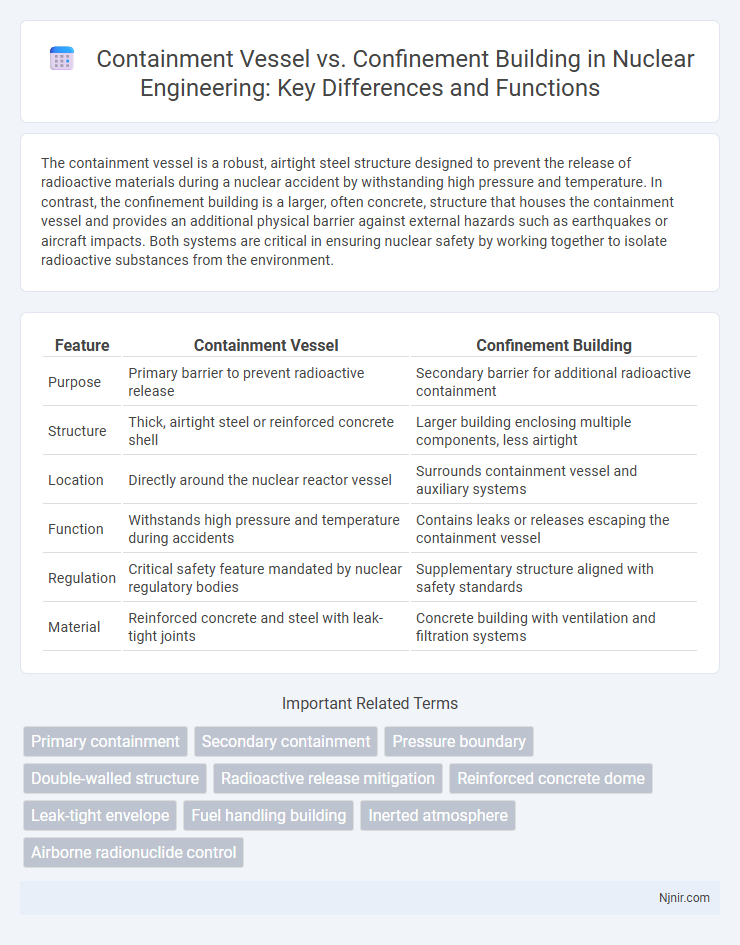

The containment vessel is a robust, airtight steel structure designed to prevent the release of radioactive materials during a nuclear accident by withstanding high pressure and temperature. In contrast, the confinement building is a larger, often concrete, structure that houses the containment vessel and provides an additional physical barrier against external hazards such as earthquakes or aircraft impacts. Both systems are critical in ensuring nuclear safety by working together to isolate radioactive substances from the environment.

Table of Comparison

| Feature | Containment Vessel | Confinement Building |

|---|---|---|

| Purpose | Primary barrier to prevent radioactive release | Secondary barrier for additional radioactive containment |

| Structure | Thick, airtight steel or reinforced concrete shell | Larger building enclosing multiple components, less airtight |

| Location | Directly around the nuclear reactor vessel | Surrounds containment vessel and auxiliary systems |

| Function | Withstands high pressure and temperature during accidents | Contains leaks or releases escaping the containment vessel |

| Regulation | Critical safety feature mandated by nuclear regulatory bodies | Supplementary structure aligned with safety standards |

| Material | Reinforced concrete and steel with leak-tight joints | Concrete building with ventilation and filtration systems |

Introduction to Nuclear Safety Structures

Containment vessels are robust, airtight structures designed to prevent the release of radioactive materials from a nuclear reactor during an accident, serving as the final barrier in nuclear safety. Confinement buildings provide an additional layer of protection by enclosing systems that handle radioactive substances, mitigating the spread of contamination within the facility. Both structures are critical components in nuclear safety engineering, ensuring environmental and human protection by limiting radiological hazards.

Defining Containment Vessels in Nuclear Engineering

Containment vessels in nuclear engineering are robust, airtight structures designed to prevent the release of radioactive materials during normal operations and accident scenarios, specifically housing the reactor core and primary cooling system. These vessels are typically constructed from thick steel or reinforced concrete to withstand high pressure, temperature, and radiation levels. Confinement buildings serve as an additional protective barrier surrounding the containment vessel, providing environmental protection and secondary containment, but the containment vessel itself is the critical first line of defense in nuclear safety systems.

Understanding Confinement Buildings

Confinement buildings serve as critical safety structures designed to contain radioactive materials and prevent their release into the environment during nuclear incidents. Unlike containment vessels, which are typically robust, steel-reinforced structures directly enclosing the reactor, confinement buildings encompass a larger area, providing multiple layers of protection such as concrete walls, ventilation filters, and controlled access points. Understanding confinement buildings involves recognizing their role in mitigating radioactive contamination through engineered barriers and pressure control systems, essential for nuclear power plant safety.

Core Functions: Containment Vessel vs Confinement Building

The containment vessel serves as a robust, steel-reinforced barrier designed to prevent the release of radioactive materials during a nuclear incident by tightly enclosing the reactor core. The confinement building functions as an additional protective shell, often constructed from concrete, that surrounds and supports the containment vessel while managing pressure and filtering airborne contaminants. Both structures work synergistically to control radiation exposure, maintain structural integrity under extreme conditions, and ensure environmental safety.

