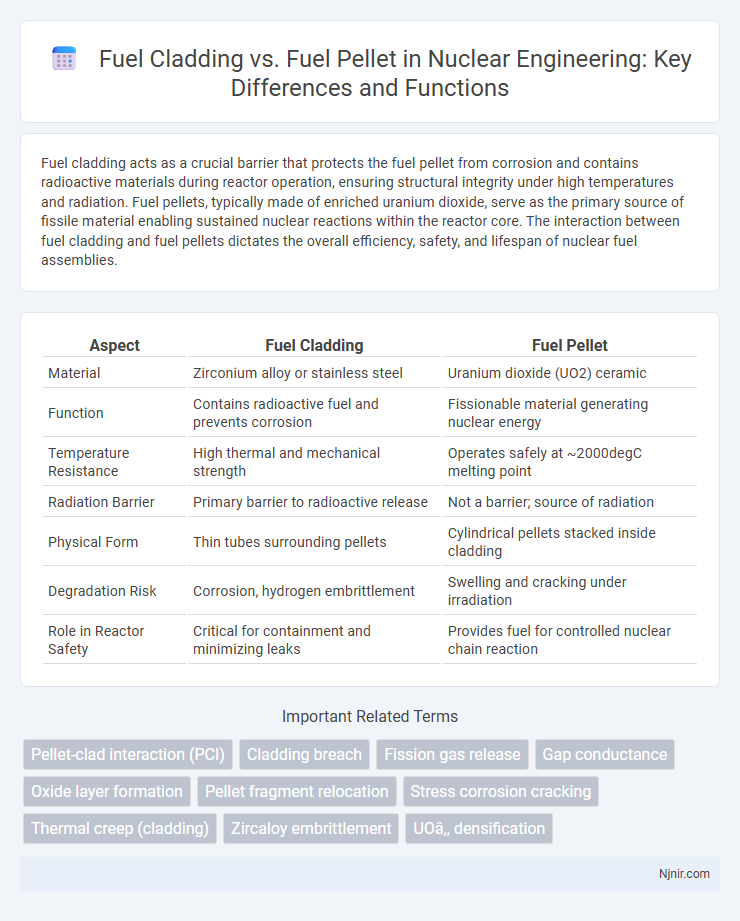

Fuel cladding acts as a crucial barrier that protects the fuel pellet from corrosion and contains radioactive materials during reactor operation, ensuring structural integrity under high temperatures and radiation. Fuel pellets, typically made of enriched uranium dioxide, serve as the primary source of fissile material enabling sustained nuclear reactions within the reactor core. The interaction between fuel cladding and fuel pellets dictates the overall efficiency, safety, and lifespan of nuclear fuel assemblies.

Table of Comparison

| Aspect | Fuel Cladding | Fuel Pellet |

|---|---|---|

| Material | Zirconium alloy or stainless steel | Uranium dioxide (UO2) ceramic |

| Function | Contains radioactive fuel and prevents corrosion | Fissionable material generating nuclear energy |

| Temperature Resistance | High thermal and mechanical strength | Operates safely at ~2000degC melting point |

| Radiation Barrier | Primary barrier to radioactive release | Not a barrier; source of radiation |

| Physical Form | Thin tubes surrounding pellets | Cylindrical pellets stacked inside cladding |

| Degradation Risk | Corrosion, hydrogen embrittlement | Swelling and cracking under irradiation |

| Role in Reactor Safety | Critical for containment and minimizing leaks | Provides fuel for controlled nuclear chain reaction |

Introduction to Nuclear Fuel Components

Fuel cladding serves as a critical barrier, encasing nuclear fuel pellets to contain fission products and prevent radioactive contamination while maintaining structural integrity under high temperatures and radiation. Nuclear fuel pellets, typically made of enriched uranium dioxide (UO2), are densely packed cylindrical shapes designed to undergo fission reactions efficiently within the reactor core. The interaction between fuel pellets and their cladding ensures safe and effective energy generation in nuclear reactors by facilitating heat transfer and protecting the environment from radioactive materials.

Overview of Fuel Cladding and Fuel Pellets

Fuel cladding is a critical protective layer, typically made from zirconium alloys, that encases nuclear fuel pellets to prevent radioactive fission products from escaping into the reactor coolant. Fuel pellets, composed primarily of enriched uranium dioxide (UO2), serve as the fissile material generating heat through nuclear fission reactions. Together, the integrity of fuel cladding and the efficiency of fuel pellets directly influence reactor safety, performance, and fuel cycle economics.

Material Composition: Cladding vs. Pellet

Fuel cladding primarily consists of zirconium alloys due to their low neutron absorption and excellent corrosion resistance under reactor conditions. Fuel pellets are typically made from enriched uranium dioxide (UO2), offering high density and thermal conductivity essential for efficient fission reactions. The contrasting materials ensure structural integrity and efficient nuclear fuel performance within the reactor core.

Manufacturing Processes

Fuel cladding manufacturing involves precision metallurgical processes such as extrusion, pilgering, and stress-relief annealing to ensure corrosion resistance and mechanical integrity under high temperatures and radiation. Fuel pellet manufacturing centers on powder metallurgy techniques including powder blending, pressing, and sintering to produce dense, uniform uranium dioxide pellets with optimal thermal conductivity. Both processes demand strict quality control and materials compatibility to maintain safety and efficiency in nuclear reactors.

