Molten salt reactors utilize liquid fluoride or chloride salts as both fuel solvents and coolants, offering enhanced safety due to low operating pressure and inherent negative temperature coefficients. Sodium-cooled reactors employ liquid sodium as a coolant, providing excellent thermal conductivity but presenting challenges with chemical reactivity and high operating pressure. Compared to sodium-cooled reactors, molten salt reactors allow for continuous fuel reprocessing, improved waste management, and greater fuel efficiency, making them promising candidates for sustainable nuclear energy.

Table of Comparison

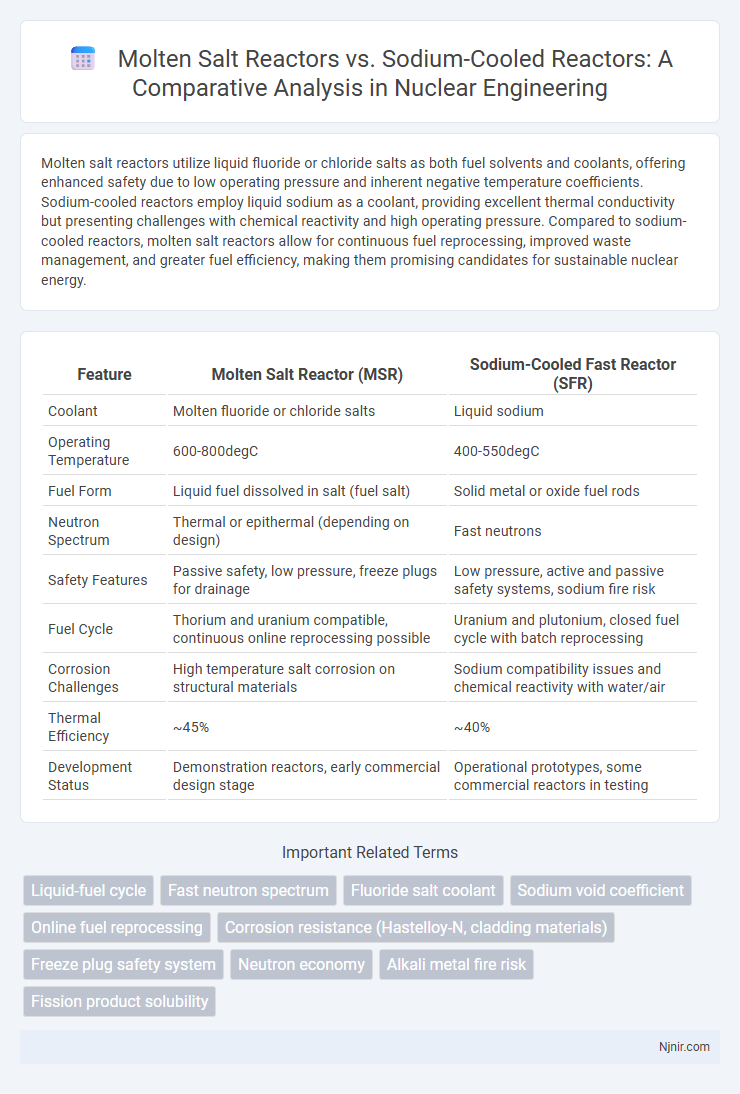

| Feature | Molten Salt Reactor (MSR) | Sodium-Cooled Fast Reactor (SFR) |

|---|---|---|

| Coolant | Molten fluoride or chloride salts | Liquid sodium |

| Operating Temperature | 600-800degC | 400-550degC |

| Fuel Form | Liquid fuel dissolved in salt (fuel salt) | Solid metal or oxide fuel rods |

| Neutron Spectrum | Thermal or epithermal (depending on design) | Fast neutrons |

| Safety Features | Passive safety, low pressure, freeze plugs for drainage | Low pressure, active and passive safety systems, sodium fire risk |

| Fuel Cycle | Thorium and uranium compatible, continuous online reprocessing possible | Uranium and plutonium, closed fuel cycle with batch reprocessing |

| Corrosion Challenges | High temperature salt corrosion on structural materials | Sodium compatibility issues and chemical reactivity with water/air |

| Thermal Efficiency | ~45% | ~40% |

| Development Status | Demonstration reactors, early commercial design stage | Operational prototypes, some commercial reactors in testing |

Introduction to Advanced Nuclear Reactor Technologies

Molten salt reactors (MSRs) utilize liquid fluoride or chloride salts as both fuel carriers and coolants, enabling high-temperature operation and inherent safety through passive heat removal. Sodium-cooled fast reactors (SFRs) employ liquid sodium as a coolant to achieve efficient heat transfer and fast neutron spectrum for effective fuel breeding and waste reduction. Both advanced nuclear technologies aim to improve sustainability, safety, and economic viability over traditional light-water reactors by enhancing fuel utilization and minimizing radioactive waste.

