Laser Isotope Separation (LIS) offers higher precision and faster enrichment rates compared to Gas Centrifuge technology, enabling selective excitation and ionization of specific isotopes for efficient separation. Gas Centrifuge relies on centrifugal force to separate isotopes based on mass differences, which is energy-efficient but slower and less selective than LIS. The advanced control and scalability of Laser Isotope Separation provide significant advantages for producing highly enriched uranium in nuclear engineering applications.

Table of Comparison

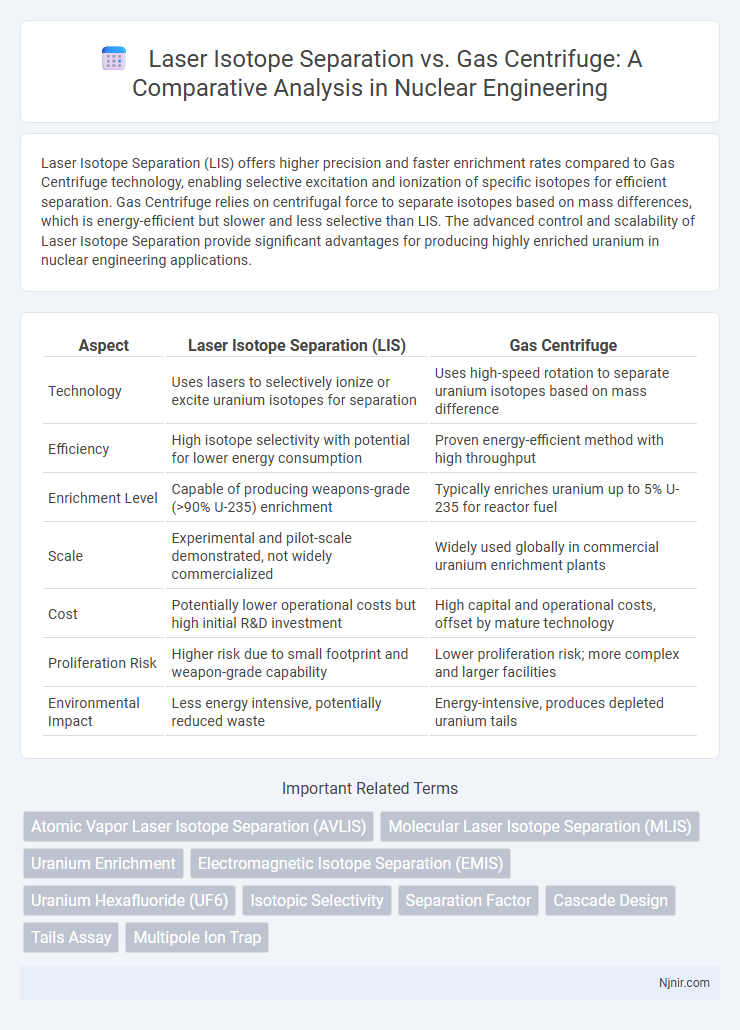

| Aspect | Laser Isotope Separation (LIS) | Gas Centrifuge |

|---|---|---|

| Technology | Uses lasers to selectively ionize or excite uranium isotopes for separation | Uses high-speed rotation to separate uranium isotopes based on mass difference |

| Efficiency | High isotope selectivity with potential for lower energy consumption | Proven energy-efficient method with high throughput |

| Enrichment Level | Capable of producing weapons-grade (>90% U-235) enrichment | Typically enriches uranium up to 5% U-235 for reactor fuel |

| Scale | Experimental and pilot-scale demonstrated, not widely commercialized | Widely used globally in commercial uranium enrichment plants |

| Cost | Potentially lower operational costs but high initial R&D investment | High capital and operational costs, offset by mature technology |

| Proliferation Risk | Higher risk due to small footprint and weapon-grade capability | Lower proliferation risk; more complex and larger facilities |

| Environmental Impact | Less energy intensive, potentially reduced waste | Energy-intensive, produces depleted uranium tails |

Introduction to Isotope Separation in Nuclear Engineering

Isotope separation is a critical process in nuclear engineering, enabling the enrichment of fissile materials like uranium-235 from natural uranium. Laser isotope separation (LIS) exploits precise atomic absorption and excitation properties to selectively ionize specific isotopes, offering high enrichment efficiency and reduced energy consumption. Gas centrifuge technology relies on rapid rotation to create a strong centrifugal field, separating isotopes based on mass differences with high throughput and established industrial scalability.

