Molten salt reactors offer enhanced safety through passive cooling and reduced risk of meltdown compared to pebble bed reactors, which rely on continuously circulating fuel pebbles for heat transfer. The chemical stability and high operating temperatures of molten salt enable better fuel efficiency and waste reduction, whereas pebble bed reactors provide modular design advantages and easier refueling during operation. Despite differing approaches, both reactor types contribute to advanced nuclear engineering by improving operational safety, thermal efficiency, and fuel utilization.

Table of Comparison

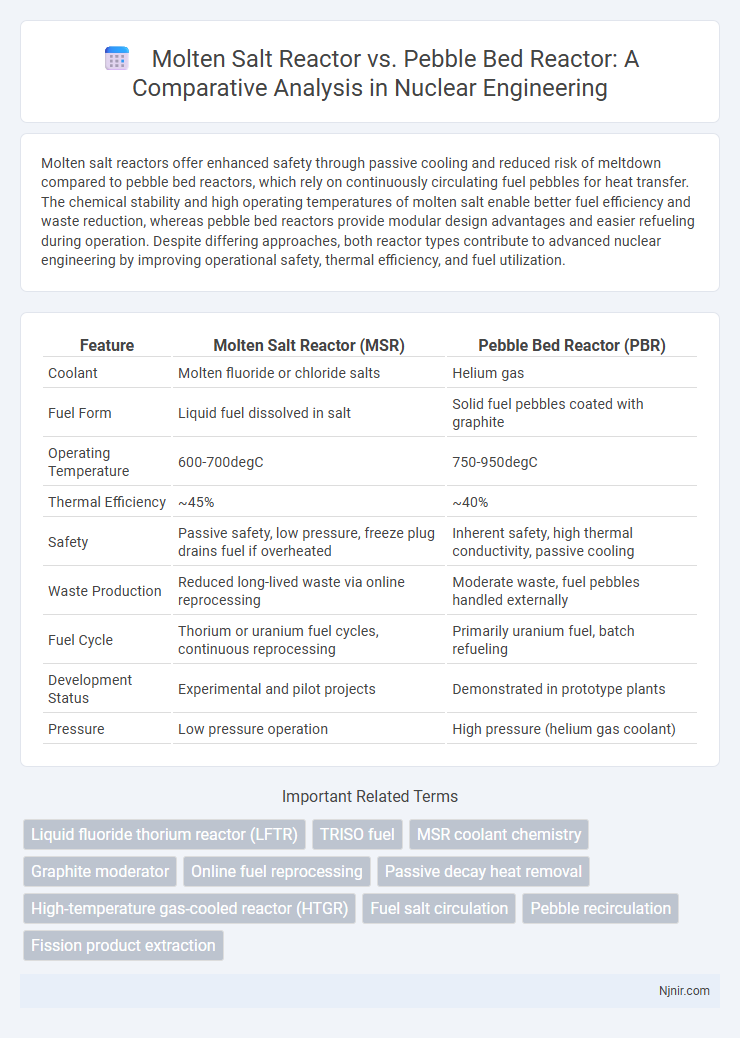

| Feature | Molten Salt Reactor (MSR) | Pebble Bed Reactor (PBR) |

|---|---|---|

| Coolant | Molten fluoride or chloride salts | Helium gas |

| Fuel Form | Liquid fuel dissolved in salt | Solid fuel pebbles coated with graphite |

| Operating Temperature | 600-700degC | 750-950degC |

| Thermal Efficiency | ~45% | ~40% |

| Safety | Passive safety, low pressure, freeze plug drains fuel if overheated | Inherent safety, high thermal conductivity, passive cooling |

| Waste Production | Reduced long-lived waste via online reprocessing | Moderate waste, fuel pebbles handled externally |

| Fuel Cycle | Thorium or uranium fuel cycles, continuous reprocessing | Primarily uranium fuel, batch refueling |

| Development Status | Experimental and pilot projects | Demonstrated in prototype plants |

| Pressure | Low pressure operation | High pressure (helium gas coolant) |

Introduction to Advanced Nuclear Reactor Technologies

Molten salt reactors (MSRs) utilize liquid fuel that circulates through the core, enabling high thermal efficiency and inherent safety features like passive cooling and low operating pressure. Pebble bed reactors (PBRs) use spherical fuel elements coated with ceramic layers, allowing continuous fuel loading and exceptional heat transfer due to the high surface area. Both technologies represent advanced nuclear reactor designs aimed at enhancing safety, fuel utilization, and waste management compared to traditional reactors.

