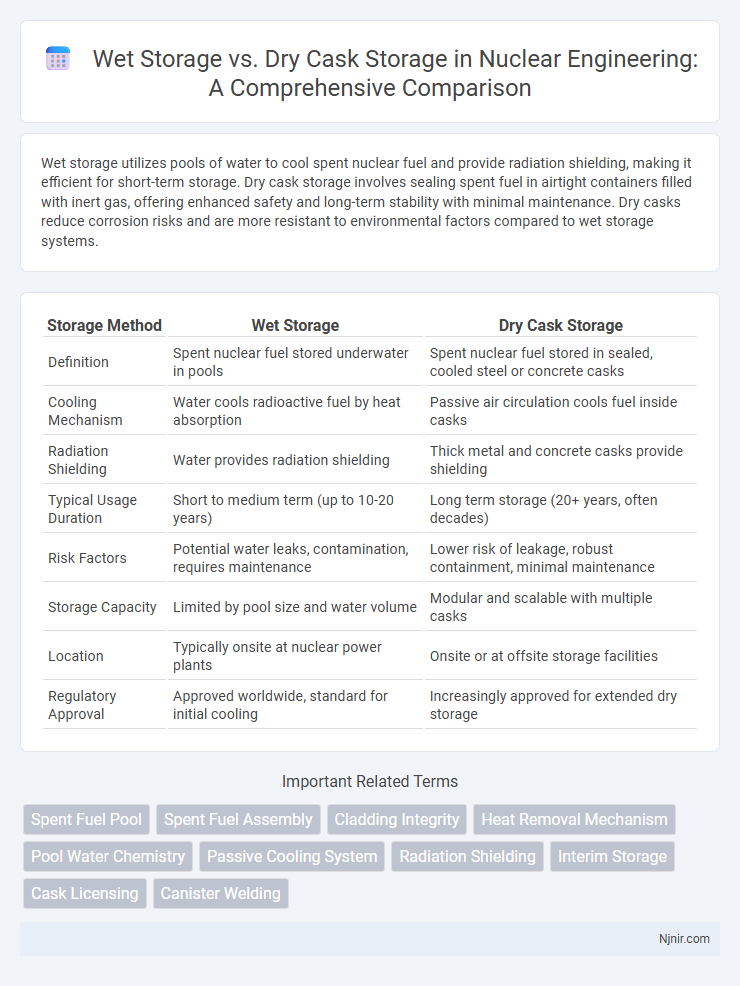

Wet storage utilizes pools of water to cool spent nuclear fuel and provide radiation shielding, making it efficient for short-term storage. Dry cask storage involves sealing spent fuel in airtight containers filled with inert gas, offering enhanced safety and long-term stability with minimal maintenance. Dry casks reduce corrosion risks and are more resistant to environmental factors compared to wet storage systems.

Table of Comparison

| Storage Method | Wet Storage | Dry Cask Storage |

|---|---|---|

| Definition | Spent nuclear fuel stored underwater in pools | Spent nuclear fuel stored in sealed, cooled steel or concrete casks |

| Cooling Mechanism | Water cools radioactive fuel by heat absorption | Passive air circulation cools fuel inside casks |

| Radiation Shielding | Water provides radiation shielding | Thick metal and concrete casks provide shielding |

| Typical Usage Duration | Short to medium term (up to 10-20 years) | Long term storage (20+ years, often decades) |

| Risk Factors | Potential water leaks, contamination, requires maintenance | Lower risk of leakage, robust containment, minimal maintenance |

| Storage Capacity | Limited by pool size and water volume | Modular and scalable with multiple casks |

| Location | Typically onsite at nuclear power plants | Onsite or at offsite storage facilities |

| Regulatory Approval | Approved worldwide, standard for initial cooling | Increasingly approved for extended dry storage |

Introduction to Spent Nuclear Fuel Management

Spent nuclear fuel management involves two primary storage methods: wet storage and dry cask storage. Wet storage uses pools of water to cool and shield radioactive fuel immediately after removal from the reactor, providing both heat dissipation and radiation protection. Dry cask storage transfers cooled spent fuel into robust, sealed containers that rely on passive air cooling, offering a long-term, secure solution once fuel is no longer efficiently cooled in pools.

Overview of Wet Storage Technology

Wet storage technology utilizes large pools of water to cool and shield spent nuclear fuel from radiation, maintaining safe temperatures through continuous water circulation. The water acts as both a heat sink and a radiation barrier, effectively preventing fuel degradation while enabling ongoing monitoring. This method is widely adopted in nuclear power plants for short- to medium-term storage before transferring fuel to dry cask storage or reprocessing facilities.

Principles of Dry Cask Storage Systems

Dry cask storage systems use robust, sealed steel and concrete containers to safely contain spent nuclear fuel, relying on passive heat dissipation through natural convection and radiation. They eliminate the need for continuous water cooling by maintaining an inert gas atmosphere, minimizing corrosion and radiation leakage risks. This method ensures long-term containment and shielding, facilitating secure onsite or offsite storage of radioactive materials after initial cooling in wet pools.

Safety Considerations in Wet vs. Dry Storage

Wet storage systems use pools of water to cool and shield spent nuclear fuel, providing efficient heat removal and radiation protection while requiring continuous monitoring to prevent leaks or water contamination risks. Dry cask storage employs robust, sealed containers with passive air cooling, minimizing the risk of water-related accidents and offering enhanced resistance to natural disasters or external impacts. Safety considerations favor dry cask storage for long-term containment due to its passive safety features and reduced mechanical complexity compared to wet storage systems.

