High-temperature gas-cooled reactors (HTGRs) offer superior thermal efficiency and inherent safety features through their use of helium coolant and graphite moderators, enabling operation at temperatures exceeding 750degC. Small modular reactors (SMRs) emphasize compact design with scalable capacity, enhancing flexibility and reducing onsite construction time while maintaining robust safety systems. HTGRs excel in process heat applications, whereas SMRs provide versatility for power generation in remote or limited-grid environments.

Table of Comparison

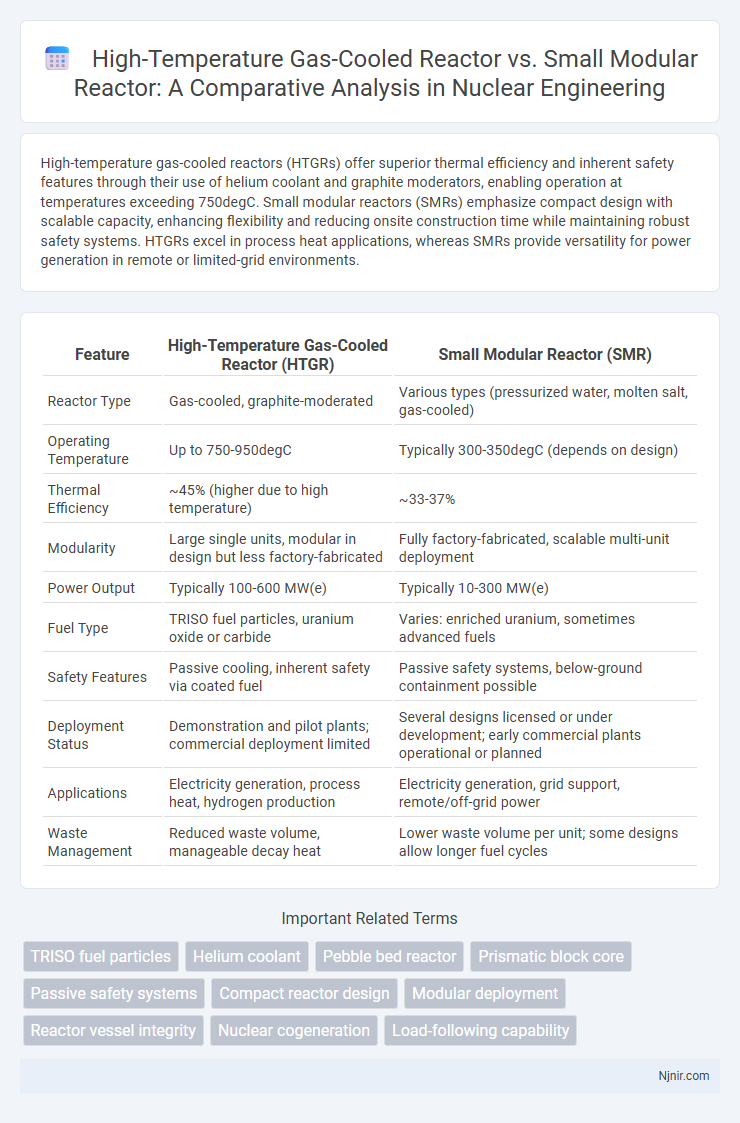

| Feature | High-Temperature Gas-Cooled Reactor (HTGR) | Small Modular Reactor (SMR) |

|---|---|---|

| Reactor Type | Gas-cooled, graphite-moderated | Various types (pressurized water, molten salt, gas-cooled) |

| Operating Temperature | Up to 750-950degC | Typically 300-350degC (depends on design) |

| Thermal Efficiency | ~45% (higher due to high temperature) | ~33-37% |

| Modularity | Large single units, modular in design but less factory-fabricated | Fully factory-fabricated, scalable multi-unit deployment |

| Power Output | Typically 100-600 MW(e) | Typically 10-300 MW(e) |

| Fuel Type | TRISO fuel particles, uranium oxide or carbide | Varies: enriched uranium, sometimes advanced fuels |

| Safety Features | Passive cooling, inherent safety via coated fuel | Passive safety systems, below-ground containment possible |

| Deployment Status | Demonstration and pilot plants; commercial deployment limited | Several designs licensed or under development; early commercial plants operational or planned |

| Applications | Electricity generation, process heat, hydrogen production | Electricity generation, grid support, remote/off-grid power |

| Waste Management | Reduced waste volume, manageable decay heat | Lower waste volume per unit; some designs allow longer fuel cycles |