Fundamental Principles of Molten Salt Reactors

Molten Salt Reactors (MSRs) utilize liquid fluoride or chloride salt mixtures as both fuel solvent and coolant, enabling operation at high temperatures and low pressures, which significantly enhances thermal efficiency and safety. These reactors leverage the fundamental principle of circulating fissile material dissolved in molten salt through a reactor core, allowing continuous fuel processing and online refueling, distinguishing them from solid-fuel reactors like Pebble Bed Reactors (PBRs) that use solid graphite spheres with embedded fuel particles. The chemical and physical properties of molten salts provide excellent heat transfer capabilities and radiation resistance, making MSRs a promising technology for sustainable, high-temperature nuclear energy generation.

Core Design and Operation of Pebble Bed Reactors

Pebble bed reactors feature a core design consisting of spherical fuel elements, or pebbles, each encapsulated with ceramic coated particles that provide high structural integrity and fission product retention. The core operates with continuous or batch-wise circulation of pebbles, enabling online fueling and high thermal efficiency due to helium gas coolant flowing through the pebble bed. This design enhances passive safety, modular construction, and simplified heat removal compared to molten salt reactors, which use liquid salt as both fuel solvent and coolant.

Fuel Cycle and Materials Handling

Molten salt reactors (MSRs) utilize liquid fuel that enables continuous online reprocessing and fuel recycling, significantly reducing long-term waste and improving fuel utilization compared to pebble bed reactors (PBRs), which use solid fuel pebbles requiring batch-wise refueling and manual handling. The fuel cycle in MSRs benefits from lower proliferation risks due to in-situ fuel processing, while PBRs face challenges related to the frequent handling and inspection of high-temperature graphite pebbles to manage wear and fission product retention. Material compatibility is critical in MSRs, where corrosion-resistant alloys must withstand aggressive molten salts, contrasting with PBRs that demand robust ceramic-coated fuel particles and high-temperature structural materials to sustain reactor integrity.

Safety Features and Passive Safety Mechanisms

Molten salt reactors (MSRs) enhance safety with passive heat removal through molten salt's high heat capacity and low pressure operation, minimizing risk of pressure-induced accidents. Pebble bed reactors (PBRs) utilize TRISO fuel particles embedded in graphite pebbles, providing exceptional fission product retention and inherent temperature regulation through natural convection. Both designs emphasize passive safety; MSRs achieve rapid draining of molten salt into subcritical configurations during anomalies, while PBRs rely on the high-temperature tolerance of fuel and a negative temperature coefficient to prevent overheating.

Thermodynamic Efficiency and Power Output

Molten salt reactors (MSRs) achieve higher thermodynamic efficiency due to their ability to operate at elevated temperatures, often exceeding 700degC, compared to pebble bed reactors (PBRs) which typically operate around 750degC but face limitations from graphite moderation. MSRs' liquid fuel enables continuous fission product removal, maintaining optimal neutron economy and power output, whereas PBRs rely on solid fuel spheres that limit reactivity control and power density. Consequently, MSRs can deliver greater power output per unit core volume while sustaining improved thermal-to-electric conversion efficiency, enhancing overall plant performance.

Waste Management and Environmental Impact

Molten salt reactors (MSRs) produce less long-lived radioactive waste compared to pebble bed reactors (PBRs) by utilizing liquid fuel that allows for on-site reprocessing and efficient waste reduction. PBRs generate high-quality waste in the form of spent pebbles, which require long-term storage due to their solid fuel composition and slower decay rates. The inherent design of MSRs reduces the potential for environmental contamination through continuous fuel recycling, while PBRs emphasize passive safety but face challenges in managing spent fuel and associated environmental impacts.

