On-line refueling enables continuous reactor operation by replacing fuel assemblies while the reactor remains active, significantly increasing plant availability and reducing downtime compared to batch refueling, which requires a shutdown for fuel replacement. This method is particularly advantageous in heavy-water reactors where modular fuel bundles facilitate swift handling, enhancing operational efficiency and optimizing power output. Conversely, batch refueling involves periodic outages to simultaneously remove and replace multiple fuel elements, simplifying maintenance but impacting overall capacity factors and economic performance.

Table of Comparison

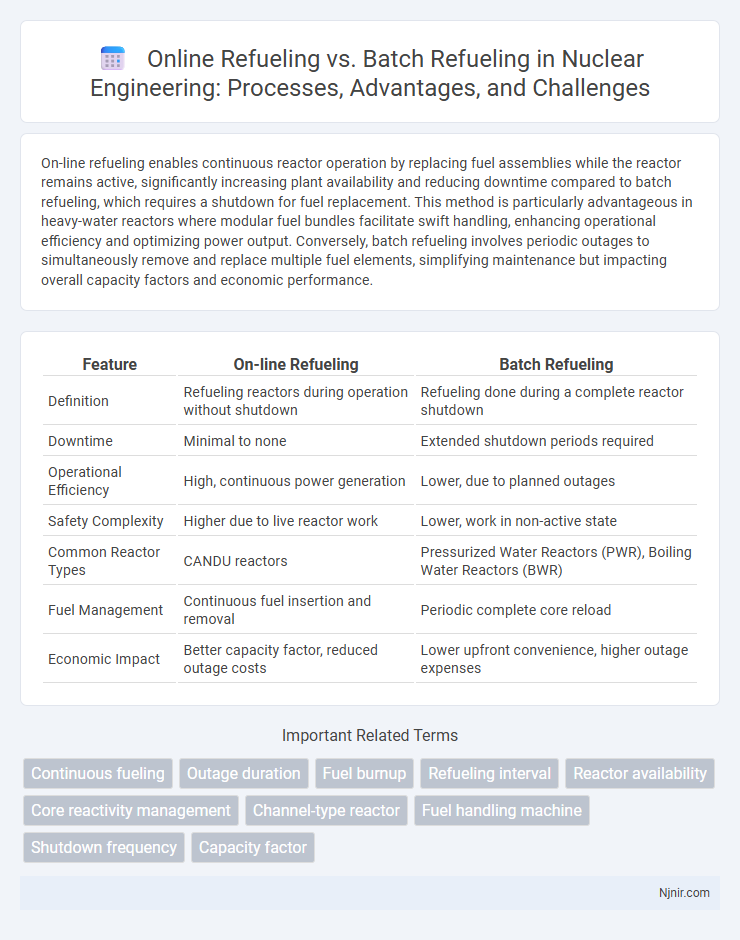

| Feature | On-line Refueling | Batch Refueling |

|---|---|---|

| Definition | Refueling reactors during operation without shutdown | Refueling done during a complete reactor shutdown |

| Downtime | Minimal to none | Extended shutdown periods required |

| Operational Efficiency | High, continuous power generation | Lower, due to planned outages |

| Safety Complexity | Higher due to live reactor work | Lower, work in non-active state |

| Common Reactor Types | CANDU reactors | Pressurized Water Reactors (PWR), Boiling Water Reactors (BWR) |

| Fuel Management | Continuous fuel insertion and removal | Periodic complete core reload |

| Economic Impact | Better capacity factor, reduced outage costs | Lower upfront convenience, higher outage expenses |

Introduction to Nuclear Reactor Refueling Methods

Online refueling allows nuclear reactors to replenish fuel without shutting down, enhancing operational efficiency and continuous power generation. In contrast, batch refueling requires a complete or partial reactor shutdown to replace fuel assemblies, often resulting in longer downtime. Choosing between these methods depends on reactor design, safety protocols, and economic considerations, impacting maintenance scheduling and overall plant performance.

Overview of On-Line Refueling Systems

On-line refueling systems enable continuous removal and replacement of nuclear fuel without shutting down the reactor, significantly enhancing operational efficiency and reactor availability. These systems employ specialized fueling machines and remote handling tools to ensure precise fuel manipulation under high radiation environments, thereby minimizing downtime. Compared to batch refueling, on-line refueling supports extended fuel cycles and improved fuel utilization by allowing incremental fuel adjustments during power operation.

Batch Refueling: Concept and Process

Batch refueling involves periodically shutting down a system or equipment to replenish fuel in a single, concentrated session. This process ensures controlled fuel management, minimizing operational disruptions by scheduling refueling during planned downtime. Batch refueling is commonly used in industries requiring precise fuel measurement and safety protocols, such as nuclear reactors and large-scale power plants.

