Enriched uranium contains a higher concentration of the fissile isotope uranium-235 compared to natural uranium, which typically has about 0.7% uranium-235. This increase enhances the efficiency of nuclear reactors and weapons by providing a more readily fissionable material. Natural uranium, with its lower uranium-235 content, often requires enrichment to meet the fuel requirements for most commercial nuclear reactors.

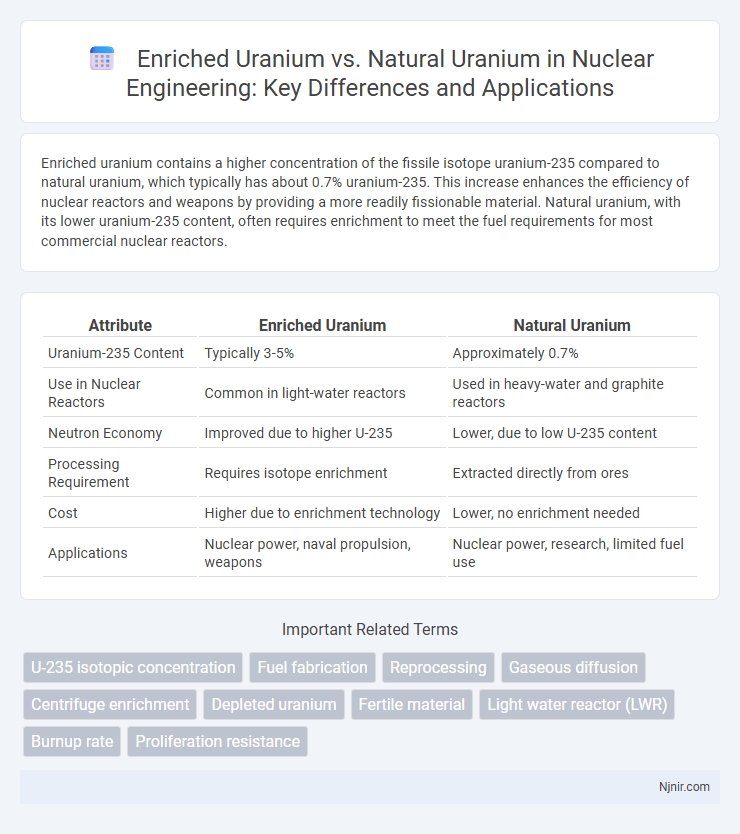

Table of Comparison

| Attribute | Enriched Uranium | Natural Uranium |

|---|---|---|

| Uranium-235 Content | Typically 3-5% | Approximately 0.7% |

| Use in Nuclear Reactors | Common in light-water reactors | Used in heavy-water and graphite reactors |

| Neutron Economy | Improved due to higher U-235 | Lower, due to low U-235 content |

| Processing Requirement | Requires isotope enrichment | Extracted directly from ores |

| Cost | Higher due to enrichment technology | Lower, no enrichment needed |

| Applications | Nuclear power, naval propulsion, weapons | Nuclear power, research, limited fuel use |

Overview of Uranium: Natural vs. Enriched

Natural uranium consists primarily of uranium-238 (about 99.3%) with a small fraction of uranium-235 (approximately 0.7%), the isotope crucial for nuclear fission. Enriched uranium has an increased concentration of uranium-235, typically between 3% and 5%, to enhance its efficiency as fuel in nuclear reactors and reduce fuel volume. The enrichment process separates uranium isotopes to boost reactivity, distinguishing enriched uranium's vital role in energy production and nuclear technology from natural uranium's raw mineral state.

Isotopic Composition Differences

Enriched uranium contains a higher percentage of the fissile isotope uranium-235, typically ranging from 3% to 5%, compared to natural uranium's 0.7% uranium-235 content. The remaining isotopes in enriched uranium predominantly consist of uranium-238, with a reduced proportion of uranium-234 relative to natural uranium. This increased uranium-235 concentration enhances the material's suitability for nuclear reactors and weapons due to improved neutron-induced fission efficiency.

Uranium Processing and Enrichment Methods

Enriched uranium undergoes uranium processing techniques such as gas centrifuge and gaseous diffusion to increase the concentration of uranium-235 isotopes from the 0.7% found in natural uranium to levels typically between 3-5% for nuclear reactors. Methods like laser isotope separation and advanced centrifugation enhance uranium-235 purity, enabling higher reactor efficiency and potential weapons-grade material production. Natural uranium, primarily composed of uranium-238, requires substantial enrichment to achieve the fissile characteristics necessary for most nuclear power generation applications.

Applications in Nuclear Power Generation

Enriched uranium, containing a higher concentration of uranium-235 isotopes (typically 3-5%), is primarily used as fuel in commercial nuclear reactors due to its improved fission efficiency compared to natural uranium, which contains about 0.7% uranium-235. Natural uranium is often utilized in heavy-water reactors and certain types of graphite-moderated reactors that can operate without enrichment. The enrichment process enhances reactor performance by increasing energy output and reducing fuel load while enabling longer operational cycles in nuclear power generation.

