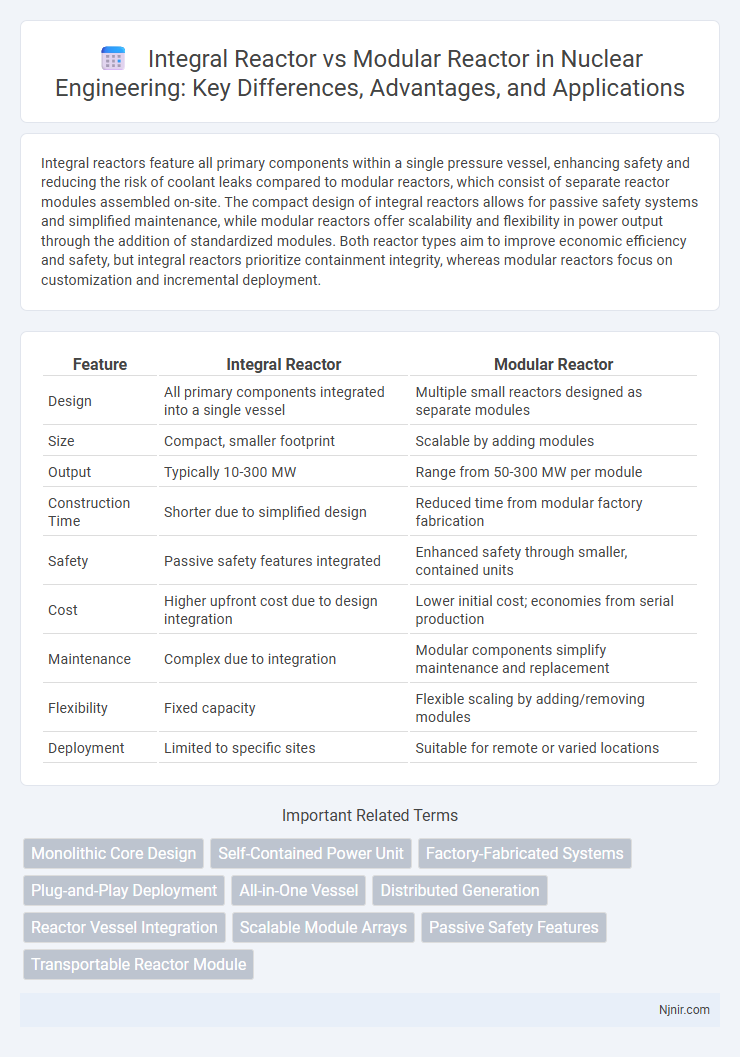

Integral reactors feature all primary components within a single pressure vessel, enhancing safety and reducing the risk of coolant leaks compared to modular reactors, which consist of separate reactor modules assembled on-site. The compact design of integral reactors allows for passive safety systems and simplified maintenance, while modular reactors offer scalability and flexibility in power output through the addition of standardized modules. Both reactor types aim to improve economic efficiency and safety, but integral reactors prioritize containment integrity, whereas modular reactors focus on customization and incremental deployment.

Table of Comparison

| Feature | Integral Reactor | Modular Reactor |

|---|---|---|

| Design | All primary components integrated into a single vessel | Multiple small reactors designed as separate modules |

| Size | Compact, smaller footprint | Scalable by adding modules |

| Output | Typically 10-300 MW | Range from 50-300 MW per module |

| Construction Time | Shorter due to simplified design | Reduced time from modular factory fabrication |

| Safety | Passive safety features integrated | Enhanced safety through smaller, contained units |

| Cost | Higher upfront cost due to design integration | Lower initial cost; economies from serial production |

| Maintenance | Complex due to integration | Modular components simplify maintenance and replacement |

| Flexibility | Fixed capacity | Flexible scaling by adding/removing modules |

| Deployment | Limited to specific sites | Suitable for remote or varied locations |

Introduction to Integral and Modular Reactors

Integral reactors integrate the reactor core, steam generators, and pressurizers within a single pressure vessel, enhancing safety through compact design and reduced piping. Modular reactors consist of smaller, factory-fabricated units that can be assembled on-site, offering scalability and reduced construction time. Both reactor types aim to improve safety and economics but differ significantly in design complexity and deployment flexibility.

Core Design Differences

Integral reactors integrate the core, steam generators, and coolant pumps within a single pressure vessel, enhancing compactness and safety by reducing the number of large-diameter pipes. Modular reactors consist of smaller, factory-built core modules that can be combined to scale output; they often feature separate components connected externally, allowing flexible assembly and maintenance. Core design in integral reactors emphasizes simplified thermal-hydraulic management inside a unified vessel, while modular reactors prioritize standardized, replicable core units optimized for factory fabrication and deployment.

Safety Features Comparison

Integral reactors integrate the core, steam generators, and pressurizer within a single pressure vessel, significantly reducing the risk of coolant leaks and enhancing passive safety systems. Modular reactors employ smaller, factory-fabricated units with inherent safety features such as passive cooling and simplified designs to enable rapid deployment and improved containment. Both designs prioritize mitigating accident scenarios, but integral reactors emphasize reduced piping and components, while modular reactors focus on scalability and fail-safe operation.