Structural Design Differences

Containment vessels are typically steel-reinforced, pressure-resistant structures designed to withstand high internal pressures from reactor accidents, ensuring airtight isolation of radioactive materials. Confinement buildings incorporate multiple layers of steel and concrete, emphasizing robust physical barriers with significant thermal insulation and shock absorption to protect against external impacts and contain radioactive dust or gases. Structural design differences center on the containment vessel's focus on airtight, pressure-tight integrity versus the confinement building's broader role in shielding and environmental containment with more extensive spatial volume.

Material Selection and Integrity

Containment vessels utilize thick reinforced concrete and steel alloys such as carbon steel and stainless steel to withstand high pressure and radiation, prioritizing mechanical strength and leak-tightness. Confinement buildings incorporate lighter steel frameworks combined with fire-resistant materials like gypsum board, focusing on preventing the release of radioactive materials under normal or accident conditions. Material integrity in containment vessels is maintained through rigorous testing and corrosion-resistant coatings, while confinement buildings emphasize durability against environmental factors and ease of inspection and maintenance.

Regulatory Standards and Compliance

Containment vessels and confinement buildings are critical components in nuclear safety, each subject to stringent regulatory standards such as those established by the U.S. Nuclear Regulatory Commission (NRC) and the International Atomic Energy Agency (IAEA). Containment vessels must comply with regulations addressing pressure resistance, leak-tightness, and radiation shielding to prevent radioactive releases during accidents, while confinement buildings focus on controlling contamination and providing an additional safety barrier. Both structures are evaluated through rigorous testing, inspection, and certification processes to ensure adherence to safety margins defined in standards like NRC Regulatory Guide 1.52 and IAEA Safety Standards Series No. SSG-2.

Performance in Accident Scenarios

Containment vessels are engineered to provide a robust, pressure-resistant barrier to prevent the release of radioactive materials during severe accident scenarios, ensuring structural integrity under high stress and elevated temperatures. Confinement buildings serve as an additional layer by enclosing multiple safety systems and mitigating the spread of contamination in the event of leaks or failures within the containment vessel. The performance of containment vessels is critical for immediate accident response, while confinement buildings contribute to long-term containment and environmental protection.

Operational and Maintenance Considerations

Containment vessels are designed with robust, tightly sealed steel or concrete structures to provide direct leak-tight barriers for radioactive material, requiring specialized inspection and maintenance to prevent corrosion and ensure structural integrity under high pressure. Confinement buildings offer a larger, ventilated space with filtered air exhaust systems to control the release of contaminants, focusing maintenance on ventilation system reliability and filter replacement schedules. Operationally, containment vessels demand continuous monitoring of pressure and temperature conditions, while confinement buildings emphasize airflow management and emergency ventilation protocols to maintain safe environmental conditions.

Future Trends in Nuclear Safety Architecture

Future trends in nuclear safety architecture emphasize advanced containment vessels with enhanced multi-layered steel-reinforced concrete designed to withstand extreme external events and internal accidents. Confinement buildings are evolving to integrate passive safety systems that reduce reliance on active controls and human intervention, improving long-term disaster resilience. Innovations in material science and real-time structural health monitoring are driving the development of next-generation containment solutions to ensure higher integrity and containment efficiency in nuclear power plants.

Primary containment

The containment vessel serves as the primary containment barrier designed to prevent the release of radioactive materials from a nuclear reactor core, while the confinement building provides secondary containment that encloses the containment vessel and controls the environment to mitigate the spread of radioactive contaminants during an incident.

Secondary containment

The secondary containment in nuclear facilities primarily refers to the confinement building, which acts as an additional protective barrier surrounding the primary containment vessel to prevent the release of radioactive materials.

Pressure boundary

The containment vessel serves as the primary pressure boundary designed to withstand high internal pressures, while the confinement building acts as a secondary barrier primarily for airborne radioactive material containment.

Double-walled structure

A containment vessel features a robust double-walled structure designed to prevent radioactive leaks, whereas a confinement building uses a single-wall system primarily for filtration and controlled ventilation.

Radioactive release mitigation

Containment vessels provide a robust, airtight barrier directly surrounding the reactor core to prevent radioactive release during accidents, whereas confinement buildings serve as an additional, larger structure designed to reduce the spread of radioactivity into the environment by containing any leaked contaminants from the containment vessel.

Reinforced concrete dome

The reinforced concrete dome of a containment vessel provides a robust, airtight barrier designed to withstand internal pressure and prevent the release of radioactive materials, whereas the confinement building serves as an additional protective structure to shield against external impacts and environmental hazards.

Leak-tight envelope

The containment vessel is a highly leak-tight, robust metal structure designed to prevent radioactive releases, while the confinement building is a larger, less leak-tight enclosure that provides secondary containment and houses the containment vessel.

Fuel handling building

The fuel handling building is typically housed within the confinement building rather than the containment vessel, providing an additional barrier for controlling radioactive material during fuel transfer and maintenance operations.

Inerted atmosphere

Containment vessels maintain an inerted atmosphere to prevent combustion of hydrogen or other flammable gases within nuclear reactors, whereas confinement buildings provide a physical barrier without necessarily controlling the internal atmosphere.

Airborne radionuclide control

Containment vessels provide a robust, airtight barrier specifically designed to prevent the release of airborne radionuclides during a nuclear accident, while confinement buildings offer an additional large-scale structural enclosure that reduces radionuclide dispersion but typically rely on ventilation and filtration systems for airborne radionuclide control.

containment vessel vs confinement building Infographic

njnir.com

njnir.com