Principles of Molten Salt Reactors

Molten salt reactors (MSRs) operate by circulating liquid fuel mixed with molten salts, which acts as both the coolant and the fuel carrier, allowing high-temperature operation at atmospheric pressure and improved thermal efficiency compared to sodium-cooled reactors. The molten salt's chemical stability and low vapor pressure minimize the risk of high-pressure accidents, while its high heat capacity enables effective heat transfer and passive safety features. Unlike sodium-cooled reactors that rely on metallic sodium as a separate coolant, MSRs integrate fuel and coolant, enabling continuous fuel reprocessing and reducing long-lived nuclear waste.

Fundamentals of Sodium-Cooled Reactors

Sodium-cooled reactors utilize liquid sodium as a coolant, offering superior thermal conductivity and high boiling points, which enable efficient heat transfer and operation at near atmospheric pressure. Unlike molten salt reactors that use a molten salt mixture as both fuel solvent and coolant, sodium-cooled reactors separate the coolant from the fuel, typically using solid fuel rods. The fundamental advantages of sodium-cooled reactors include fast neutron spectrum capabilities, inherent safety features due to sodium's excellent heat removal properties, and proven operational performance in fast breeder reactor designs.

Coolant Properties: Molten Salt vs Sodium

Molten salt coolants exhibit high boiling points and excellent thermal stability, allowing reactors to operate at atmospheric pressure, reducing the risk of high-pressure accidents. Sodium coolant offers superior thermal conductivity and a lower melting point, facilitating efficient heat transfer but requiring inert atmosphere handling due to its high reactivity with water and air. The choice between molten salt and sodium coolants significantly influences reactor safety, efficiency, and design complexity in advanced nuclear systems.

Safety Features and Risk Profiles

Molten salt reactors (MSRs) offer enhanced safety features by operating at low pressure and utilizing chemically stable salts that solidify upon cooling, which significantly reduces the risk of pressure-driven accidents and radioactive release compared to sodium-cooled fast reactors (SFRs). Sodium-cooled reactors maintain excellent heat transfer properties but face risks such as sodium's high chemical reactivity with water and air, leading to potential fire hazards and complex emergency management. The inherent passive safety mechanisms of MSRs, including their negative temperature coefficient and delayed fission product release, provide a lower risk profile relative to SFRs, which require robust active safety systems to mitigate sodium-related risks.

Fuel Cycle and Waste Management

Molten salt reactors (MSRs) feature a fluid fuel cycle that enables continuous reprocessing and recycling of fuel, significantly reducing long-lived radioactive waste compared to sodium-cooled fast reactors (SFRs), which rely on solid fuel assemblies with batch refueling and complex off-site reprocessing. MSRs operate with online fuel salt processing that extracts fission products and manages actinides more efficiently, leading to lower radiotoxicity and reduced waste volume over the reactor lifetime. In contrast, SFRs generate higher quantities of transuranic elements requiring extensive waste conditioning and long-term geological disposal solutions.

Thermal Efficiency and Power Generation

Molten salt reactors achieve higher thermal efficiency, often exceeding 45%, due to their ability to operate at higher temperatures around 700-800degC compared to sodium-cooled reactors, which typically operate near 550-600degC with thermal efficiencies around 40%. The higher operating temperature in molten salt reactors allows for improved power generation capacity and better utilization of thermal energy within a closed fuel cycle. Sodium-cooled reactors benefit from excellent heat transfer properties of liquid sodium but face limitations in thermal efficiency and power output due to lower operational temperatures and material constraints.

