Vitrification immobilizes high-level radioactive waste by incorporating it into a stable glass matrix, effectively reducing its leachability and long-term environmental impact. Dry cask storage involves sealing spent nuclear fuel in robust, air-cooled steel and concrete containers, providing secure interim containment with ease of transport and monitoring. Both methods enhance nuclear waste management, but vitrification offers superior chemical stabilization, while dry cask storage emphasizes operational flexibility and retrievability.

Table of Comparison

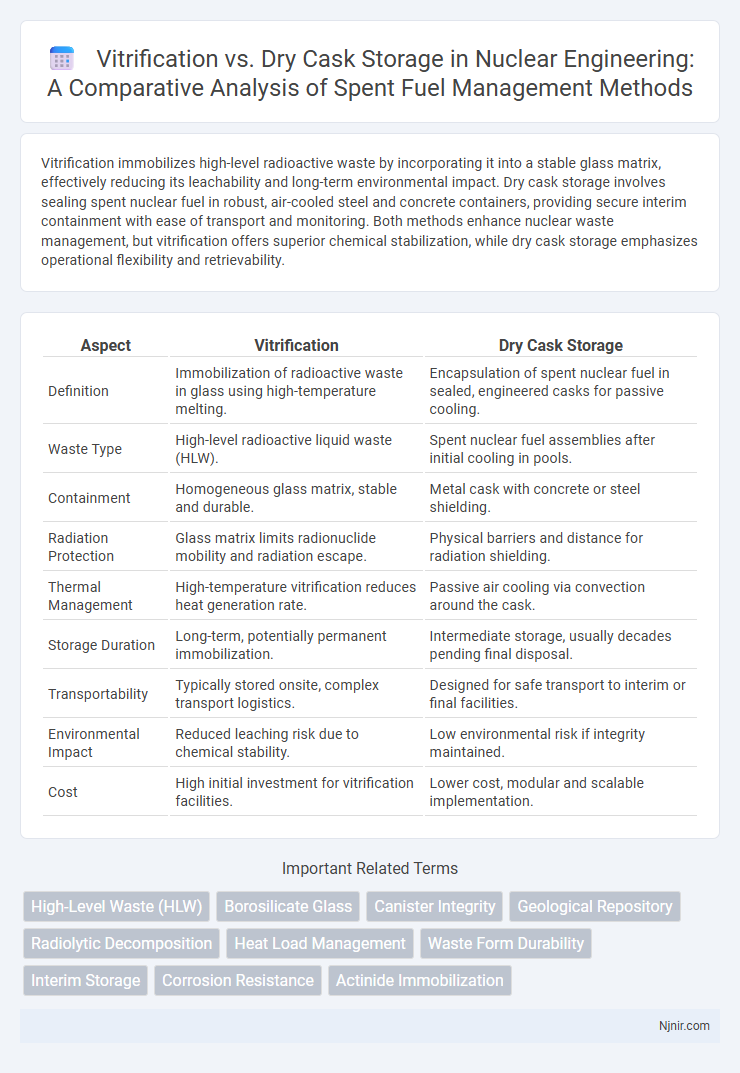

| Aspect | Vitrification | Dry Cask Storage |

|---|---|---|

| Definition | Immobilization of radioactive waste in glass using high-temperature melting. | Encapsulation of spent nuclear fuel in sealed, engineered casks for passive cooling. |

| Waste Type | High-level radioactive liquid waste (HLW). | Spent nuclear fuel assemblies after initial cooling in pools. |

| Containment | Homogeneous glass matrix, stable and durable. | Metal cask with concrete or steel shielding. |

| Radiation Protection | Glass matrix limits radionuclide mobility and radiation escape. | Physical barriers and distance for radiation shielding. |

| Thermal Management | High-temperature vitrification reduces heat generation rate. | Passive air cooling via convection around the cask. |

| Storage Duration | Long-term, potentially permanent immobilization. | Intermediate storage, usually decades pending final disposal. |

| Transportability | Typically stored onsite, complex transport logistics. | Designed for safe transport to interim or final facilities. |

| Environmental Impact | Reduced leaching risk due to chemical stability. | Low environmental risk if integrity maintained. |

| Cost | High initial investment for vitrification facilities. | Lower cost, modular and scalable implementation. |

Introduction to Nuclear Waste Management

Vitrification immobilizes high-level nuclear waste by incorporating it into durable glass, enhancing long-term stability and reducing environmental contamination risks. Dry cask storage involves sealing spent nuclear fuel in robust steel and concrete containers, providing secure, passive cooling and shielding from radiation. Both methods play crucial roles in nuclear waste management strategies by ensuring safe containment and minimizing hazards during storage and disposal.

Overview of Vitrification Technology

Vitrification technology involves converting radioactive waste into stable glass by melting it with additives to immobilize hazardous elements and prevent environmental contamination. This method ensures long-term durability and resistance to leaching, making it a preferred solution for high-level radioactive waste management. Compared to dry cask storage, vitrification provides a permanent, immobilized waste form that reduces the risk of radionuclide release over time.

Fundamentals of Dry Cask Storage

Dry cask storage involves sealing spent nuclear fuel in airtight containers made of steel and concrete, providing robust radiation shielding and passive cooling through natural air circulation. This method offers a secure, long-term storage solution that avoids the complexities of liquid-based immobilization processes like vitrification. The fundamental advantage lies in its simplicity, safety, and cost-effectiveness, enabling containment of radioactive materials without requiring extensive chemical treatment.

