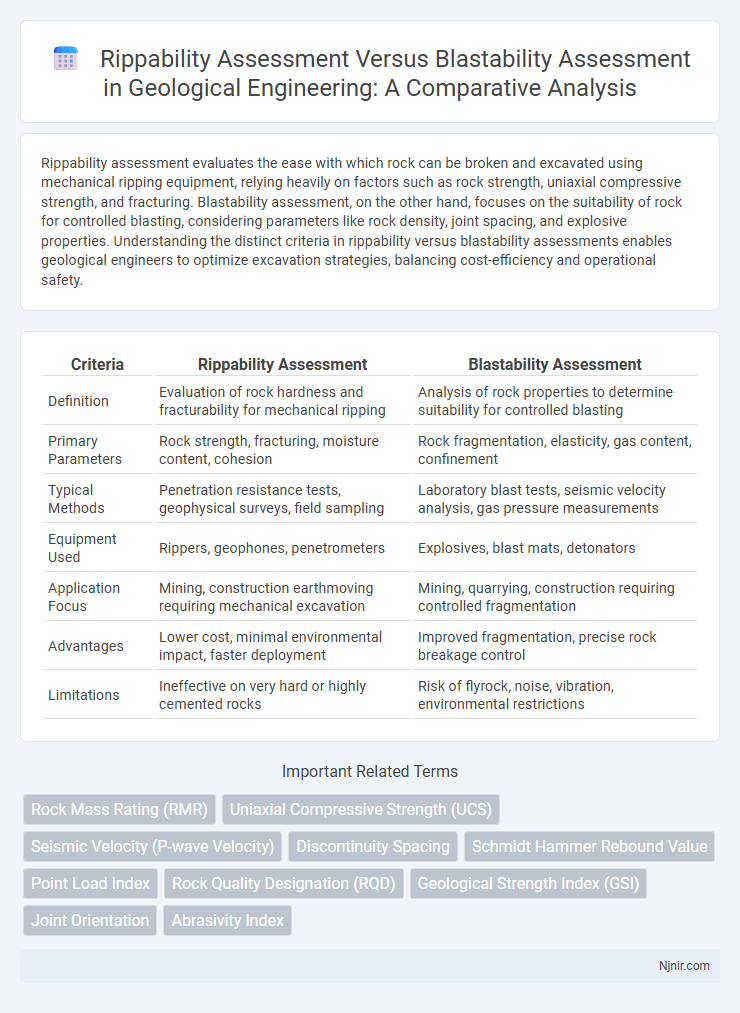

Table of Comparison

| Criteria | Rippability Assessment | Blastability Assessment |

|---|---|---|

| Definition | Evaluation of rock hardness and fracturability for mechanical ripping | Analysis of rock properties to determine suitability for controlled blasting |

| Primary Parameters | Rock strength, fracturing, moisture content, cohesion | Rock fragmentation, elasticity, gas content, confinement |

| Typical Methods | Penetration resistance tests, geophysical surveys, field sampling | Laboratory blast tests, seismic velocity analysis, gas pressure measurements |

| Equipment Used | Rippers, geophones, penetrometers | Explosives, blast mats, detonators |

| Application Focus | Mining, construction earthmoving requiring mechanical excavation | Mining, quarrying, construction requiring controlled fragmentation |

| Advantages | Lower cost, minimal environmental impact, faster deployment | Improved fragmentation, precise rock breakage control |

| Limitations | Ineffective on very hard or highly cemented rocks | Risk of flyrock, noise, vibration, environmental restrictions |

Understanding Rippability Assessment in Geological Engineering

Rippability assessment in geological engineering evaluates the ease of breaking rock formations using mechanical ripping equipment based on rock strength, fracturing, and abrasiveness, enabling cost-effective excavation planning. Blastability assessment, by contrast, determines the suitability and design parameters for using explosives, considering factors like rock composition, density, and fracture patterns to optimize fragmentation. Understanding rippability involves analyzing geotechnical parameters such as uniaxial compressive strength, rock mass rating (RMR), and discontinuity spacing to predict excavation feasibility without blasting.

Defining Blastability Assessment for Rock Excavation

Blastability assessment for rock excavation evaluates the suitability of rock formations for controlled explosive fragmentation, focusing on rock type, discontinuities, and in-situ stress conditions. This assessment determines the energy required for effective blasting, optimizing explosive selection and minimizing environmental impacts such as vibration and fly rock. Compared to rippability assessment, which measures ease of mechanical excavation, blastability assessment is crucial for planning efficient and safe rock blasting operations.

Comparative Overview: Rippability vs Blastability

Rippability assessment evaluates the ease of mechanical excavation by measuring soil or rock resistance, using geotechnical parameters such as uniaxial compressive strength and abrasivity, facilitating cost-effective selection of ripping equipment. Blastability assessment determines the suitability for controlled blasting by analyzing rock fracturability, tensile strength, and fracture patterns, optimizing explosive use and minimizing overbreak or damage to adjacent structures. Comparing both methods highlights that rippability is preferred for softer, less consolidated materials, while blastability is essential for hard, massive rock formations requiring precise fragment control.

Key Geological Factors Influencing Rippability

Key geological factors influencing rippability include rock type, strength, and fracturing patterns, which determine how easily the material can be broken down by ripping equipment. Weathering grade and moisture content significantly affect rock cohesion and hardness, impacting the efficiency of ripping operations. Structural features like joints, faults, and bedding planes create planes of weakness that enhance rippability by facilitating mechanical disintegration of the rock mass.