Functional Roles in Reactor Operation

Fuel cladding serves as the primary barrier preventing the release of radioactive fission products from fuel pellets into the reactor coolant, ensuring safe containment during reactor operation. Fuel pellets, composed of enriched uranium dioxide (UO2), function as the actual fuel source where nuclear fission occurs, generating thermal energy essential for power production. The interaction between fuel pellet integrity and cladding corrosion resistance directly impacts the reactor's operational efficiency and safety margins.

Thermal Performance Comparison

Fuel cladding acts as a protective barrier surrounding fuel pellets, influencing thermal conductivity and heat transfer efficiency within a nuclear reactor. Fuel pellets, typically made from enriched uranium dioxide, exhibit high thermal conductivity essential for efficient heat generation, while cladding materials like zirconium alloys provide structural integrity and moderate thermal resistance essential for safe reactor operation. The thermal performance comparison highlights that while fuel pellets are optimized for maximum heat output, the cladding's thermal conductivity and thickness critically affect overall temperature gradients and reactor safety margins.

Mechanical Properties and Behavior

Fuel cladding exhibits high mechanical strength and corrosion resistance, essential for maintaining integrity under reactor operating conditions and preventing radioactive release. Fuel pellets, typically uranium dioxide, possess brittle mechanical behavior with limited ductility, requiring precise design to accommodate thermal expansion without cracking. The synergistic interaction between the ductile cladding and brittle fuel pellet governs overall fuel performance and safety during irradiation cycles.

Corrosion and Radiation Resistance

Fuel cladding acts as a critical barrier, providing superior corrosion resistance by preventing direct contact between the nuclear fuel pellet and the reactor coolant, which minimizes material degradation and enhances long-term structural integrity. Fuel pellets, typically made of uranium dioxide, exhibit high radiation resistance due to their ceramic nature, maintaining stability at elevated temperatures and under intense neutron flux. The synergy between corrosion-resistant cladding materials such as zirconium alloys and radiation-resistant fuel pellets ensures efficient containment of radioactive fission products and extends fuel cycle lifespan in nuclear reactors.

Safety Implications and Failure Modes

Fuel cladding acts as the primary barrier preventing radioactive materials from escaping the fuel pellet, significantly affecting nuclear reactor safety. Failure modes for cladding include corrosion, embrittlement, and thermal stress, which can lead to breaches and release of fission products, while pellet failure often involves cracking due to thermal expansion and swelling. Understanding these failure mechanisms is critical for preventing radioactive contamination and ensuring the structural integrity of the nuclear fuel during operation.

Recent Innovations and Future Trends

Recent innovations in fuel cladding explore advanced materials like silicon carbide composites and oxide dispersion-strengthened steels to enhance corrosion resistance and accident tolerance in nuclear reactors. Fuel pellet development emphasizes high-density uranium dioxide and accident-tolerant fuels incorporating additives such as chromium or gadolinium to improve thermal conductivity and reduce fission gas release. Future trends suggest integrated designs combining improved cladding and pellet materials to optimize fuel performance, safety margins, and economic efficiency in next-generation nuclear reactors.

Pellet-clad interaction (PCI)

Pellet-clad interaction (PCI) refers to the mechanical and chemical stresses between nuclear fuel pellets and cladding, causing cladding deformation and potential failure during reactor operation.

Cladding breach

Fuel cladding breach compromises the containment of nuclear fuel pellets, leading to potential radioactive release and reduced reactor safety.

Fission gas release

Fuel cladding acts as a barrier preventing the release of fission gases generated within fuel pellets during nuclear reactions.

Gap conductance

Fuel cladding thermal performance directly depends on gap conductance, which critically influences heat transfer efficiency between the fuel pellet and cladding in nuclear reactors.

Oxide layer formation

Fuel cladding forms a protective oxide layer that prevents fuel pellet oxidation and maintains reactor integrity during operation.

Pellet fragment relocation

Fuel pellet fragment relocation significantly affects fuel cladding integrity by increasing the risk of localized stress corrosion and compromising the cladding's mechanical stability during reactor operation.

Stress corrosion cracking

Fuel cladding is more susceptible to stress corrosion cracking due to its exposure to high-temperature coolant environments, while fuel pellets primarily face mechanical stress and thermal expansion challenges inside the cladding.

Thermal creep (cladding)

Fuel cladding experiences thermal creep, a temperature-induced deformation critical for maintaining structural integrity under high reactor temperatures, whereas fuel pellets primarily govern fission heat generation without significant creep concerns.

Zircaloy embrittlement

Zircaloy embrittlement in nuclear reactors primarily affects fuel cladding, compromising its mechanical integrity and safety, whereas fuel pellets composed of uranium dioxide are less susceptible to such degradation.

UO₂ densification

UO2 fuel pellet densification significantly impacts fuel cladding integrity by reducing pellet swelling and minimizing mechanical stress on the cladding during reactor operation.

Fuel Cladding vs Fuel Pellet Infographic

njnir.com

njnir.com