MOX fuel, composed of a mixture of plutonium and natural or depleted uranium, offers a higher energy density compared to LEU fuel, enabling more efficient use of nuclear materials. Its utilization helps reduce plutonium stockpiles and enhances fuel cycle sustainability by recycling spent fuel components. However, LEU fuel remains the standard for most reactors due to its proven stability, lower proliferation risk, and established fabrication infrastructure.

Table of Comparison

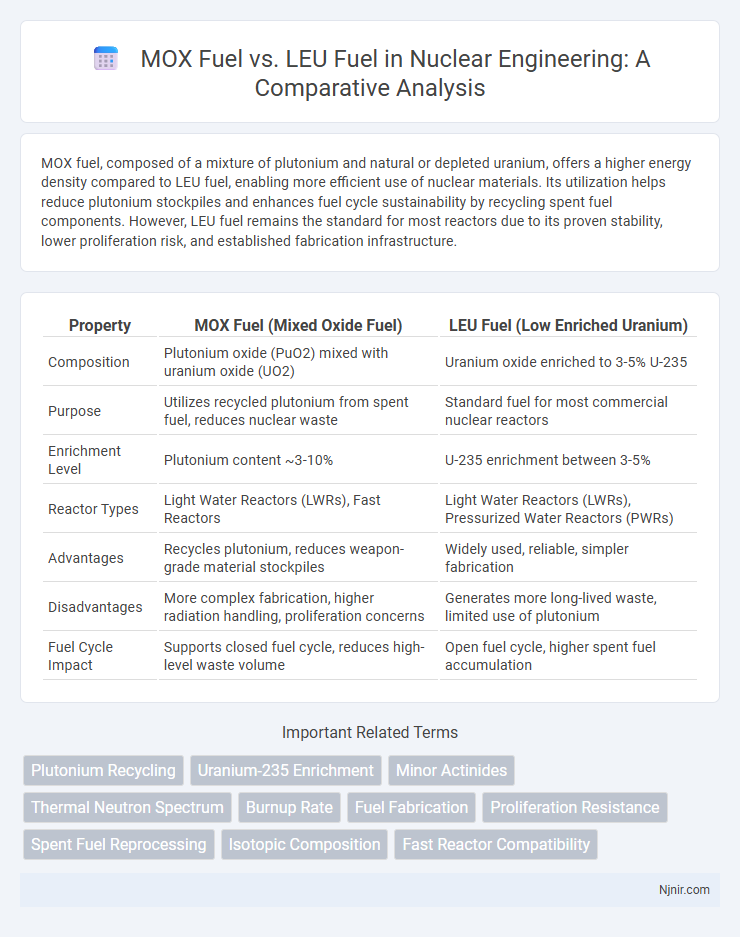

| Property | MOX Fuel (Mixed Oxide Fuel) | LEU Fuel (Low Enriched Uranium) |

|---|---|---|

| Composition | Plutonium oxide (PuO2) mixed with uranium oxide (UO2) | Uranium oxide enriched to 3-5% U-235 |

| Purpose | Utilizes recycled plutonium from spent fuel, reduces nuclear waste | Standard fuel for most commercial nuclear reactors |

| Enrichment Level | Plutonium content ~3-10% | U-235 enrichment between 3-5% |

| Reactor Types | Light Water Reactors (LWRs), Fast Reactors | Light Water Reactors (LWRs), Pressurized Water Reactors (PWRs) |

| Advantages | Recycles plutonium, reduces weapon-grade material stockpiles | Widely used, reliable, simpler fabrication |

| Disadvantages | More complex fabrication, higher radiation handling, proliferation concerns | Generates more long-lived waste, limited use of plutonium |

| Fuel Cycle Impact | Supports closed fuel cycle, reduces high-level waste volume | Open fuel cycle, higher spent fuel accumulation |

Introduction to MOX Fuel and LEU Fuel

MOX fuel, or Mixed Oxide fuel, combines plutonium and natural or depleted uranium to utilize recycled nuclear materials, enhancing fuel sustainability and reducing plutonium stockpiles. LEU fuel, or Low Enriched Uranium, contains uranium enriched to 3-5% U-235, serving as the standard fuel in most nuclear reactors due to its balance of efficiency and proliferation resistance. Both fuel types play crucial roles in nuclear energy production, with MOX offering a recycling option and LEU providing stable reactor performance.

Composition and Fabrication Processes

MOX fuel, composed primarily of plutonium oxide blended with depleted or natural uranium oxide, contrasts with LEU fuel, which consists mainly of uranium enriched to 3-5% U-235. The fabrication of MOX fuel involves handling radioactive plutonium powders in glove boxes under stringent radiological controls, utilizing pelletizing and sintering processes similar to LEU but with enhanced containment measures. LEU fuel fabrication focuses on uranium conversion, enrichment, and pellet manufacturing with well-established industrial-scale processes optimized for uniformity and cost-effectiveness.

Nuclear Reactions and Fission Characteristics

MOX fuel, composed of a blend of plutonium and uranium oxides, exhibits a higher neutron spectrum and increased fission cross-sections for plutonium isotopes compared to LEU fuel, which primarily contains uranium-235. The presence of plutonium-239 in MOX fuel enables a more sustained chain reaction due to its higher probability of fission when interacting with thermal neutrons, altering neutron flux and reactivity coefficients. LEU fuel relies on the fissile uranium-235 isotope, resulting in different neutron economy and fission product generation, influencing reactor control and fuel cycle parameters.