Overview of Laser Isotope Separation Technology

Laser Isotope Separation technology uses precise laser wavelengths to selectively excite specific isotopes, allowing for their efficient separation from a mixture. This method offers higher enrichment levels and greater selectivity compared to traditional Gas Centrifuge techniques, which rely on the mass difference of isotopes for separation through high-speed rotation. By enhancing isotopic purity with lower energy consumption, Laser Isotope Separation presents a promising alternative for uranium enrichment in nuclear fuel production.

Fundamentals of Gas Centrifuge Methods

Gas centrifuge methods separate isotopes by exploiting the mass difference between isotopic molecules, using high-speed rotation to generate a strong centrifugal force that drives heavier isotopes toward the outer edge of the rotor and lighter isotopes toward the center. The separation factor depends on rotor speed, temperature, and centrifuge geometry, enabling efficient enrichment of uranium-235 in uranium hexafluoride gas. Compared to laser isotope separation, gas centrifuges offer proven scalability and energy efficiency for large-scale uranium enrichment in nuclear fuel production.

Efficiency Comparison: Laser vs Gas Centrifuge

Laser Isotope Separation offers higher selectivity and faster processing speeds compared to Gas Centrifuge technology, significantly improving enrichment efficiency by targeting specific isotopes with precision. Gas Centrifuges rely on high-speed rotation to separate isotopes based on mass difference, resulting in lower throughput and greater energy consumption per separative work unit (SWU). Consequently, Laser methods show potential for reducing operational costs and minimizing energy usage in isotope enrichment applications.

Technological Requirements and Infrastructure

Laser isotope separation demands highly specialized laser systems with precise wavelength tuning and advanced optics to selectively excite isotopes, requiring cleanroom environments and robust safety protocols due to high-energy equipment. Gas centrifuge technology relies on the development of ultra-high-strength rotors made from carbon fiber or maraging steel, along with sophisticated bearing and vacuum systems to maintain stable, high-speed rotation essential for isotope separation. Infrastructure for laser methods includes controlled facilities with stringent air quality and vibration controls, whereas gas centrifuge plants require large-scale mechanical assembly areas, extensive power supply, and complex cascade configurations for efficient enrichment.

Uranium Enrichment Purity and Output

Laser Isotope Separation achieves higher uranium enrichment purity by utilizing precise laser wavelengths to selectively ionize U-235 isotopes, resulting in enrichment levels exceeding 90% with minimal uranium-238 contamination. Gas centrifuge technology typically produces enrichment up to 5-20% U-235 by exploiting centrifugal forces to separate isotopes, offering larger output capacity but lower purity compared to laser methods. The output rate of gas centrifuges is significantly higher due to continuous processing and scalability, while laser isotope separation provides superior enrichment quality ideal for specialized applications requiring weapons-grade uranium.

Cost Analysis: Capital and Operational Expenses

Laser Isotope Separation technology demands significantly higher capital investment due to advanced laser systems and precise control mechanisms compared to the relatively mature and widely implemented gas centrifuge technology. Operational expenses for laser isotope separation include substantial power consumption and specialized maintenance for lasers, whereas gas centrifuge facilities benefit from lower energy usage and established maintenance protocols, reducing long-term costs. Despite higher initial and operational costs, laser isotope separation offers potential advantages in efficiency and enrichment speed, which may offset expenses in specific high-throughput scenarios.