Weapons Potential: Security and Proliferation Risks

Enriched uranium, containing a higher concentration of U-235 isotope (typically above 20%), significantly increases weapons potential compared to natural uranium, which contains about 0.7% U-235. The enrichment process facilitates the production of nuclear weapons, raising critical security concerns and proliferation risks as enriched uranium is more readily weaponizable. Monitoring and controlling enriched uranium stockpiles are essential to prevent nuclear weapon development and enhance global non-proliferation efforts.

Fuel Cycle: From Mining to Reactor

Enriched uranium contains a higher concentration of the fissile isotope U-235 compared to natural uranium, which is approximately 0.7% U-235. The fuel cycle for enriched uranium involves mining natural uranium ore, conversion to uranium hexafluoride (UF6), enrichment through centrifugation or gaseous diffusion, fuel fabrication, and finally use in reactors for energy production. Natural uranium can be used directly in heavy water reactors or graphite-moderated reactors without enrichment, simplifying its fuel cycle but offering lower neutron efficiency and power output.

Economic Considerations: Costs and Market Impacts

Enriched uranium requires complex and energy-intensive processes such as gaseous diffusion or centrifugation, leading to higher production costs compared to natural uranium, which is more abundant and less expensive to mine. The enrichment process significantly impacts market prices, with enriched uranium commanding premium prices due to its suitability for nuclear reactors requiring higher fissile content. Economic considerations also include geopolitical factors and supply chain stability, as enriched uranium markets are influenced by international regulations and trade policies, affecting both cost and availability.

Environmental Implications of Enrichment

Enriched uranium contains a higher concentration of fissile U-235 isotopes compared to natural uranium, facilitating more efficient nuclear reactions but leading to increased environmental challenges such as radioactive waste generation and potential contamination risks during enrichment processes. The physical and chemical treatments involved in uranium enrichment often consume significant energy, contributing to greenhouse gas emissions and ecological disturbances. Managing depleted uranium tails and mitigating their long-term radiotoxicity remain critical concerns in the environmental assessment of uranium enrichment activities.

Handling, Transport, and Storage Challenges

Enriched uranium requires stricter handling protocols due to its higher radioactivity and proliferation risk compared to natural uranium. Transporting enriched uranium involves secure containment systems and regulatory oversight to prevent theft and environmental contamination. Storage challenges include maintaining criticality safety, radiation shielding, and long-term containment integrity to mitigate security and health hazards.

Regulatory and Safety Standards

Enriched uranium, containing a higher concentration of U-235 isotopes, is subject to stricter regulatory and safety standards compared to natural uranium due to its increased potential for nuclear proliferation and criticality risks. Regulatory bodies such as the Nuclear Regulatory Commission (NRC) and the International Atomic Energy Agency (IAEA) impose rigorous safeguards, including secure transportation, storage, and handling protocols for enriched uranium to prevent unauthorized access and ensure worker safety. Natural uranium, with its lower U-235 concentration, faces less stringent requirements but still must comply with standards addressing radiation exposure, environmental protection, and waste management.

U-235 isotopic concentration

Enriched uranium contains a higher U-235 isotopic concentration, typically between 3% and 5%, compared to natural uranium's 0.7%, enhancing its effectiveness as nuclear reactor fuel.

Fuel fabrication

Enriched uranium, containing a higher concentration of U-235 isotopes than natural uranium, allows for more efficient fuel fabrication by reducing the volume of material needed and enhancing reactor performance.

Reprocessing

Reprocessing enriched uranium involves chemically separating fissile U-235 from spent nuclear fuel to recycle it for reactor use, whereas natural uranium requires enrichment before use and its reprocessing primarily targets spent fuel management and plutonium recovery.

Gaseous diffusion

Gaseous diffusion is a critical process for enriching uranium by separating uranium-235 from natural uranium based on molecular weight differences of uranium hexafluoride gas.

Centrifuge enrichment

Centrifuge enrichment increases the concentration of U-235 in natural uranium from about 0.7% to 3-5% or higher, producing enriched uranium essential for nuclear reactors and weapons.

Depleted uranium

Depleted uranium, a byproduct of the enrichment process that reduces U-235 concentration from 0.7% in natural uranium to about 0.2%, is primarily used for military armor and radiation shielding due to its high density and low radioactivity.

Fertile material

Enriched uranium contains a higher concentration of fissile U-235 isotopes, while natural uranium primarily consists of fertile U-238 isotopes capable of breeding fissile material.

Light water reactor (LWR)

Enriched uranium, with a higher concentration of U-235 (typically 3-5%), is essential for Light Water Reactors (LWRs) to sustain efficient nuclear fission, unlike natural uranium which contains only about 0.7% U-235 and is insufficient for LWR fuel without enrichment.

Burnup rate

Enriched uranium achieves a significantly higher burnup rate compared to natural uranium, enhancing fuel efficiency and energy output in nuclear reactors.

Proliferation resistance

Enriched uranium poses higher proliferation risks than natural uranium due to its increased concentration of fissile U-235, making it more suitable for nuclear weapons development.

enriched uranium vs natural uranium Infographic

njnir.com

njnir.com