Construction and Deployment Timelines

Integral reactors typically feature a compact, factory-fabricated design that significantly reduces onsite construction time to approximately 2-3 years compared to traditional plants. Modular reactors leverage standardized, prefabricated modules, enabling parallel manufacturing and assembly processes that further shorten deployment timelines to as little as 18-24 months. Both technologies aim to accelerate nuclear project completion while enhancing safety through streamlined construction methodologies.

Operational Flexibility

Integral reactors offer enhanced operational flexibility by integrating primary components within a single pressure vessel, enabling simpler startup and shutdown procedures while reducing the risk of leaks. Modular reactors provide scalability and rapid deployment, allowing operators to adjust capacity based on demand and perform maintenance on individual modules without affecting the entire power plant. Both reactor types improve grid responsiveness, but modular reactors excel in adapting to fluctuating energy needs due to their modular design.

Economic Considerations

Integral reactors typically have lower upfront capital costs due to their compact design and reduced complexity, which simplifies construction and installation. Modular reactors offer economic advantages through factory fabrication, enabling mass production, reduced construction time, and scalable deployment that can match demand growth. Both designs aim to lower overall project risk and financing costs, but modular reactors may provide better cash flow management and adaptability in energy markets.

Scalability and Expansion Potential

Integral reactors offer limited scalability due to their compact, self-contained design, which integrates primary components into a single unit, restricting expansion options. Modular reactors feature a scalable architecture, allowing incremental capacity increases by adding standardized modules, making them ideal for phased deployment and flexible power output. The modular approach facilitates easier site expansion and cost containment compared to integral reactors, which often require complete system upgrades for capacity enhancement.

Maintenance and Refueling Strategies

Integral reactors feature a fully enclosed design with primary components housed within a single pressure vessel, significantly reducing the frequency and complexity of maintenance procedures. Modular reactors utilize factory-built, transportable modules that enable quicker onsite installation and facilitate streamlined maintenance by allowing individual modules to be isolated or replaced without shutting down the entire plant. Refueling in integral reactors typically involves extended operational cycles with on-site refueling ports, while modular reactors benefit from shorter refueling intervals due to their scalable deployment and modular nature.

Regulatory and Licensing Challenges

Integral reactors face stringent regulatory hurdles due to their novel design integrating core components within a single pressure vessel, requiring extensive safety validation and licensing adaptations. Modular reactors encounter regulatory challenges stemming from the need for standardized approvals across diverse sites, demanding flexible yet rigorous frameworks accommodating factory fabrication and on-site assembly. Both technologies necessitate updated regulatory guidelines to address unique safety features, passive cooling systems, and scalable deployment models.

Future Prospects in Nuclear Power Generation

Integral reactors offer enhanced safety through compact design and passive cooling systems, positioning them as viable options for small-scale power generation and remote applications. Modular reactors provide scalable deployment with factory-fabricated units, reducing construction times and costs, which supports the rapid expansion of nuclear capacity to meet growing energy demands. Both technologies are pivotal in advancing nuclear power's role in achieving low-carbon energy targets and addressing future grid flexibility challenges.

Monolithic Core Design

Integral reactors feature a monolithic core design that integrates core and primary components into a single compact unit, enhancing safety and simplifying maintenance compared to modular reactors with separate, interchangeable modules.

Self-Contained Power Unit

Integral reactors feature self-contained power units with primary components integrated within a single vessel, enhancing safety and compactness compared to modular reactors that assemble multiple separate modules for scalable power generation.

Factory-Fabricated Systems

Factory-fabricated integral reactors offer fully assembled, compact core and primary components for enhanced quality control and reduced on-site construction time compared to modular reactors, which consist of multiple prefabricated modules assembled at the plant site.

Plug-and-Play Deployment

Modular reactors enable faster plug-and-play deployment with factory-fabricated components, unlike integral reactors which have more complex, site-assembled systems.

All-in-One Vessel

Integral reactors consolidate the core, steam generators, and pressurizer within a single all-in-one vessel, enhancing safety and compactness compared to modular reactors that consist of separate components.

Distributed Generation

Integral reactors offer enhanced safety and compact design ideal for distributed generation compared to modular reactors, which provide scalability and flexibility but require more infrastructure.

Reactor Vessel Integration

Integral reactors feature a single, compact Reactor Vessel Integration combining the core, steam generator, and pressurizer, while modular reactors use separate, factory-fabricated modules optimized for scalable deployment and simplified maintenance.

Scalable Module Arrays

Integral reactors feature compact, self-contained designs ideal for scalable module arrays, enabling flexible capacity expansion and enhanced safety compared to traditional modular reactors.

Passive Safety Features

Integral reactors enhance passive safety by incorporating all primary components within a single pressure vessel to minimize leak risks, while modular reactors emphasize passive safety through scalable, factory-built units designed for inherent shutdown and heat removal without active controls.

Transportable Reactor Module

Transportable integral reactor modules offer enhanced safety, compact design, and simplified deployment compared to traditional modular reactors, enabling efficient off-grid power generation and rapid installation in remote locations.

integral reactor vs modular reactor Infographic

njnir.com

njnir.com