Advantages of MOX Fuel

MOX fuel, made by blending plutonium with depleted uranium, offers substantial advantages over Low-Enriched Uranium (LEU) fuel by enabling the recycling of surplus plutonium from spent nuclear fuel and weapons stockpiles, reducing nuclear waste and enhancing resource utilization. MOX fuel provides higher fuel burnup and increased reactor efficiency, leading to longer fuel cycles and reduced fuel fabrication frequency. Its use also supports non-proliferation goals by decreasing the availability of separated plutonium for weapons production.

Advantages of LEU Fuel

LEU fuel, containing less than 20% enrichment of uranium-235, offers enhanced proliferation resistance and improved nuclear safety compared to MOX fuel, which contains plutonium. The widespread availability and established supply chain of LEU fuel make it a more economically viable and reliable option for commercial reactors. Furthermore, LEU fuel generates less long-lived radioactive waste, simplifying waste management and reducing environmental impact.

Safety Considerations and Challenges

MOX fuel, containing a mixture of plutonium and uranium, presents unique safety challenges including higher radiotoxicity and increased risks of criticality accidents compared to LEU fuel, which primarily consists of low-enriched uranium with lower fissile content. Handling MOX requires stringent safety protocols due to its greater heat generation and neutron emission, necessitating enhanced shielding and containment measures in reactor operations. LEU fuel benefits from established safety frameworks and lower proliferation risks, while MOX's use demands advanced monitoring to mitigate potential chemical toxicity and radiological hazards during fabrication, transportation, and disposal.

Reactor Compatibility and Performance

MOX fuel, composed of mixed oxides of plutonium and uranium, is compatible with many light-water reactors designed for low-enriched uranium (LEU) fuel but often requires specific reactor modifications to accommodate its higher neutron flux and different reactivity characteristics. Performance-wise, MOX fuel can achieve higher burnup rates and effectively utilize plutonium from spent fuel, enhancing fuel sustainability and reducing nuclear waste. LEU fuel maintains stable reactor operation with predictable neutronic behavior, making it the standard choice for most commercial reactors due to its established safety and regulatory framework.

Waste Management and Environmental Impacts

MOX fuel, made from recycled plutonium and uranium, reduces long-term radioactive waste by reusing fissile materials and decreasing the volume of high-level spent fuel compared to LEU fuel, which relies solely on enriched uranium. However, MOX fuel handling and fabrication pose greater radiological risks and require stringent safeguards due to plutonium's toxicity and proliferation concerns. LEU fuel produces more volume of spent fuel, resulting in higher repository space demands and longer-term environmental impacts from uranium mining and enrichment processes.

Economic and Supply Chain Factors

MOX fuel, synthesized from plutonium and depleted uranium, offers economic advantages by recycling nuclear waste and reducing reliance on enriched uranium, potentially lowering fuel costs compared to LEU fuel. The supply chain for MOX fuel is more complex due to stringent security measures and limited reprocessing facilities, which can increase lead times and logistical expenses relative to the more established LEU fuel cycle. LEU fuel benefits from a well-developed global supply chain with widespread enrichment capabilities, ensuring more stable pricing and reliable availability despite higher raw material consumption.

Future Prospects and Research Directions

MOX fuel, composed of mixed oxides of plutonium and uranium, offers promising future prospects for recycling plutonium from spent nuclear fuel and reducing nuclear waste volume. Research focuses on enhancing MOX fuel's irradiation performance, improving fabrication methods, and developing advanced reactors optimized for MOX use to maximize resource efficiency and proliferation resistance. LEU fuel continues to advance with novel fuel cladding materials and higher burnup capabilities, supporting safer, longer-lasting fuel cycles while integrating with emerging small modular reactor designs.

Plutonium Recycling

MOX fuel enables effective recycling of plutonium from spent nuclear fuel, reducing plutonium stockpiles and enhancing sustainability compared to LEU fuel, which does not recycle plutonium.

Uranium-235 Enrichment

MOX fuel contains recycled plutonium with lower Uranium-235 enrichment levels compared to LEU fuel, which typically has Uranium-235 enriched between 3% and 5% for use in commercial reactors.

Minor Actinides

MOX fuel contains higher concentrations of Minor Actinides than LEU fuel, enhancing waste transmutation and reducing long-term radiotoxicity in nuclear reactors.

Thermal Neutron Spectrum

MOX fuel, containing plutonium-239 and uranium-238, exhibits a different neutron absorption and fission behavior in the thermal neutron spectrum compared to LEU fuel, which primarily relies on uranium-235 for sustaining reactions.

Burnup Rate

MOX fuel typically achieves a higher burnup rate than LEU fuel, enhancing fuel efficiency and reducing nuclear waste generation.

Fuel Fabrication

MOX fuel fabrication involves blending plutonium dioxide with uranium dioxide, requiring specialized glovebox handling for radiological safety, while LEU fuel fabrication uses low-enriched uranium powder processed in conventional facilities with standard industrial controls.

Proliferation Resistance

MOX fuel demonstrates higher proliferation resistance than LEU fuel by incorporating plutonium in a form less suitable for weaponization, thereby reducing risks associated with nuclear material diversion.

Spent Fuel Reprocessing

Spent fuel reprocessing of MOX fuel recovers valuable plutonium and uranium isotopes for reuse, offering higher resource efficiency compared to LEU fuel reprocessing which primarily focuses on uranium recovery.

Isotopic Composition

MOX fuel contains a mix of plutonium isotopes (primarily Pu-239 and Pu-241) alongside uranium isotopes, whereas LEU fuel mainly consists of uranium isotopes with a high concentration of U-235.

Fast Reactor Compatibility

MOX fuel demonstrates superior fast reactor compatibility due to its higher plutonium content, which enables better neutron economy and enhanced breeding capabilities compared to LEU fuel.

MOX fuel vs LEU fuel Infographic

njnir.com

njnir.com