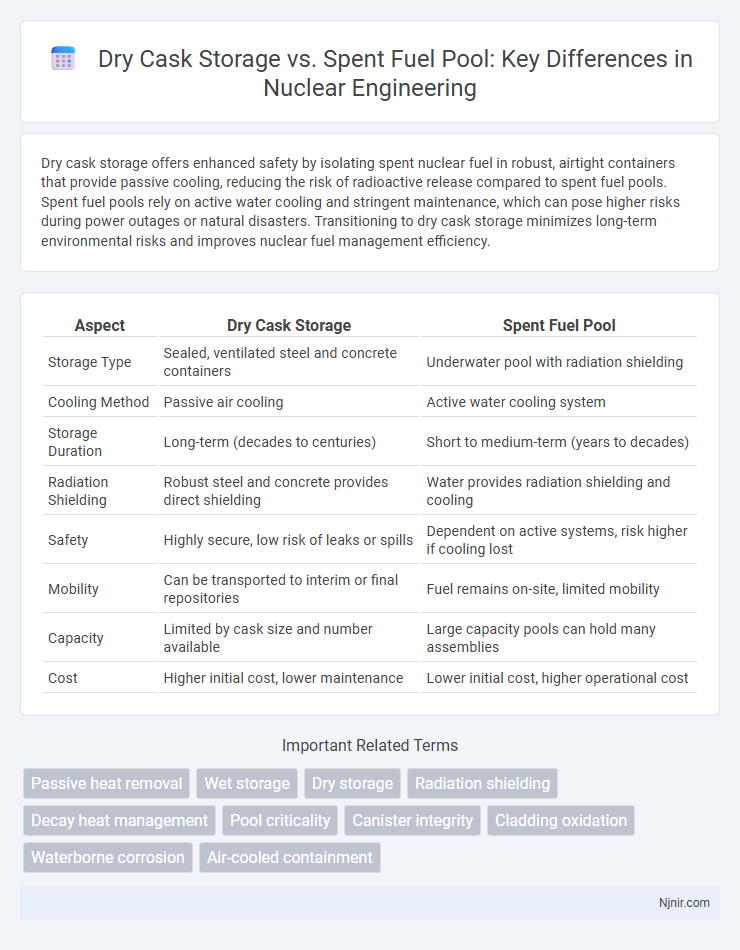

Dry cask storage offers enhanced safety by isolating spent nuclear fuel in robust, airtight containers that provide passive cooling, reducing the risk of radioactive release compared to spent fuel pools. Spent fuel pools rely on active water cooling and stringent maintenance, which can pose higher risks during power outages or natural disasters. Transitioning to dry cask storage minimizes long-term environmental risks and improves nuclear fuel management efficiency.

Table of Comparison

| Aspect | Dry Cask Storage | Spent Fuel Pool |

|---|---|---|

| Storage Type | Sealed, ventilated steel and concrete containers | Underwater pool with radiation shielding |

| Cooling Method | Passive air cooling | Active water cooling system |

| Storage Duration | Long-term (decades to centuries) | Short to medium-term (years to decades) |

| Radiation Shielding | Robust steel and concrete provides direct shielding | Water provides radiation shielding and cooling |

| Safety | Highly secure, low risk of leaks or spills | Dependent on active systems, risk higher if cooling lost |

| Mobility | Can be transported to interim or final repositories | Fuel remains on-site, limited mobility |

| Capacity | Limited by cask size and number available | Large capacity pools can hold many assemblies |

| Cost | Higher initial cost, lower maintenance | Lower initial cost, higher operational cost |

Introduction to Spent Nuclear Fuel Management

Spent nuclear fuel management involves securely storing used reactor fuel to prevent radiation release and environmental contamination. Dry cask storage uses robust steel and concrete containers for cooled spent fuel, offering high safety and passive cooling, while spent fuel pools are large water-filled basins that provide initial cooling and radiation shielding for recently discharged fuel. Selecting between dry cask and pool storage depends on reactor history, fuel cooling time, capacity, and long-term safety regulations.

Overview of Spent Fuel Pool Storage

Spent fuel pools are deep water pools used to cool and store used nuclear fuel assemblies immediately after removal from the reactor core, leveraging water's high heat capacity and radiation shielding properties. Pools typically measure several meters in depth with racks designed to hold thousands of assemblies, maintaining water circulation to manage decay heat and prevent overheating. This wet storage method allows for effective heat dissipation and radiation protection during the initial cooling period before fuel transfer to dry cask storage.

Overview of Dry Cask Storage Technology

Dry cask storage technology involves placing spent nuclear fuel in robust steel and concrete containers designed to provide passive cooling and radiation shielding without relying on active water circulation. These casks offer a safer alternative to spent fuel pools by reducing the risk of water leaks and enhancing long-term storage stability, particularly after fuel has cooled sufficiently in pools for several years. The technology supports on-site interim storage, facilitating secure management of radioactive waste while awaiting final disposal solutions.