Introduction to High-Temperature Gas-Cooled Reactors (HTGR) and Small Modular Reactors (SMR)

High-Temperature Gas-Cooled Reactors (HTGR) utilize helium coolant and graphite moderator to achieve outlet temperatures up to 750-950degC, enabling efficient hydrogen production and process heat applications. Small Modular Reactors (SMR) are compact nuclear systems with power outputs typically under 300 MWe, designed for enhanced safety, modular construction, and flexible deployment. Both HTGRs and SMRs focus on advanced safety features and scalability, supporting clean energy goals within diverse industrial and remote settings.

Design Principles: HTGR vs SMR Technologies

High-temperature gas-cooled reactors (HTGRs) utilize helium coolant and graphite moderators to achieve elevated outlet temperatures around 750-950degC, enhancing thermal efficiency and enabling process heat applications. Small modular reactors (SMRs) encompass various designs, including pressurized water and molten salt reactors, prioritizing compactness, modular construction, and inherent safety features that simplify operation and deployment. HTGR design emphasizes sustained high-temperature operation and fuel integrity, while SMRs focus on scalability, passive safety, and reduced capital costs through factory fabrication.

Fuel Types and Core Configurations

High-temperature gas-cooled reactors (HTGRs) utilize TRISO fuel particles embedded in graphite pebbles or blocks, enabling operation at temperatures exceeding 750degC and providing excellent fuel integrity and fission product retention. Small modular reactors (SMRs) often employ light water reactor (LWR) fuel assemblies based on low-enriched uranium, with compact core designs optimized for factory fabrication and enhanced passive safety features. HTGR cores are characterized by a graphite moderator with a prismatic or pebble-bed configuration, while SMRs feature diverse core designs, including integral pressurized water reactor (PWR) cores and fast-neutron spectrum cores, tailored for modular scalability and deployment flexibility.

Thermal Efficiency and Power Output Comparison

High-temperature gas-cooled reactors (HTGRs) achieve thermal efficiencies typically around 45% due to their elevated coolant outlet temperatures exceeding 750degC, enhancing thermodynamic performance compared to traditional reactors. Small modular reactors (SMRs) generally exhibit lower thermal efficiencies, often between 33% to 40%, owing to their compact designs and lower operating temperatures around 300degC to 350degC, which constrain efficiency but allow for flexible deployment. In terms of power output, HTGRs are designed for higher capacity, often producing 200 to 600 MW thermal power with potential for large-scale electricity generation, whereas SMRs typically range from 10 to 300 MW electric output, focusing on modular scalability and incremental capacity additions.

Safety Features and Passive Safety Systems

High-temperature gas-cooled reactors (HTGRs) utilize inert helium coolant and robust ceramic fuel coatings, enabling high thermal efficiency and strong resistance to meltdown under extreme conditions. Small modular reactors (SMRs) incorporate passive safety systems such as gravity-driven cooling and natural circulation, which operate without external power or human intervention to maintain safe temperatures. Both reactor types emphasize inherent safety, but HTGRs offer superior fuel integrity at high temperatures, while SMRs provide scalable, integrated passive safety mechanisms suitable for diverse deployment scenarios.

Modular Construction and Scalability

High-temperature gas-cooled reactors (HTGRs) leverage modular construction with pre-fabricated graphite core blocks and modular fuel assemblies, enabling efficient thermal management and safer operation at high temperatures. Small modular reactors (SMRs) emphasize factory-built modules that simplify on-site assembly, enhancing scalability by allowing sequential capacity additions tailored to demand. Both technologies benefit from modular construction, yet SMRs generally offer greater scalability flexibility through compact designs and standardized components suited for diverse energy grids.

Operational Flexibility and Load Following Capabilities

High-temperature gas-cooled reactors (HTGRs) offer enhanced operational flexibility through their ability to sustain high thermal output with rapid temperature changes, supporting efficient load following in power grids. Small modular reactors (SMRs) provide superior load-following capabilities due to their compact design and modular construction, allowing incremental power adjustments and fast ramp-up/down rates. Both technologies contribute to grid stability, but SMRs excel in scalability and quick response times, whereas HTGRs focus on maintaining high thermal efficiency during variable load conditions.