Materials Compatibility and Corrosion Challenges

Molten salt reactors utilize fluoride or chloride salts, which exhibit high chemical stability and act as both fuel solvents and coolants, reducing corrosion risks compared to sodium-cooled reactors that rely on liquid sodium, a highly reactive metal prone to aggressive oxidation and embrittlement of structural alloys. Materials for molten salt reactors require advanced corrosion-resistant alloys such as Hastelloy-N capable of withstanding halide salt environments at elevated temperatures, whereas sodium-cooled reactors typically use austenitic stainless steels or ferritic-martensitic steels vulnerable to sodium corrosion and carburization. Both reactor types face challenges in managing corrosion-induced degradation, but molten salt reactors benefit from the self-healing properties of salts and lower oxygen impurity levels that mitigate corrosion processes more effectively than the highly reactive sodium coolant environment.

Economic Considerations and Deployment Potential

Molten salt reactors (MSRs) offer significant economic advantages due to their high thermal efficiency and reduced fuel costs from online refueling, potentially lowering operational expenses compared to sodium-cooled fast reactors (SFRs). SFRs face higher capital costs and maintenance challenges linked to the highly reactive nature of liquid sodium, impacting deployment timelines and overall project economics. The scalability and modular design of MSRs support faster deployment and greater flexibility in meeting diverse energy demands, enhancing their attractiveness for commercial power generation markets.

Future Prospects and Technological Advancements

Molten salt reactors (MSRs) offer promising future prospects due to their inherent safety features, high thermal efficiency, and ability to utilize thorium fuel cycles, which enhances sustainability and resource utilization. Sodium-cooled reactors (SFRs) benefit from advanced fast neutron spectrum technology, enabling efficient breeding of fissile material and reduced nuclear waste through better fuel recycling. Technological advancements in MSRs focus on corrosion-resistant materials and online fuel processing, while SFRs prioritize improved sodium coolant handling systems and enhanced passive safety mechanisms.

Liquid-fuel cycle

Molten salt reactors use a liquid fuel cycle where the fuel is dissolved in molten salt allowing continuous reprocessing and online refueling, whereas sodium-cooled reactors use a solid fuel cycle requiring batch refueling and off-line fuel handling.

Fast neutron spectrum

Molten salt reactors utilize a fast neutron spectrum with liquid fuel enabling high neutron economy and better fuel utilization, whereas sodium-cooled fast reactors operate with a solid fuel and liquid sodium coolant, providing efficient heat transfer but facing challenges with sodium's chemical reactivity.

Fluoride salt coolant

Fluoride salt coolant in molten salt reactors offers superior thermal stability, low neutron absorption, and enhanced chemical inertness compared to sodium-cooled reactors, enabling higher operating temperatures and improved safety margins.

Sodium void coefficient

Molten salt reactors typically exhibit a negative sodium void coefficient, enhancing safety by reducing reactivity if coolant sodium density decreases, whereas sodium-cooled reactors often have a positive sodium void coefficient, increasing the risk of reactivity excursions during coolant voiding events.

Online fuel reprocessing

Molten salt reactors enable continuous online fuel reprocessing by dissolving fuel in liquid salt, enhancing efficiency and reducing waste, whereas sodium-cooled reactors require offline reprocessing due to solid fuel assemblies.

Corrosion resistance (Hastelloy-N, cladding materials)

Molten salt reactors exhibit superior corrosion resistance due to the use of Hastelloy-N and fluoride salt coolant, whereas sodium-cooled reactors face greater cladding corrosion challenges with stainless steel and ferritic-martensitic alloys in liquid sodium environments.

Freeze plug safety system

The molten salt reactor's freeze plug safety system uses a passive, temperature-sensitive solid salt barrier that melts to drain fuel salt into a secure tank during overheating, offering inherently safer and more reliable emergency shutdown compared to the mechanically dependent freeze plug system in sodium-cooled reactors.

Neutron economy

Molten salt reactors achieve superior neutron economy compared to sodium-cooled reactors due to lower neutron absorption in coolant and enhanced neutron moderation, enabling improved fuel utilization and breeding potential.

Alkali metal fire risk

Molten salt reactors significantly reduce alkali metal fire risk compared to sodium-cooled reactors due to their chemically stable, high-temperature molten salts that are non-flammable, whereas sodium-cooled reactors use highly reactive liquid sodium prone to violent fires upon air or water exposure.

Fission product solubility

Molten salt reactors exhibit higher fission product solubility in their liquid fuel compared to sodium-cooled reactors, enabling efficient containment and continuous removal of fission products during operation.

molten salt reactor vs sodium-cooled reactor Infographic

njnir.com

njnir.com