Reactor Types Suited for On-Line Refueling

Pressurized heavy water reactors (PHWRs) and gas-cooled reactors like the Advanced Gas-cooled Reactor (AGR) are particularly suited for on-line refueling due to their modular core design, allowing continuous fuel replacement without shutdown. This refueling method enhances operational efficiency and capacity factors by minimizing downtime compared to batch refueling systems commonly used in light water reactors (LWRs). On-line refueling is optimized in reactor types with horizontal pressure tubes or graphite-moderated cores, facilitating seamless fuel handling processes.

Reactor Types Utilizing Batch Refueling

Batch refueling is predominantly utilized in reactor types such as Pressurized Water Reactors (PWRs) and Boiling Water Reactors (BWRs), where fuel assemblies are replaced periodically during scheduled outages. This method allows for detailed inspection and maintenance of the reactor core, ensuring long-term operational safety and efficiency. Unlike on-line refueling systems commonly used in CANDU reactors, batch refueling requires the reactor to be shut down, impacting overall plant availability.

Operational Efficiency: On-Line vs Batch Refueling

On-line refueling enables continuous reactor operation by allowing fuel replacement without shutdown, significantly increasing operational availability and throughput. Batch refueling requires reactor shutdown for large-scale fuel replacement, resulting in longer downtime and reduced productivity. The seamless integration of on-line refueling minimizes interruptions, optimizing overall operational efficiency in nuclear power generation.

Safety Considerations in Refueling Strategies

Online refueling enhances operational safety by minimizing reactor downtime and reducing exposure to radiation, as fuel replacement occurs without shutting down the reactor, limiting hazardous conditions. Batch refueling, while simpler, presents increased risk due to the necessity of reactor shutdowns, extended exposure to high radiation fields, and complicated handling procedures. Implementing rigorous safety protocols and leveraging automated systems in online refueling effectively mitigates potential hazards, improving overall safety in nuclear fuel management.

Economic Implications of Refueling Approaches

On-line refueling minimizes operational downtime by allowing continuous reactor operation, ultimately improving economic efficiency through increased power output and reduced revenue loss. Batch refueling requires reactor shutdown, leading to significant economic costs from interrupted electricity generation and increased maintenance expenses. Optimizing refueling schedules based on fuel cycle economics and operational priorities critically impacts overall plant profitability.

Fuel Utilization and Waste Management

Online refueling enhances fuel utilization by enabling continuous reactor operation without shutdowns, reducing unburned fuel and improving overall efficiency. Batch refueling requires reactor shutdowns, leading to underutilized fuel assemblies and increased generation of spent fuel waste. Efficient waste management is better supported by online refueling due to consistent fuel burnup and reduced volume of radioactive waste compared to batch refueling processes.

Future Trends in Nuclear Refueling Technologies

Online refueling technology allows nuclear reactors to replace fuel assemblies without shutdown, significantly enhancing operational efficiency and capacity factors compared to batch refueling, which requires reactor downtime for simultaneous fuel replacement. Emerging advancements in robotics, AI-driven diagnostics, and automated fuel handling systems are expected to accelerate the adoption of online refueling, particularly in next-generation Small Modular Reactors (SMRs) and advanced reactor designs. These trends aim to reduce refueling outages, optimize fuel utilization, and improve overall plant safety and economic performance in future nuclear power operations.

Continuous fueling

Continuous fueling in online refueling systems enhances operational efficiency by maintaining uninterrupted energy supply, reducing downtime compared to batch refueling methods.

Outage duration

Online refueling reduces outage duration significantly compared to batch refueling by allowing continuous reactor operation without shutdown.

Fuel burnup

Online refueling enables continuous operation by allowing fuel replacement without shutdown, resulting in more consistent fuel burnup rates compared to batch refueling, which causes fluctuations due to periodic shutdowns and complete core replacements.

Refueling interval

Online refueling enables continuous operation with minimal refueling intervals, significantly reducing downtime compared to the longer, scheduled intervals required for batch refueling.

Reactor availability

Online refueling significantly improves reactor availability by enabling continuous operation without shutdowns, whereas batch refueling requires reactor downtime, reducing overall operational efficiency.

Core reactivity management

Online refueling enables continuous core reactivity management by allowing real-time adjustments and maintaining optimal neutron flux, whereas batch refueling involves periodic shutdowns that cause larger reactivity swings and require conservative control strategies.

Channel-type reactor

Channel-type reactors enable continuous on-line refueling, improving operational efficiency and reducing downtime compared to conventional batch refueling methods.

Fuel handling machine

Fuel handling machines in online refueling systems enable continuous reactor operation with minimal downtime, whereas batch refueling requires periodic reactor shutdowns for fuel replacement, impacting overall efficiency.

Shutdown frequency

Online refueling significantly reduces shutdown frequency compared to batch refueling by enabling continuous reactor operation without complete fuel replacement.

Capacity factor

Online refueling enhances the capacity factor of nuclear reactors by minimizing downtime compared to batch refueling, which requires complete shutdowns for fuel replacement.

on-line refueling vs batch refueling Infographic

njnir.com

njnir.com