Comparative Safety and Containment Performance

Vitrification provides superior immobilization of high-level radioactive waste by converting it into a stable glass matrix, minimizing the risk of radionuclide release compared to dry cask storage, which relies on robust metal and concrete barriers to contain spent nuclear fuel. Dry cask storage offers effective heat dissipation and physical protection but is susceptible to potential corrosion and mechanical degradation over extended periods, whereas vitrified waste forms exhibit long-term chemical durability and resistance to leaching. Safety assessments indicate vitrification is optimal for permanent disposal, while dry cask storage serves as a safer interim solution with proven containment performance under normal and accident conditions.

Long-Term Environmental Impact

Vitrification immobilizes radioactive waste in a stable glass matrix, significantly reducing leachability and preventing groundwater contamination over millennia. Dry cask storage involves sealed steel and concrete containers that provide robust shielding but require ongoing monitoring to mitigate risks of corrosion and potential radioactive leakage. Long-term environmental safety favors vitrification for permanent waste isolation, while dry casks serve as interim solutions pending final repository development.

Economic Analysis: Costs and Resource Allocation

Vitrification involves high upfront costs due to complex industrial processes and specialized materials but offers long-term stability and reduced waste volume, optimizing resource allocation over time. Dry cask storage requires lower initial investment with modular scalability, enabling flexible deployment and lower maintenance expenses, but may incur higher cumulative costs over extended storage periods. Economic analysis must weigh capital expenditure, operational costs, and lifecycle management to determine cost-effectiveness based on storage duration and environmental safety requirements.

Challenges in Implementation and Operation

Vitrification presents challenges such as the need for high-temperature processing equipment and managing the stability of molten glass to immobilize radioactive waste effectively. Dry cask storage faces operational difficulties including ensuring long-term structural integrity of casks and maintaining adequate cooling without active systems. Both methods require stringent regulatory compliance and robust monitoring to mitigate risks associated with radiation containment and environmental factors.

Regulatory and Compliance Considerations

Regulatory frameworks for vitrification emphasize strict controls on glass composition to ensure long-term durability and containment of high-level radioactive waste, often guided by agencies like the U.S. Nuclear Regulatory Commission (NRC) and the International Atomic Energy Agency (IAEA). Dry cask storage regulations focus on robust structural standards, thermal performance, and radiation shielding, with requirements for periodic inspections and monitoring to maintain safety and prevent environmental contamination. Both methods must comply with national and international waste management policies, but vitrification demands more rigorous material verification, while dry cask storage prioritizes physical security and operational compliance over extended storage durations.

Innovations and Future Trends

Vitrification involves converting high-level radioactive waste into stable glass logs, enhancing safety and durability, while dry cask storage uses robust steel and concrete containers for interim containment of spent nuclear fuel. Innovations in vitrification include advanced melter technologies and improved glass formulations that increase waste loading capacity and thermal stability, significantly reducing long-term environmental risks. Future trends emphasize integrating real-time monitoring systems for dry casks and developing hybrid storage solutions combining vitrified waste and cask technologies to optimize nuclear waste management efficiency and security.

Conclusion: Selecting Optimal Nuclear Waste Strategies

Selecting optimal nuclear waste strategies involves balancing long-term safety, environmental impact, and cost-efficiency between vitrification and dry cask storage. Vitrification provides enhanced containment by immobilizing waste in glass, significantly reducing leachability and radiation release over millennia. Dry cask storage offers flexibility and lower immediate costs but requires ongoing monitoring and maintenance to manage potential risks of corrosion and radiation leakage.

High-Level Waste (HLW)

Vitrification immobilizes High-Level Waste (HLW) in glass logs for enhanced containment and long-term stability, while dry cask storage secures HLW in heavy steel and concrete containers designed for temporary on-site cooling and radiation shielding.

Borosilicate Glass

Borosilicate glass in vitrification securely immobilizes high-level radioactive waste, offering superior chemical durability and resistance to radiation compared to dry cask storage's metal and concrete containment.

Canister Integrity

Vitrification ensures superior canister integrity by immobilizing radioactive waste in glass, preventing corrosion and leakage, whereas dry cask storage relies on metal canisters prone to degradation over time under environmental stress.

Geological Repository

Geological repositories provide long-term isolation for high-level nuclear waste by utilizing vitrification to immobilize radioactive materials in glass, while dry cask storage offers interim containment but relies on engineered barriers rather than geological stability.

Radiolytic Decomposition

Vitrification significantly reduces radiolytic decomposition by immobilizing radioactive waste in a stable glass matrix, whereas dry cask storage exposes materials to higher radiolytic effects due to gaseous phase interactions.

Heat Load Management

Vitrification efficiently immobilizes high-level radioactive waste with minimal heat generation, whereas dry cask storage manages higher heat loads through passive air cooling systems to ensure safe thermal dissipation.

Waste Form Durability

Vitrification produces a highly durable, stable glass waste form resistant to leaching and radiation damage, whereas dry cask storage relies on robust metal and concrete containment that primarily safeguards against environmental exposure but offers less intrinsic waste form durability.

Interim Storage

Interim storage using dry cask systems provides a safer, more cost-effective, and flexible solution for containing high-level radioactive waste compared to vitrification, which immobilizes waste in glass but is primarily suited for long-term disposal rather than temporary storage.

Corrosion Resistance

Vitrification offers superior corrosion resistance compared to dry cask storage by immobilizing radioactive waste in a stable glass matrix that prevents leakage and chemical degradation over time.

Actinide Immobilization

Vitrification immobilizes actinides by encapsulating nuclear waste in stable glass matrices, whereas dry cask storage confines actinides within metal or concrete containers, relying on physical containment without chemical stabilization.

vitrification vs dry cask storage Infographic

njnir.com

njnir.com