TRISO fuel particles offer superior safety due to their robust ceramic coatings that contain fission products effectively under extreme conditions, unlike traditional oxide fuels which are more susceptible to melting and releasing radioactive materials during accidents. The high-temperature resilience and enhanced structural integrity of TRISO fuel enable higher burn-up rates, improving reactor efficiency and fuel utilization compared to conventional oxide fuels. These properties make TRISO fuel particularly suitable for advanced high-temperature reactors and designs prioritizing increased safety margins and long-term sustainability.

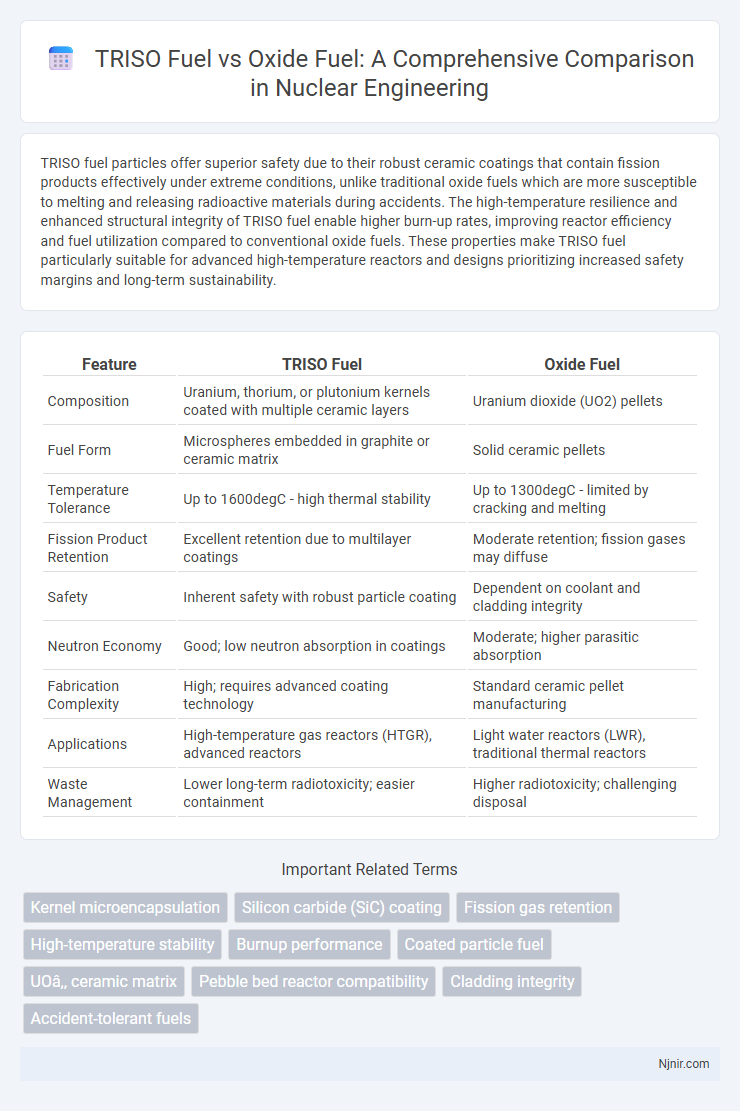

Table of Comparison

| Feature | TRISO Fuel | Oxide Fuel |

|---|---|---|

| Composition | Uranium, thorium, or plutonium kernels coated with multiple ceramic layers | Uranium dioxide (UO2) pellets |

| Fuel Form | Microspheres embedded in graphite or ceramic matrix | Solid ceramic pellets |

| Temperature Tolerance | Up to 1600degC - high thermal stability | Up to 1300degC - limited by cracking and melting |

| Fission Product Retention | Excellent retention due to multilayer coatings | Moderate retention; fission gases may diffuse |

| Safety | Inherent safety with robust particle coating | Dependent on coolant and cladding integrity |

| Neutron Economy | Good; low neutron absorption in coatings | Moderate; higher parasitic absorption |

| Fabrication Complexity | High; requires advanced coating technology | Standard ceramic pellet manufacturing |

| Applications | High-temperature gas reactors (HTGR), advanced reactors | Light water reactors (LWR), traditional thermal reactors |

| Waste Management | Lower long-term radiotoxicity; easier containment | Higher radiotoxicity; challenging disposal |

Introduction to Nuclear Fuel Types

TRISO fuel, composed of uranium kernels coated with multiple protective layers, offers enhanced safety and high-temperature stability compared to traditional oxide fuel, which primarily consists of uranium dioxide (UO2) pellets. Oxide fuel is widely used in conventional light water reactors due to its ease of fabrication and established performance, while TRISO fuel is favored in advanced reactors for its superior fission product retention and resistance to meltdown. The choice between TRISO and oxide fuel impacts reactor design, operational efficiency, and safety protocols within the nuclear energy industry.

What is TRISO Fuel?

TRISO fuel consists of tiny ceramic fuel particles coated with multiple layers of carbon and silicon carbide, providing exceptional containment of fission products. This design enhances safety and thermal stability compared to traditional oxide fuel, which typically uses uranium oxide pellets. TRISO fuel's robust structure enables higher temperature operation and improved resistance to radiation damage in advanced nuclear reactors.

What is Oxide Fuel?

Oxide fuel, commonly uranium dioxide (UO2), is a ceramic material used in nuclear reactors for its high melting point and chemical stability under irradiation. It allows efficient fission reactions by containing fissile isotopes like U-235 or plutonium within a solid matrix. Compared to TRISO fuel, oxide fuel has a simpler structure but typically lower resistance to temperature and fission product release during accidents.

