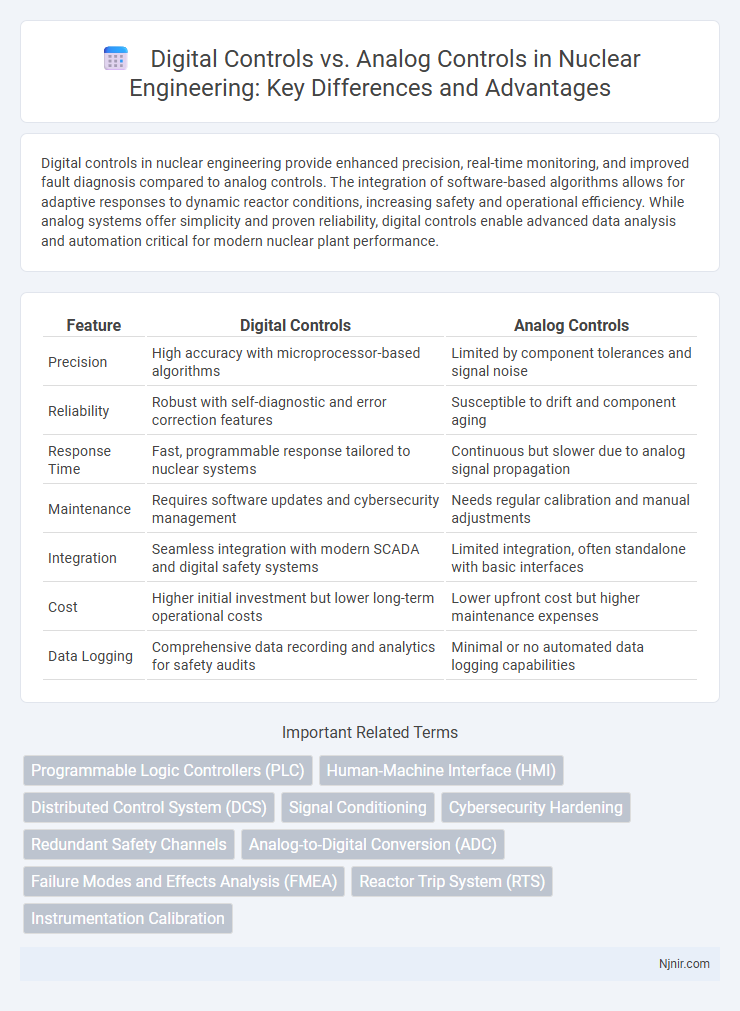

Digital controls in nuclear engineering provide enhanced precision, real-time monitoring, and improved fault diagnosis compared to analog controls. The integration of software-based algorithms allows for adaptive responses to dynamic reactor conditions, increasing safety and operational efficiency. While analog systems offer simplicity and proven reliability, digital controls enable advanced data analysis and automation critical for modern nuclear plant performance.

Table of Comparison

| Feature | Digital Controls | Analog Controls |

|---|---|---|

| Precision | High accuracy with microprocessor-based algorithms | Limited by component tolerances and signal noise |

| Reliability | Robust with self-diagnostic and error correction features | Susceptible to drift and component aging |

| Response Time | Fast, programmable response tailored to nuclear systems | Continuous but slower due to analog signal propagation |

| Maintenance | Requires software updates and cybersecurity management | Needs regular calibration and manual adjustments |

| Integration | Seamless integration with modern SCADA and digital safety systems | Limited integration, often standalone with basic interfaces |

| Cost | Higher initial investment but lower long-term operational costs | Lower upfront cost but higher maintenance expenses |

| Data Logging | Comprehensive data recording and analytics for safety audits | Minimal or no automated data logging capabilities |

Introduction to Control Systems in Nuclear Engineering

Digital controls in nuclear engineering offer precision and adaptability by processing discrete signals and enabling complex algorithms for system regulation, while analog controls rely on continuous signals to directly manipulate physical parameters. Control systems in nuclear reactors require reliable feedback loops and real-time adjustments to maintain safety and optimal performance, with digital controls enhancing fault detection and data logging capabilities. The integration of digital controls improves reactor stability, reduces human error, and supports advanced monitoring essential for modern nuclear plant operations.

Fundamentals of Analog Control Systems

Analog control systems operate through continuous signals that represent varying physical quantities, enabling precise real-time adjustments in process variables. These systems utilize components such as operational amplifiers, resistors, and capacitors to form feedback loops that maintain stability and improve accuracy. Key fundamentals include linearity, proportional-integral-derivative (PID) control, and frequency response, which collectively ensure smooth and responsive control in analog environments.

Fundamentals of Digital Control Systems

Digital control systems utilize discrete-time signals processed by microcontrollers or digital signal processors, enabling precise and adaptable manipulation of system variables. The fundamentals include sampling, quantization, and the use of difference equations to model and design control algorithms, contrasting with continuous analog signals in analog controls. Digital controls offer advantages such as programmability, improved noise immunity, and ease of implementation for complex control strategies compared to analog systems.

