Pebble bed reactors utilize spherical fuel elements that enhance heat transfer and maintain a passive safety mechanism by naturally preventing overheating. Unlike conventional reactors with large fuel assemblies, pebble bed designs offer continuous fuel loading and online refueling, increasing operational flexibility and reducing downtime. This modular approach improves neutron economy and reduces the risk of meltdown, making pebble bed reactors a promising advancement in nuclear engineering.

Table of Comparison

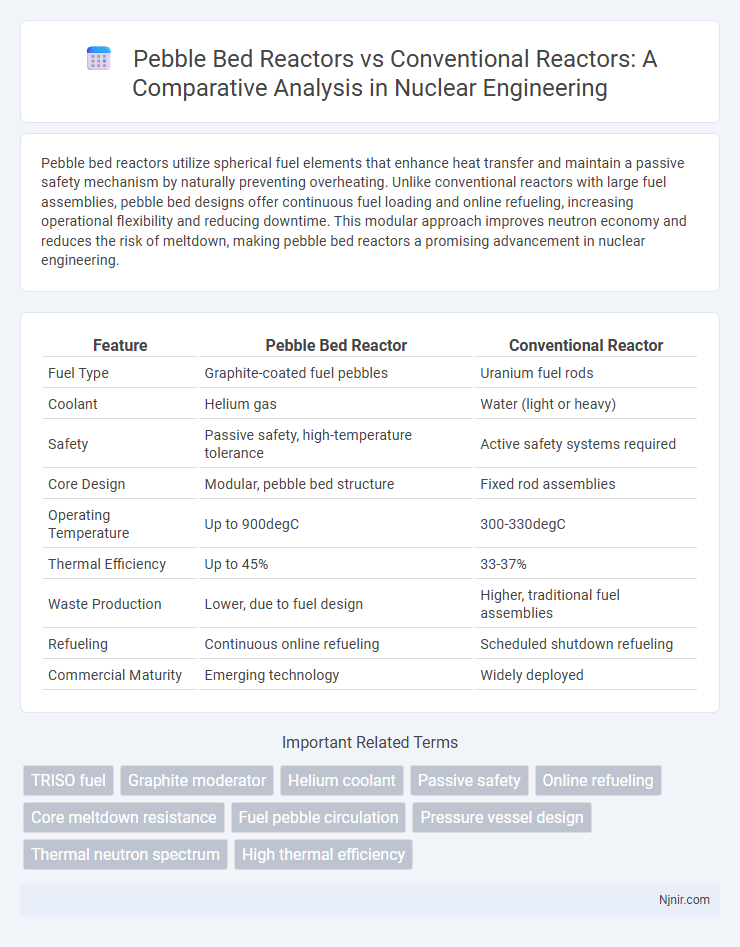

| Feature | Pebble Bed Reactor | Conventional Reactor |

|---|---|---|

| Fuel Type | Graphite-coated fuel pebbles | Uranium fuel rods |

| Coolant | Helium gas | Water (light or heavy) |

| Safety | Passive safety, high-temperature tolerance | Active safety systems required |

| Core Design | Modular, pebble bed structure | Fixed rod assemblies |

| Operating Temperature | Up to 900degC | 300-330degC |

| Thermal Efficiency | Up to 45% | 33-37% |

| Waste Production | Lower, due to fuel design | Higher, traditional fuel assemblies |

| Refueling | Continuous online refueling | Scheduled shutdown refueling |

| Commercial Maturity | Emerging technology | Widely deployed |

Introduction to Pebble Bed and Conventional Reactors

Pebble bed reactors utilize spherical fuel elements called pebbles, which contain nuclear fuel embedded in graphite, allowing for high thermal efficiency and enhanced safety features due to passive cooling and inherent negative temperature coefficients. Conventional reactors, typically light water reactors, use solid fuel rods arranged in assemblies within a water-cooled and moderated core, relying on active cooling systems and control rods for reactivity management. The pebble bed design enables continuous fueling and online refueling without shutdown, whereas conventional reactors require scheduled shutdowns for refueling and maintenance.

Fundamental Design Differences

Pebble bed reactors use spherical fuel elements called pebbles composed of uranium fuel encased in graphite, enabling high-temperature gas cooling and inherent safety features such as passive heat removal. Conventional reactors typically use solid fuel rods arranged in assemblies and rely on water as a coolant and moderator, which limits operating temperatures and introduces active safety systems. The pebble bed design facilitates continuous fuel loading and online refueling, contrasting with the batch refueling approach in conventional reactors.

Fuel Types and Handling Mechanisms

Pebble bed reactors utilize spherical fuel elements, typically coated uranium dioxide or thorium fuel encased in graphite, allowing continuous online refueling and efficient heat transfer, unlike conventional reactors that use solid fuel rods arranged in fixed assemblies requiring periodic shutdowns for refueling. The pebble bed design enables passive safety features and simpler handling through modular pebbles, while conventional reactors rely on complex coolant systems and extensive handling protocols for fuel rods. The flexibility in fuel management of pebble bed reactors reduces downtime and enhances operational efficiency compared to traditional light water reactors.