Safety Considerations: Dry Cask vs Spent Fuel Pool

Dry cask storage offers enhanced safety by isolating spent nuclear fuel in robust, airtight steel and concrete containers that provide passive cooling and protection from external hazards. Spent fuel pools rely on active water cooling systems to dissipate heat, which require continuous power and maintenance, posing risks during power outages or system failures. Regulatory assessments highlight dry cask storage's superior resilience against seismic events and terrorist attacks compared to the more vulnerable spent fuel pools.

Storage Capacity and Scalability

Dry cask storage offers higher scalability and modular expansion options compared to spent fuel pools, allowing nuclear facilities to increase storage capacity incrementally without extensive infrastructure modifications. Spent fuel pools, limited by their physical size and regulatory requirements, face constraints in expanding storage capacity, often necessitating complex and costly construction projects. The dry cask method efficiently accommodates growing amounts of spent nuclear fuel through stacked, secure containers, enhancing flexibility in long-term waste management.

Cooling Methods and Efficiency

Dry cask storage uses passive air cooling, where natural convection circulates air through the cask to dissipate heat, offering reliable and low-maintenance cooling for spent nuclear fuel. Spent fuel pools rely on active water cooling systems that circulate water to absorb and remove decay heat from fuel assemblies, requiring continuous power and monitoring to maintain efficiency. While wet storage provides higher initial cooling capacity, dry casks offer efficient long-term cooling with reduced operational complexity and lower risk of heat removal failure.

Environmental and Radiation Protection

Dry cask storage offers enhanced environmental and radiation protection by providing robust shielding that minimizes radiation release and reduces the risk of contamination compared to spent fuel pools. Spent fuel pools rely on water as a radiation barrier, which requires continuous cooling and carries a higher risk of radioactive material release during leaks or accidents. Dry casks, constructed from steel and concrete, ensure long-term containment and passive safety, significantly lowering environmental exposure to radiation.

Long-term Storage and Transportation

Dry cask storage offers enhanced safety and durability for long-term storage of spent nuclear fuel by encasing it in robust steel and concrete containers that prevent radiation leakage and resist environmental hazards. Spent fuel pools, while effective for initial cooling and storage, require continuous active cooling systems and extensive maintenance, posing higher risks over extended periods. For transportation, dry casks provide secure, sealed units that facilitate safer handling and compliance with regulatory standards during transit compared to the more vulnerable, water-cooled spent fuel assemblies.

Regulatory Standards and Compliance

Regulatory standards for dry cask storage and spent fuel pools are established by the Nuclear Regulatory Commission (NRC) to ensure safe containment of radioactive materials. Dry cask systems must comply with strict criteria for structural integrity, radiation shielding, and thermal performance under normal and accident conditions, as outlined in 10 CFR Part 72. Spent fuel pools are regulated under 10 CFR Part 50, requiring continuous monitoring, proper water chemistry, and redundancy in cooling systems to maintain safe storage environments and prevent radiation release.

Cost Analysis: Dry Cask vs Spent Fuel Pool

Dry cask storage involves higher initial capital costs due to manufacturing and site preparation but offers lower long-term operational expenses compared to spent fuel pools, which require continuous maintenance, security, and active cooling systems. The passive cooling nature of dry casks reduces energy consumption and staffing needs, resulting in significant cost savings over extended storage periods. Cost analyses consistently show that, beyond a few years, dry cask storage is more economical, especially for long-term or interim spent nuclear fuel management.

Passive heat removal

Dry cask storage uses passive heat removal through natural convection and radiation, enhancing safety compared to spent fuel pools that rely more on active cooling systems.

Wet storage

Spent fuel pools provide wet storage by submerging radioactive fuel assemblies in water, which cools the fuel and shields radiation more effectively than dry cask storage.

Dry storage

Dry storage offers enhanced safety by securely containing spent nuclear fuel in robust, airtight casks that prevent radiation leakage and withstand extreme environmental conditions compared to spent fuel pools.

Radiation shielding

Dry cask storage provides superior radiation shielding compared to spent fuel pools by utilizing thick concrete and steel barriers that effectively reduce gamma and neutron radiation exposure.

Decay heat management

Dry cask storage provides passive decay heat management through natural convection and radiation, while spent fuel pools rely on active cooling systems to dissipate heat from spent nuclear fuel.

Pool criticality

Spent fuel pools maintain subcriticality through geometry, neutron-absorbing materials, and continuous cooling, whereas dry casks rely on robust shielding and geometrical spacing to ensure passive criticality safety.

Canister integrity

Dry cask storage maintains superior canister integrity compared to spent fuel pools by minimizing corrosion risks through robust, sealed, and passive cooling systems.

Cladding oxidation

Cladding oxidation occurs at a significantly reduced rate in dry cask storage compared to spent fuel pools due to lower moisture exposure and improved passive cooling conditions.

Waterborne corrosion

Dry cask storage significantly reduces waterborne corrosion risks compared to spent fuel pools by minimizing prolonged fuel rod exposure to water.

Air-cooled containment

Dry casks provide air-cooled containment for spent nuclear fuel, offering enhanced passive heat dissipation and safety compared to water-based spent fuel pools.

dry cask vs spent fuel pool Infographic

njnir.com

njnir.com