Waste Management and Environmental Impact

High-temperature gas-cooled reactors (HTGRs) generate waste with lower radioactivity and longer half-lives compared to traditional reactors, enabling more manageable long-term storage solutions. Small modular reactors (SMRs) produce less nuclear waste overall due to their smaller scale and enhanced fuel efficiency, which reduces the volume and toxicity of spent fuel. Both technologies offer reduced environmental impact by minimizing thermal pollution and enabling integration with renewable energy systems for cleaner power generation.

Economic Considerations: Capital and Operating Costs

High-temperature gas-cooled reactors (HTGRs) generally involve higher initial capital costs due to their advanced materials and safety features, but offer lower operating costs through efficient fuel use and extended fuel cycles. Small modular reactors (SMRs) feature reduced upfront capital expenditure because of factory fabrication and modular construction, enabling faster deployment and scalability, which can lead to cost savings in project timelines. Operating costs for SMRs tend to be competitive, benefiting from simplified designs and automation, whereas HTGRs may incur higher maintenance expenses related to their high-temperature components.

Future Deployment and Application Prospects

High-temperature gas-cooled reactors (HTGRs) offer exceptional thermal efficiency and inherent safety features, making them promising for hydrogen production and industrial heat applications in future energy systems. Small modular reactors (SMRs) provide flexible deployment options with scalable capacity, ideal for remote or off-grid locations and integration into existing power grids. Both technologies are poised to contribute significantly to decarbonization goals, with HTGRs excelling in high-temperature process heat markets and SMRs advancing distributed energy generation and resilience.

TRISO fuel particles

High-temperature gas-cooled reactors utilize TRISO fuel particles known for exceptional thermal stability and fission product retention, whereas small modular reactors often employ conventional fuel types with differing safety and performance characteristics.

Helium coolant

High-temperature gas-cooled reactors utilize helium coolant for superior thermal efficiency and chemical inertness, whereas small modular reactors may use various coolants, often favoring water or liquid metal for compactness and cost-effectiveness.

Pebble bed reactor

The Pebble Bed Reactor, a type of high-temperature gas-cooled reactor, offers enhanced passive safety features and high thermal efficiency compared to traditional small modular reactors, making it a promising technology for scalable, clean nuclear power generation.

Prismatic block core

The prismatic block core of high-temperature gas-cooled reactors (HTGRs) offers superior passive safety and efficient high-temperature operation compared to the compact, factory-fabricated cores of small modular reactors (SMRs), which prioritize modularity and scalability over thermal efficiency.

Passive safety systems

High-temperature gas-cooled reactors utilize advanced passive safety systems such as natural convection cooling and ceramic fuel's high-temperature tolerance, while small modular reactors often employ passive emergency core cooling and gravity-driven safety mechanisms to enhance inherent safety.

Compact reactor design

High-temperature gas-cooled reactors feature compact reactor cores with advanced helium coolant systems enabling efficient heat transfer, while small modular reactors prioritize modular, scalable designs for enhanced deployment flexibility and reduced construction times.

Modular deployment

High-temperature gas-cooled reactors enable modular deployment with enhanced safety and efficiency through scalable helium-cooled designs, while small modular reactors offer compact, factory-fabricated units optimized for rapid, flexible site assembly and grid integration.

Reactor vessel integrity

High-temperature gas-cooled reactors (HTGRs) boast superior reactor vessel integrity due to their robust graphite core and ceramic-coated fuel, enabling enhanced thermal tolerance and reduced corrosion compared to small modular reactors (SMRs) with metallic pressure vessels prone to stress and fatigue under high-temperature conditions.

Nuclear cogeneration

High-temperature gas-cooled reactors enable efficient nuclear cogeneration with higher thermal output and flexibility for hydrogen production and industrial heat applications compared to small modular reactors.

Load-following capability

High-temperature gas-cooled reactors offer robust thermal inertia for stable load-following operations, whereas small modular reactors provide enhanced operational flexibility and rapid power adjustments suited for dynamic grid demands.

high-temperature gas-cooled reactor vs small modular reactor Infographic

njnir.com

njnir.com