Structural Differences: TRISO vs Oxide

TRISO fuel consists of uranium particles encapsulated in multiple layers of carbon and ceramic materials, providing enhanced containment and fission product retention compared to conventional oxide fuel, which is primarily composed of uranium dioxide pellets. The multi-layered structure of TRISO particles includes a porous carbon buffer, inner pyrolytic carbon, silicon carbide, and outer pyrolytic carbon, resulting in superior mechanical strength and high-temperature resilience. In contrast, oxide fuel's monolithic pellet form lacks these layered barriers, making it more susceptible to cracking and fission gas release under extreme operating conditions.

Neutronic Performance Comparison

TRISO fuel exhibits superior neutronic performance compared to oxide fuel due to its ability to maintain high fissile material density while enhancing neutron economy through effective fission product retention and reduced neutron absorption. The robust ceramic coatings in TRISO particles allow higher burnup and improved safety margins, enabling better neutron flux utilization and lower resonance absorption. Oxide fuel, with higher neutron capture cross-section in the matrix, generally results in lower reactivity and reduced fuel cycle efficiency compared to TRISO fuel configurations.

Thermal Conductivity and Heat Management

TRISO fuel exhibits superior thermal conductivity compared to oxide fuel, enhancing heat transfer efficiency within nuclear reactors. Its multilayered ceramic coatings facilitate effective heat management by preventing fission product release and enabling higher temperature operation. This allows TRISO fuel to maintain structural integrity and safety margins under increased thermal loads, unlike conventional oxide fuels.

Safety Features and Accident Tolerance

TRISO fuel offers superior safety features compared to conventional oxide fuel due to its robust multi-layered ceramic coating that encapsulates the fuel kernel, effectively containing fission products even at high temperatures. This micro-encapsulation enhances accident tolerance by preventing fuel particle failure during extreme conditions such as meltdown scenarios, reducing the risk of radioactive release. In contrast, oxide fuel, primarily used in light water reactors, has lower thermal conductivity and structural resilience, making it more vulnerable to degradation and fission product leakage under accident conditions.

Fuel Cycle and Waste Management

TRISO fuel offers enhanced safety and waste management benefits compared to conventional oxide fuel due to its robust ceramic coatings that retain fission products and enable higher burnup rates, resulting in less long-lived radioactive waste. The fuel cycle for TRISO fuel is more flexible, allowing for improved recycling and potentially reducing the volume and radiotoxicity of spent fuel. Oxide fuel, while widely used, typically generates larger quantities of high-level waste requiring extensive cooling and long-term geological disposal strategies.

Current Applications and Reactor Compatibility

TRISO fuel is predominantly used in high-temperature gas-cooled reactors (HTGRs) and advanced reactors due to its superior fission product retention and high-temperature stability, making it ideal for next-generation nuclear systems. Oxide fuel, mainly uranium dioxide (UO2), remains the standard choice for most commercial light-water reactors (LWRs) because of its well-established fabrication process and compatibility with existing reactor designs. The compatibility of TRISO fuel with HTGRs enables enhanced safety margins and higher thermal efficiencies, while oxide fuel's widespread deployment supports the bulk of current nuclear power generation worldwide.

Future Prospects and Research Directions

TRISO fuel offers superior radiation resistance and higher temperature tolerance compared to traditional oxide fuel, making it a promising candidate for next-generation high-temperature reactors and advanced nuclear systems. Ongoing research focuses on optimizing TRISO layer materials to enhance fission product retention and extending fuel life under extreme operating conditions. Future prospects include integrating TRISO fuel in modular reactors and fusion-fission hybrids, aiming to improve safety, efficiency, and waste management in nuclear energy.

Kernel microencapsulation

TRISO fuel enhances nuclear reactor safety by encapsulating each uranium kernel within multiple ceramic layers, providing superior microencapsulation compared to conventional oxide fuel.

Silicon carbide (SiC) coating

Silicon carbide (SiC) coating in TRISO fuel provides superior mechanical strength, chemical stability, and high-temperature resistance compared to oxide fuel, enhancing fission product retention and reactor safety.

Fission gas retention

TRISO fuel exhibits superior fission gas retention compared to oxide fuel due to its multilayered kernel design that effectively contains gaseous fission products under high-temperature reactor conditions.

High-temperature stability

TRISO fuel demonstrates superior high-temperature stability compared to oxide fuel due to its robust multi-layered ceramic coating that retains structural integrity and fission products at temperatures exceeding 1600degC.

Burnup performance

TRISO fuel demonstrates superior burnup performance compared to oxide fuel due to its enhanced fission product retention and higher temperature tolerance.

Coated particle fuel

TRISO fuel, featuring multilayered ceramic coatings around uranium kernels, offers superior fission product containment and higher temperature tolerance compared to conventional oxide fuel.

UO₂ ceramic matrix

TRISO fuel offers superior safety and higher temperature tolerance compared to traditional UO2 oxide fuel ceramic matrix due to its multilayered particle design that enhances fission product retention.

Pebble bed reactor compatibility

TRISO fuel exhibits superior thermal stability, fission product retention, and high-temperature resilience compared to oxide fuel, making it more compatible and safer for use in pebble bed reactors.

Cladding integrity

TRISO fuel maintains superior cladding integrity compared to oxide fuel due to its robust multi-layer ceramic coating that effectively prevents fission product release and withstands high temperatures.

Accident-tolerant fuels

TRISO fuel exhibits superior accident tolerance compared to oxide fuel due to its robust silicon carbide layer and multiple coating layers that effectively contain fission products under extreme conditions.

TRISO fuel vs oxide fuel Infographic

njnir.com

njnir.com