Cost Analysis of Storage Methods

Wet storage typically incurs higher operational costs due to continuous water treatment, cooling systems, and regular monitoring requirements, making it more expensive over the long term. Dry cask storage involves a higher initial capital expenditure for cask fabrication and facility construction but benefits from lower maintenance and operational costs, resulting in cost-effectiveness for extended storage periods. Economic assessments indicate that dry cask storage becomes more financially viable beyond 10-15 years of interim storage compared to wet storage pools.

Environmental Impact Comparison

Wet storage involves submerging spent nuclear fuel in pools of water, providing effective radiation shielding and heat removal but raising concerns about potential water contamination and thermal pollution. Dry cask storage uses sealed steel and concrete containers, minimizing risks of water contamination and reducing environmental exposure to radiation leaks, making it a safer long-term option. Studies indicate that dry casks have a smaller ecological footprint due to lower maintenance requirements and reduced vulnerability to weather-related incidents compared to wet storage pools.

Storage Capacity and Scalability

Wet storage, using spent fuel pools, offers limited capacity constrained by pool size and water volume, making scalability challenging for expanding nuclear waste inventories. Dry cask storage provides modular, scalable solutions with individual sealed containers that can be added incrementally, enhancing storage capacity without extensive infrastructure changes. This adaptability allows dry casks to accommodate increasing amounts of spent nuclear fuel more efficiently than fixed-capacity wet storage systems.

Regulatory and Licensing Requirements

Wet storage of spent nuclear fuel requires regulatory compliance with the Nuclear Regulatory Commission (NRC) standards outlined in 10 CFR Part 50 and 10 CFR Part 72, addressing pool design, radiation shielding, and cooling system integrity. Dry cask storage systems must obtain specific NRC licensing under 10 CFR Part 72, demonstrating robust safety analysis for containment, structural stability, and thermal performance to ensure long-term storage security. Both storage methods demand rigorous inspections, environmental impact assessments, and periodic license renewals to maintain regulatory approval and operational safety.

Long-Term Storage and Decommissioning

Wet storage utilizes pools of water to cool and shield spent nuclear fuel immediately after reactor discharge, but its long-term storage viability is limited by the need for continuous active maintenance and potential risks of water corrosion. Dry cask storage offers a more robust solution for long-term storage and decommissioning phases, using sealed, inert gas-filled containers that provide passive cooling and enhanced containment, reducing maintenance costs and improving safety. Regulatory bodies often prefer dry cask systems for extended interim storage due to their resilience against environmental degradation and easier site decommissioning processes.

Future Trends in Spent Fuel Storage Technologies

Future trends in spent fuel storage technologies emphasize enhancing safety, efficiency, and environmental sustainability, with dry cask storage gaining preference due to its robust containment and passive cooling systems. Innovations focus on improving materials to extend the lifespan of dry casks and integrating advanced monitoring technologies for real-time radiation and temperature control. Wet storage continues to evolve with improved water treatment and circulation systems, but dry cask systems are increasingly favored for long-term storage and transport applications.

Spent Fuel Pool

Spent Fuel Pools provide dense, water-filled storage for spent nuclear fuel, offering effective radiation shielding and cooling, whereas dry cask storage uses inert gas-filled steel and concrete containers for long-term, passive cooling outside reactor buildings.

Spent Fuel Assembly

Wet storage uses water pools to cool spent fuel assemblies and provide radiation shielding, while dry cask storage encloses them in shielded, inert gas-filled containers for long-term, passive cooling and enhanced safety.

Cladding Integrity

Wet storage maintains better cladding integrity by providing continuous water cooling that reduces corrosion risk, whereas dry cask storage relies on passive air cooling and may increase cladding degradation over extended periods.

Heat Removal Mechanism

Wet storage removes heat through continuous water circulation that absorbs and dissipates reactor decay heat, whereas dry cask storage relies on passive air convection and conduction through metal and concrete barriers to manage residual heat.

Pool Water Chemistry

Pool water chemistry in wet storage requires precise control of pH, temperature, and boron concentration to prevent corrosion and radiation release, whereas dry cask storage eliminates the need for continuous water chemistry management by using inert gas-filled, sealed containers.

Passive Cooling System

Dry cask storage utilizes a passive cooling system that relies on natural air circulation to dissipate heat from spent nuclear fuel, whereas wet storage depends on active water circulation and potential mechanical systems to maintain cooling.

Radiation Shielding

Dry cask storage provides enhanced radiation shielding by using thick concrete and steel barriers, while wet storage relies on water's radiation absorption properties but requires continuous maintenance to prevent radiation leakage.

Interim Storage

Interim storage for spent nuclear fuel utilizes wet storage pools for initial cooling and radiation shielding, while dry cask storage offers secure, passive containment for longer-term on-site management.

Cask Licensing

Dry cask storage requires comprehensive NRC licensing focused on cask design certification, safety analysis, and environmental impact assessments unlike wet storage, which primarily relies on reactor facility licenses.

Canister Welding

Canister welding in dry cask storage provides enhanced containment integrity and corrosion resistance compared to the continuous water exposure challenges faced in wet storage systems.

wet storage vs dry cask storage Infographic

njnir.com

njnir.com