Proliferation Resistance and Security Aspects

Molten salt reactors exhibit high proliferation resistance due to their online fuel processing and continuous removal of fission products, minimizing accessibility to weapons-grade materials. Pebble bed reactors offer inherent security advantages with their robust fuel pebbles, which contain TRISO particles providing high containment and resistance to theft or diversion. Both reactor types enhance security through passive safety features, but molten salt reactors have a more complex fuel cycle that further deters proliferation risks.

Economic Considerations and Deployment Scalability

Molten salt reactors offer significant economic advantages due to their potential for continuous fuel reprocessing, reducing fuel costs and waste management expenses, while pebble bed reactors benefit from modular construction that lowers upfront capital investment and accelerates deployment timelines. The scalability of molten salt reactors is enhanced by their flexible operation and ability to utilize various fuel types, promoting adaptability to different grid demands and resource availabilities. Pebble bed reactors excel in incremental capacity expansion, enabling phased investment and risk mitigation, which supports broader market acceptance in developing nuclear infrastructure.

Future Prospects and Research Directions

Molten salt reactors (MSRs) show promising future prospects due to their inherent safety features, high thermal efficiency, and flexibility in fuel cycles, which support the potential for waste reduction and sustainable energy production. Research is increasingly focused on materials development for corrosion resistance, advanced salt chemistry, and online fuel reprocessing technologies to enable continuous operation. Pebble bed reactors (PBRs) emphasize modular design and passive safety with their helium-cooled systems, driving research toward improving fuel pebble integrity, thermal hydraulics optimization, and scalability for deployment in diverse energy markets.

Liquid fluoride thorium reactor (LFTR)

Liquid fluoride thorium reactors (LFTRs), a type of molten salt reactor, offer superior fuel efficiency and inherent safety features compared to pebble bed reactors by utilizing liquid fuel that enables continuous reprocessing and minimizes meltdown risk.

TRISO fuel

Molten salt reactors utilize liquid fuel with dissolved fissile material, enhancing heat transfer and safety, while pebble bed reactors rely on TRISO-coated fuel particles embedded in graphite pebbles, offering robust containment and high-temperature tolerance for improved reactor stability and efficiency.

MSR coolant chemistry

Molten salt reactors use liquid fluoride or chloride salts as coolant and fuel carriers, providing excellent heat transfer and corrosion resistance, while pebble bed reactors rely on helium gas coolant, which offers inertness but lower heat capacity and different chemical stability.

Graphite moderator

Molten salt reactors use graphite moderators dissolved or immersed in liquid fuel for high-temperature stability and neutron economy, while pebble bed reactors employ solid graphite spheres as both fuel containment and moderator to achieve efficient neutron moderation and passive safety.

Online fuel reprocessing

Molten salt reactors enable continuous online fuel reprocessing for efficient waste reduction, while pebble bed reactors require batch offline fuel handling, limiting real-time reprocessing capabilities.

Passive decay heat removal

Molten salt reactors enhance passive decay heat removal through circulating liquid fuel with high heat capacity and low pressure operation, while pebble bed reactors rely on natural convection and ceramic fuel's high thermal conductivity for passive cooling.

High-temperature gas-cooled reactor (HTGR)

The High-Temperature Gas-Cooled Reactor (HTGR) employs helium coolant and graphite moderation to achieve superior thermal efficiency and inherent safety compared to molten salt reactors and pebble bed reactors.

Fuel salt circulation

Molten salt reactors utilize continuous fuel salt circulation for efficient heat transfer and fission product removal, whereas pebble bed reactors rely on fixed solid fuel pebbles with coolant flow around them, limiting direct fuel circulation.

Pebble recirculation

Pebble bed reactors optimize fuel usage and safety through continuous pebble recirculation, enabling real-time removal of spent fuel and improved core performance compared to molten salt reactors.

Fission product extraction

Molten salt reactors enable continuous fission product extraction through liquid fuel processing, enhancing reactor efficiency and safety compared to pebble bed reactors, which require batch-wise solid fuel handling and slower fission product removal.

molten salt reactor vs pebble bed reactor Infographic

njnir.com

njnir.com