Dry cask storage provides a safer and more sustainable method for storing spent nuclear fuel compared to spent fuel pools by using robust, airtight containers that allow passive cooling through natural air circulation. Spent fuel pools, while effective for short-term cooling, pose higher risks of radiation release due to potential water leaks or evaporation, requiring continuous active cooling systems. The transition to dry cask storage enhances long-term containment stability and reduces reliance on active maintenance, making it a critical component in nuclear waste management strategies.

Table of Comparison

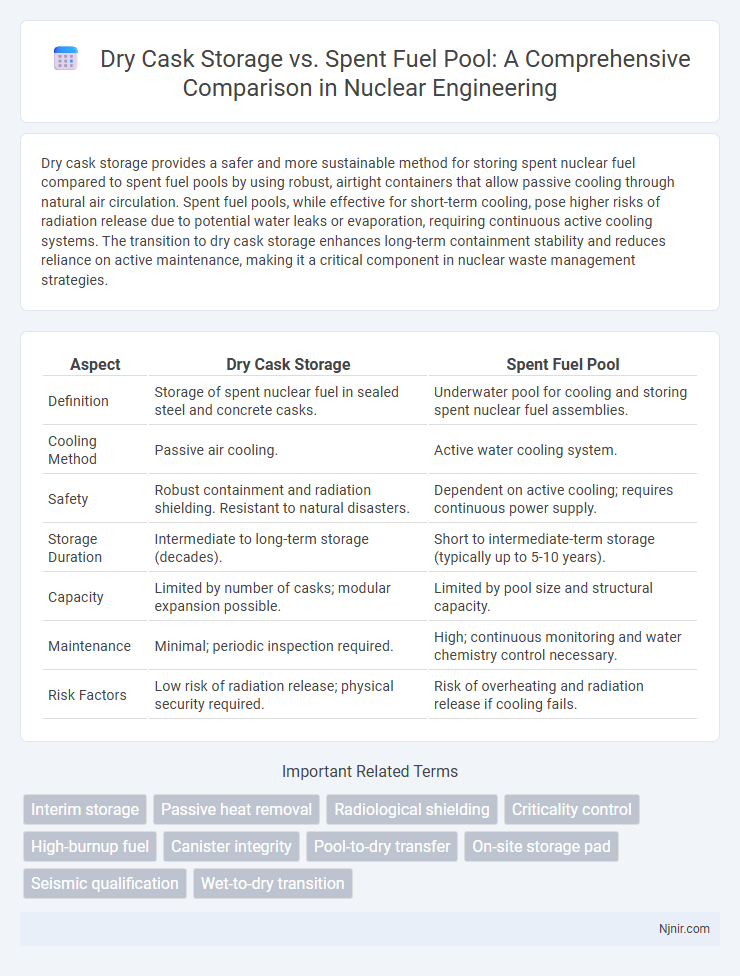

| Aspect | Dry Cask Storage | Spent Fuel Pool |

|---|---|---|

| Definition | Storage of spent nuclear fuel in sealed steel and concrete casks. | Underwater pool for cooling and storing spent nuclear fuel assemblies. |

| Cooling Method | Passive air cooling. | Active water cooling system. |

| Safety | Robust containment and radiation shielding. Resistant to natural disasters. | Dependent on active cooling; requires continuous power supply. |

| Storage Duration | Intermediate to long-term storage (decades). | Short to intermediate-term storage (typically up to 5-10 years). |

| Capacity | Limited by number of casks; modular expansion possible. | Limited by pool size and structural capacity. |

| Maintenance | Minimal; periodic inspection required. | High; continuous monitoring and water chemistry control necessary. |

| Risk Factors | Low risk of radiation release; physical security required. | Risk of overheating and radiation release if cooling fails. |

Introduction to Spent Nuclear Fuel Management

Spent nuclear fuel management involves safely storing used fuel assemblies after removal from reactors, primarily through spent fuel pools and dry cask storage. Spent fuel pools utilize water to cool and shield radiation, providing effective short-term storage with continuous monitoring. Dry cask storage offers robust, passive safety for long-term containment by enclosing fuel in sealed, inert gas-filled containers, reducing reliance on active cooling systems.

Overview of Spent Fuel Pools

Spent fuel pools are large pools of water used for cooling and shielding newly discharged spent nuclear fuel rods from reactors. These pools provide radiation protection and heat removal during the initial high-radioactivity period, typically storing fuel for 5 to 10 years before transfer. Unlike dry cask storage, spent fuel pools require continuous water circulation and active cooling systems to maintain safety and prevent overheating.

Fundamentals of Dry Cask Storage Systems

Dry cask storage systems fundamentally consist of robust steel and concrete containers designed to safely isolate spent nuclear fuel from the environment after cooling in spent fuel pools. These casks offer passive heat dissipation through natural convection and radiation, eliminating the need for active cooling systems required in pools. Their modular design enhances long-term storage security, reduces radiation exposure risks, and facilitates easier transportation and inspection of spent fuel assemblies.