Security and Proliferation Risks

Laser Isotope Separation (LIS) offers higher enrichment efficiency and compact facility size, increasing proliferation risks due to easier concealment and rapid production of weapons-grade material compared to Gas Centrifuge technology. Gas Centrifuges, while established and widely monitored, require substantial infrastructure and energy, making covert operations more challenging but still pose significant security concerns due to their modularity and scalability. Both technologies demand stringent international safeguards, but LIS's advanced concealment potential and lower detectability heighten the urgency for enhanced nonproliferation measures.

Environmental Impact and Waste Management

Laser Isotope Separation produces significantly less chemical waste compared to Gas Centrifuge, reducing the environmental footprint during uranium enrichment. Gas Centrifuge processes generate larger volumes of depleted uranium tails requiring long-term storage solutions, increasing the burden on waste management systems. The energy efficiency of Laser Isotope Separation also lowers overall greenhouse gas emissions associated with isotope enrichment operations.

Future Trends and Innovations in Isotope Separation

Laser isotope separation advances with ultra-precise tunable lasers improving selectivity and reducing energy consumption, presenting a future of scalable, cost-effective enrichment. Gas centrifuge technology benefits from materials science innovations such as carbon fiber composites that enhance rotor strength and efficiency, extending operational lifespan and reducing maintenance. Integration of AI and real-time monitoring in both techniques drives optimization, predictive maintenance, and increased throughput in isotope separation plants.

Atomic Vapor Laser Isotope Separation (AVLIS)

Atomic Vapor Laser Isotope Separation (AVLIS) offers higher precision and efficiency in uranium enrichment compared to gas centrifuge methods by selectively ionizing specific isotopes using finely tuned laser frequencies.

Molecular Laser Isotope Separation (MLIS)

Molecular Laser Isotope Separation (MLIS) offers higher selectivity and energy efficiency for uranium enrichment compared to gas centrifuge methods by using tailored laser frequencies to excite specific isotopes in gaseous uranium hexafluoride.

Uranium Enrichment

Laser Isotope Separation achieves higher uranium-235 enrichment efficiency by selectively ionizing isotopes with precise laser frequencies, whereas gas centrifuge relies on centrifugal force to separate isotopes based on mass differences.

Electromagnetic Isotope Separation (EMIS)

Electromagnetic Isotope Separation (EMIS) uses magnetic fields to separate isotopes by mass, offering higher precision but lower throughput compared to Laser Isotope Separation and Gas Centrifuge methods.

Uranium Hexafluoride (UF6)

Laser Isotope Separation achieves higher precision in enriching Uranium Hexafluoride (UF6) by selectively exciting specific isotopes, whereas Gas Centrifuge relies on centrifugal force to separate isotopes based on mass differences.

Isotopic Selectivity

Laser isotope separation achieves isotopic selectivity by targeting atomic or molecular absorption lines with high precision, enabling separation of isotopes with minimal overlap, whereas gas centrifuge separation relies on mass differences and centrifugal forces, resulting in comparatively lower isotopic selectivity.

Separation Factor

Laser isotope separation achieves significantly higher separation factors, often exceeding 100, compared to typical gas centrifuge separation factors of 1.2 to 1.4 per stage, enabling more efficient isotope enrichment.

Cascade Design

Laser isotope separation enables precise, selective enrichment in compact cascades, while gas centrifuge cascades rely on multiple stages with high-speed rotors to achieve gradual isotope separation efficiency.

Tails Assay

Laser Isotope Separation achieves a significantly lower tails assay compared to Gas Centrifuge, enhancing uranium enrichment efficiency and reducing feedstock waste.

Multipole Ion Trap

Laser isotope separation achieves higher precision enrichment by selectively ionizing isotopes in a multipole ion trap, enhancing isotope separation efficiency compared to the centrifugal force-based gas centrifuge method.

Laser Isotope Separation vs Gas Centrifuge Infographic

njnir.com

njnir.com