System Reliability and Redundancy

Digital controls enhance system reliability through precise error detection, real-time diagnostics, and automated fault isolation, reducing downtime and maintenance costs. Analog controls, while simpler, lack self-diagnostic capabilities and are more prone to drift and signal degradation, affecting consistent performance. Redundancy in digital control systems often includes duplicated processors and communication paths, allowing seamless failover, whereas analog systems rely on manual backup components, increasing recovery time.

Response Time and Operational Precision

Digital controls offer faster response times due to rapid signal processing and precise algorithmic adjustments, enabling real-time system corrections. Analog controls provide smoother and continuous signal variation, which can enhance operational precision in systems requiring fine-tuned sensitivity and low-latency feedback. The choice between digital and analog control systems depends on balancing the need for rapid response with the degree of precision required for specific applications.

Safety Considerations in Nuclear Applications

Digital controls in nuclear applications offer enhanced safety through precise monitoring, real-time diagnostics, and automated fault detection, reducing human error and improving response times during anomalies. Analog controls, while simpler and often more resilient to electromagnetic interference, lack the advanced data processing capabilities necessary for modern safety protocols and fail-safe mechanisms. Implementing digital systems requires rigorous cybersecurity measures to protect against hacking, ensuring that safety-critical operations remain secure and reliable.

Maintenance and Lifecycle Management

Digital controls offer simplified maintenance with software updates and remote diagnostics, reducing downtime and extending system lifespan. Analog controls require frequent manual calibration and component replacements, increasing maintenance complexity and costs over time. Lifecycle management favors digital controls due to enhanced fault detection, easier upgrades, and integration with predictive maintenance technologies.

Integration with Modern Monitoring Technologies

Digital controls offer seamless integration with modern monitoring technologies through advanced communication protocols like IoT, enabling real-time data acquisition and remote management. Analog controls lack compatibility with centralized monitoring systems, limiting their effectiveness in predictive maintenance and smart automation. Enhanced data analytics and cloud connectivity in digital controls significantly improve operational efficiency and decision-making processes.

Regulatory Compliance and Industry Standards

Digital controls provide enhanced precision and traceability crucial for meeting stringent regulatory compliance and industry standards such as FDA 21 CFR Part 11 and ISO 13485, enabling comprehensive audit trails and real-time data monitoring. Analog controls, while simpler, often lack the detailed documentation and automated reporting features necessary for full regulatory adherence, posing challenges during audits and validation processes. Industries with strict compliance requirements increasingly adopt digital control systems to ensure consistent quality, reduce errors, and maintain standardized operational protocols.

Future Trends in Nuclear Control Systems

Future trends in nuclear control systems emphasize the integration of advanced digital controls, leveraging machine learning algorithms and real-time data analytics to enhance safety and operational efficiency. Digital controls offer superior precision, fault detection, and automated response capabilities compared to traditional analog controls, enabling predictive maintenance and reducing human error. The shift towards digitalization also supports cybersecurity enhancements and remote monitoring, crucial for next-generation nuclear reactors and hybrid energy systems.

Programmable Logic Controllers (PLC)

Programmable Logic Controllers (PLCs) utilize digital controls for precise, reliable automation and real-time processing while analog controls offer variable signal handling but less integration flexibility in industrial applications.

Human-Machine Interface (HMI)

Digital controls in Human-Machine Interface (HMI) offer enhanced precision, real-time monitoring, and customizable user interfaces compared to traditional analog controls, enabling more efficient and intuitive machine operation.

Distributed Control System (DCS)

Distributed Control Systems (DCS) leverage digital controls to enhance precision, scalability, and real-time data integration compared to traditional analog controls, improving process automation and fault diagnostics in industrial environments.

Signal Conditioning

Digital controls offer precise, noise-resistant signal conditioning through advanced filtering and error correction, whereas analog controls rely on continuous voltage or current signals that are more susceptible to noise and signal degradation.

Cybersecurity Hardening

Digital controls offer enhanced cybersecurity hardening through robust encryption and real-time threat detection compared to analog controls' limited protection capabilities.

Redundant Safety Channels

Redundant safety channels in digital controls offer higher reliability and fault tolerance compared to analog controls by enabling real-time diagnostics and automated failover mechanisms.

Analog-to-Digital Conversion (ADC)

Analog-to-Digital Conversion (ADC) enables digital controls to process real-world analog signals with higher precision and flexibility compared to traditional analog controls, enhancing accuracy and system integration.

Failure Modes and Effects Analysis (FMEA)

Failure Modes and Effects Analysis (FMEA) reveals that digital controls exhibit enhanced fault detection and diagnostic capabilities compared to analog controls, which are more susceptible to signal degradation and component drift.

Reactor Trip System (RTS)

Digital controls in Reactor Trip Systems (RTS) offer enhanced precision, real-time monitoring, and improved fault diagnostics compared to traditional analog controls, enabling faster and more reliable reactor shutdowns.

Instrumentation Calibration

Digital controls provide higher precision and repeatability in instrumentation calibration compared to analog controls, enabling more accurate and consistent measurement adjustments.

digital controls vs analog controls Infographic

njnir.com

njnir.com