Major Parameters Affecting Blastability

Blastability assessment primarily depends on rock properties such as uniaxial compressive strength, tensile strength, density, and the presence of fractures or joints, which influence how easily the rock can be fragmented by explosives. Rippability assessment, in contrast, centers on parameters like the rock's strength, abrasiveness, and the presence of discontinuities that impact the efficiency of mechanical ripping equipment. Major parameters affecting blastability include rock hardness, fragmentation potential, explosive energy coupling, and the rock mass structure, all critical for optimizing blasting design and ensuring cost-effective excavation.

Field Techniques for Assessing Rippability

Field techniques for assessing rippability primarily involve in-situ methods such as penetrometer tests, seismic refraction surveys, and visual examination of soil and rock formations to evaluate mechanical resistance and layering. These techniques measure parameters like penetration resistance, seismic velocity, and rock hardness, which correlate with the ease of ripping using mechanical equipment, aiding in estimating excavation costs and select appropriate machinery. Unlike blastability assessments that focus on rock fracturing potential via explosive energy, rippability assessments emphasize ground disturbance characteristics relevant to mechanical ripping efficiency.

Laboratory and In-situ Methods in Blastability Evaluation

Rippability assessment primarily employs geotechnical laboratory tests such as uniaxial compressive strength (UCS), point load index, and triaxial shear tests to determine the ease of mechanical excavation, while in-situ methods include seismic refraction and borehole drilling to evaluate rock mass characteristics. Blastability assessment involves laboratory analyses like petrographic examination, strength testing, and fracture toughness measurements to gauge rock fragmentation potential, complemented by field methods such as drillability tests and in-situ explosive energy absorption profiling. Both assessments integrate laboratory and in-situ data to optimize excavation or blasting strategy by accurately characterizing rock behavior under mechanical or explosive forces.

Equipment Selection: Ripping Machines vs Drilling and Blasting Tools

Rippability assessment determines the suitability of ripping machines such as hydraulic excavators and dozers for breaking rock or soil, influencing equipment efficiency and operational cost. Blastability assessment evaluates rock characteristics to optimize drilling and blasting tools, including drill rigs and explosives, ensuring precise fragmentation and controlled energy release. Selecting the appropriate equipment based on these assessments improves productivity, safety, and project timelines in excavation and mining operations.

Economic and Environmental Impacts of Ripping vs Blasting

Rippability assessment determines soil and rock conditions suitable for mechanical ripping, which generally incurs lower operational costs and reduced fuel consumption compared to blasting, leading to significant economic savings. Blastability assessment evaluates the suitability of rock formations for controlled explosions, involving higher upfront expenses for explosives and safety measures, but potentially speeding up excavation in very hard rock conditions. Environmentally, ripping produces less noise, vibration, and air pollution, minimizing ecological disruption, while blasting generates considerable airborne dust, flyrock hazards, and ground vibrations, impacting surrounding ecosystems and communities.

Best Practices for Integrating Rippability and Blastability Assessments

Integrating rippability and blastability assessments requires thorough analysis of geological conditions, including rock hardness, joint spacing, and geotechnical parameters to optimize excavation strategies. Employing geophysical methods and in-situ testing enhances accuracy in delineating material variability, guiding decisions on the most efficient use of ripping and blasting techniques. Coordinating these assessments improves cost-effectiveness and safety by minimizing over-blasting and equipment wear while maximizing productivity in complex rock mass environments.

Rock Mass Rating (RMR)

Rippability assessment relies heavily on Rock Mass Rating (RMR) to evaluate rock excavation feasibility, whereas blastability assessment uses RMR primarily to determine proper explosive design and fragmentation outcomes.

Uniaxial Compressive Strength (UCS)

Uniaxial Compressive Strength (UCS) is a critical parameter in rippability assessment, determining the ease of excavation by ripping, whereas blastability assessment considers UCS alongside rock fracture toughness and fragmentation potential for effective blasting design.

Seismic Velocity (P-wave Velocity)

Seismic P-wave Velocity provides critical quantitative data for differentiating rippability versus blastability by indicating rock strength and fracture potential essential for excavation planning.

Discontinuity Spacing

Discontinuity spacing critically influences rippability assessment by determining rock mass fragmentation potential, whereas blastability assessment evaluates it mainly to optimize explosive energy distribution across discontinuities.

Schmidt Hammer Rebound Value

Schmidt Hammer Rebound Value provides critical quantitative data for Rippability assessment by measuring rock hardness, whereas Blastability assessment requires additional metrics beyond rebound values to evaluate rock fragmentation potential effectively.

Point Load Index

Rippability assessment using the Point Load Index quantifies rock strength to predict excavation ease, while blastability assessment considers additional factors like fracturing and energy absorption for optimizing blasting design.

Rock Quality Designation (RQD)

Rock Quality Designation (RQD) is a critical parameter in rippability assessment that measures the degree of jointing in rock masses, reflecting their fragmentation potential, whereas blastability assessment involves analyzing additional factors such as rock strength and fracture spacing to evaluate the efficiency of drilling and blasting operations.

Geological Strength Index (GSI)

Geological Strength Index (GSI) is a critical parameter in rippability assessment, providing a quantitative measure of rock mass quality that directly influences excavation feasibility, whereas blastability assessment incorporates GSI alongside other dynamic factors to evaluate rock fragmentation potential during blasting.

Joint Orientation

Joint orientation critically influences rippability assessment by determining the ease of mechanical excavation, while in blastability assessment, it affects fragmentation efficiency and blast wave propagation.

Abrasivity Index

Rippability assessment evaluates rock breakability using parameters like the Abrasivity Index to determine excavation ease, while Blastability assessment considers the same index to optimize blasting methods and minimize tool wear.

Rippability assessment vs Blastability assessment Infographic

njnir.com

njnir.com