Safety Considerations: Pool vs. Cask

Dry cask storage offers enhanced safety by isolating spent nuclear fuel in robust, airtight steel and concrete containers that shield radiation and withstand natural disasters. Spent fuel pools rely on water to cool and provide radiation shielding, but require continuous active cooling systems vulnerable to power outages and potential leaks. The passive safety features of dry casks reduce the risk of radioactive release during emergencies, making them a preferred long-term solution in nuclear fuel management.

Cooling Mechanisms and Performance

Dry cask storage cools spent nuclear fuel through passive air circulation, where natural convection draws ambient air over the casks to dissipate heat, enabling effective heat removal without external power. Spent fuel pools rely on active cooling systems involving circulating water pumped through heat exchangers, maintaining subcritical temperatures and removing decay heat immediately after reactor discharge. Dry cask storage offers longer-term, low-maintenance cooling with robust containment, while spent fuel pools provide rapid heat removal but demand continuous monitoring and power for circulation systems.

Storage Capacity and Scalability

Dry cask storage offers higher scalability and modular storage capacity, accommodating increasing volumes of spent nuclear fuel as pools reach their limits. Spent fuel pools have limited, fixed capacity based on pool size and design, requiring significant infrastructure expansion to increase storage. Dry cask systems enable flexible, on-site expansion without extensive modifications, making them suitable for long-term, high-capacity storage needs.

Regulatory Compliance and Licensing

Dry cask storage systems comply with stringent NRC regulations outlined in 10 CFR Part 72, requiring comprehensive safety analyses and rigorous licensing processes to ensure secure containment of spent nuclear fuel. Spent fuel pools are regulated under 10 CFR Part 50, demanding continuous monitoring, criticality safety, and water chemistry controls as part of operating licenses. Both storage methods undergo periodic inspections and must meet regulatory criteria to maintain licenses, ensuring protection of public health and the environment.

Risk Assessment: Seismic and Security Concerns

Dry cask storage demonstrates enhanced seismic resilience due to its robust, passive design and decentralized placement compared to spent fuel pools, which rely on large volumes of water and structural integrity to prevent damage. Security concerns favor dry casks as well, since they minimize centralized radioactive material, reducing vulnerability to terrorist attacks or sabotage. Comprehensive risk assessments highlight that dry cask systems mitigate potential radiological release from earthquakes or security breaches more effectively than spent fuel pools.

Long-term Sustainability and Environmental Impact

Dry cask storage offers enhanced long-term sustainability by securely containing spent nuclear fuel in robust, corrosion-resistant steel and concrete containers, minimizing radiation leakage over decades. Spent fuel pools require continuous active cooling and water treatment, posing higher risks of environmental contamination in case of system failure or leaks. The low maintenance and passive safety features of dry cask storage reduce energy consumption and environmental impact compared to the ongoing operational demands of spent fuel pools.

Economic Analysis and Implementation Challenges

Dry cask storage offers lower lifecycle costs compared to spent fuel pools due to reduced operational and maintenance expenses, making it economically favorable for long-term nuclear waste management. Implementation challenges for dry cask storage include regulatory approvals, site selection, and infrastructure development, whereas spent fuel pools require substantial upfront investment in facility construction and continuous cooling systems. Economic analysis must consider factors such as capital costs, safety upgrades, and decommissioning expenses to optimize storage strategies effectively.

Interim storage

Dry cask storage provides a safer, more durable interim storage solution for spent nuclear fuel compared to spent fuel pools by enhancing heat dissipation and reducing risks of water leaks.

Passive heat removal

Dry cask storage utilizes passive heat removal through natural convection and radiation, providing safer and more effective cooling for spent nuclear fuel compared to spent fuel pools that rely on active water circulation.

Radiological shielding

Dry cask storage provides superior radiological shielding compared to spent fuel pools by using thick steel and concrete barriers that effectively attenuate gamma and neutron radiation, ensuring enhanced protection for workers and the environment.

Criticality control

Dry cask storage enhances criticality control by using robust physical barriers and neutron-absorbing materials compared to spent fuel pools, which rely primarily on water's moderation and subcritical geometry to prevent nuclear chain reactions.

High-burnup fuel

High-burnup fuel requires dry cask storage due to increased heat generation and radiation levels that exceed spent fuel pool capacity and safety limits.

Canister integrity

Dry cask storage ensures superior canister integrity by providing robust, corrosion-resistant containment compared to the continuously submerged environment of spent fuel pools.

Pool-to-dry transfer

Pool-to-dry transfer involves moving spent nuclear fuel from underwater spent fuel pools, where it cools and shields radiation, to dry cask storage systems that provide passive air cooling and enhanced containment for long-term safety.

On-site storage pad

On-site storage pads for dry cask storage provide a robust, passive cooling system and enhanced radiation shielding compared to spent fuel pools, enabling safer long-term containment of high-level radioactive waste.

Seismic qualification

Dry cask storage systems demonstrate superior seismic qualification compared to spent fuel pools by incorporating robust structural designs and passive safety features that ensure fuel integrity during earthquakes.

Wet-to-dry transition

The wet-to-dry transition in spent nuclear fuel management involves safely transferring irradiated fuel rods from spent fuel pools to dry cask storage, reducing corrosion risks and enabling long-term, passive cooling.

dry cask storage vs spent fuel pool Infographic

njnir.com

njnir.com