Core Configuration and Operation

Pebble bed reactors utilize spherical fuel elements called pebbles made of graphite pebbles embedded with TRISO fuel particles, arranged in a random packing within the core, facilitating continuous refueling and improved cooling efficiency. Conventional reactors typically use solid fuel rods arranged in a fixed lattice geometry within the reactor core, requiring shutdown for refueling, which limits operational flexibility. The pebble bed design allows for higher temperature operation and enhanced passive safety due to greater surface area and inherent cooling characteristics compared to the rigid core structure and lower operating temperatures of conventional reactors.

Safety Features and Passive Safety Systems

Pebble bed reactors utilize spherical fuel elements and helium coolant, enabling high thermal conductivity and inherent safety due to low power density and robust fuel design, which significantly reduces meltdown risk compared to conventional reactors. Their passive safety systems rely on natural convection and the refractory nature of coated fuel particles to maintain cooling without external power or active controls, offering enhanced resistance to overheating. Conventional reactors depend heavily on active safety systems such as emergency core cooling and control rods, while pebble bed designs prioritize fail-safe physical properties and passive heat dissipation mechanisms.

Thermal Efficiency and Power Output

Pebble bed reactors achieve higher thermal efficiency, typically around 45%, due to their continuous fuel movement and better heat transfer characteristics compared to conventional reactors, which average 33-37%. The modular design of pebble bed reactors allows for scalable power output, commonly ranging from 100 to 300 MW per module, while conventional reactors often exceed 1000 MW but with less flexibility in scaling. Enhanced coolant flow and inherent safety features in pebble bed reactors contribute to maintaining optimal operating temperatures, improving overall energy conversion efficiency.

Waste Management Approaches

Pebble bed reactors generate significantly less long-lived radioactive waste compared to conventional light-water reactors, reducing the burden on geological disposal facilities. Their fuel, composed of graphite spheres coated with TRISO particles, allows for continuous online refueling and minimizes spent fuel handling risks. This design enhances waste management by enabling more efficient containment and potential recycling of spent pebbles, improving overall nuclear waste sustainability.

Construction, Maintenance, and Cost Analysis

Pebble bed reactors feature modular construction using spherical fuel elements, significantly reducing build time and complexity compared to the large, welded pressure vessels in conventional reactors. Maintenance in pebble bed reactors is streamlined by continuous fuel circulation and online refueling, minimizing downtime unlike the extensive shutdowns needed for conventional reactor fuel replacement. Cost analysis highlights lower operational and decommissioning expenses for pebble bed designs due to enhanced safety features and simplified maintenance, although initial capital costs can be competitive depending on scale and technology maturity.

Applications and Deployment Status

Pebble bed reactors are primarily used for high-temperature process heat and electricity generation with enhanced safety features, making them suitable for industrial applications and remote locations. Conventional reactors dominate global deployment, powering the majority of nuclear grids with well-established infrastructure and extensive regulatory frameworks. Current deployment of pebble bed reactors remains limited, with demonstration projects in countries like China and South Africa, while conventional reactors continue widespread commercial operation worldwide.

Future Prospects and Technological Advancements

Pebble bed reactors offer enhanced safety through inherent passive cooling and modular design, presenting promising advancements over conventional light-water reactors in future nuclear power applications. Their capability for higher temperature operation improves thermal efficiency and hydrogen production potential, aligning with clean energy goals. Ongoing research focuses on fuel pebble durability and waste reduction, positioning pebble bed technology as a key player in next-generation nuclear innovation.

TRISO fuel

Pebble bed reactors utilize TRISO fuel particles embedded in graphite pebbles, providing enhanced safety and higher temperature tolerance compared to conventional reactors with traditional fuel rods.

Graphite moderator

Pebble bed reactors utilize graphite moderators embedded in fuel pebbles to enhance neutron moderation and high-temperature stability, whereas conventional reactors typically use solid graphite blocks or light water as moderators with lower thermal efficiency.

Helium coolant

The pebble bed reactor uses helium coolant for superior high-temperature heat transfer and chemical inertness compared to water or liquid metal coolants in conventional reactors.

Passive safety

Pebble bed reactors enhance passive safety through inherent cooling features and low pressure operation, reducing the risk of meltdown compared to conventional reactors relying on active safety systems.

Online refueling

Pebble bed reactors enable continuous online refueling by replacing fuel pebbles during operation, unlike conventional reactors that require shutdown for batch refueling.

Core meltdown resistance

Pebble bed reactors exhibit significantly higher core meltdown resistance compared to conventional reactors due to their inherent passive cooling features and robust fuel design.

Fuel pebble circulation

Fuel pebble circulation in pebble bed reactors enhances continuous fuel recycling and heat removal efficiency compared to the static, batch-loaded fuel rods in conventional reactors.

Pressure vessel design

Pebble bed reactors feature a compact, high-strength pressure vessel design that enables higher operating pressures and improved safety compared to the larger, heavier pressure vessels of conventional reactors.

Thermal neutron spectrum

Pebble bed reactors utilize a thermal neutron spectrum moderated by graphite spheres, enhancing neutron economy and fuel utilization compared to conventional reactors that rely on water moderation.

High thermal efficiency

Pebble bed reactors achieve higher thermal efficiency than conventional reactors by utilizing continuous fuel circulation and improved heat transfer in spherical fuel elements.

pebble bed reactor vs conventional reactor Infographic

njnir.com

njnir.com