Small modular reactors (SMRs) offer enhanced safety features and flexibility compared to traditional large-scale nuclear reactors by utilizing advanced passive safety systems and modular construction techniques. SMRs require less initial capital investment and can be deployed incrementally, making them ideal for remote locations and smaller grids while reducing construction times and financial risk. The compact design of SMRs allows for easier integration with renewable energy sources, supporting a more resilient and scalable low-carbon energy infrastructure.

Table of Comparison

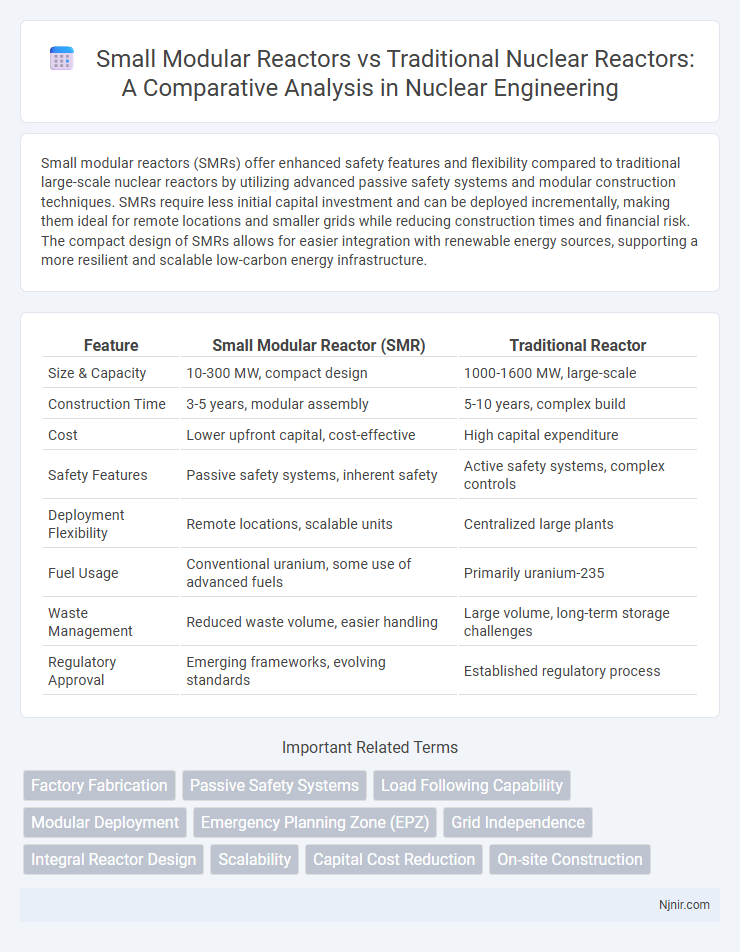

| Feature | Small Modular Reactor (SMR) | Traditional Reactor |

|---|---|---|

| Size & Capacity | 10-300 MW, compact design | 1000-1600 MW, large-scale |

| Construction Time | 3-5 years, modular assembly | 5-10 years, complex build |

| Cost | Lower upfront capital, cost-effective | High capital expenditure |

| Safety Features | Passive safety systems, inherent safety | Active safety systems, complex controls |

| Deployment Flexibility | Remote locations, scalable units | Centralized large plants |

| Fuel Usage | Conventional uranium, some use of advanced fuels | Primarily uranium-235 |

| Waste Management | Reduced waste volume, easier handling | Large volume, long-term storage challenges |

| Regulatory Approval | Emerging frameworks, evolving standards | Established regulatory process |

Overview of Small Modular Reactors (SMRs) and Traditional Reactors

Small Modular Reactors (SMRs) are compact nuclear reactors with power outputs typically below 300 MWe, designed for modular construction and enhanced safety features compared to traditional reactors, which usually exceed 1000 MWe. SMRs offer flexible deployment options, shorter construction timelines, and reduced initial capital costs, contrasting with the large-scale, capital-intensive nature of conventional reactors such as Pressurized Water Reactors (PWRs) and Boiling Water Reactors (BWRs). Traditional reactors provide high power output suited for large grids but involve complex infrastructure, while SMRs aim to complement or replace these plants by enabling scalable, site-adaptable nuclear power generation.

Design Differences: SMRs vs. Conventional Nuclear Reactors

Small modular reactors (SMRs) feature compact, factory-fabricated components designed for enhanced safety and scalability compared to traditional nuclear reactors that rely on large, site-built structures. SMRs utilize passive safety systems and modular designs that allow incremental power addition, whereas conventional reactors operate as single, large units with active safety mechanisms. The modular approach of SMRs reduces construction time and capital costs, contrasting with the lengthy and expensive build process typical of conventional nuclear plants.

Safety Features and Risk Assessment

Small modular reactors (SMRs) incorporate advanced passive safety systems that reduce reliance on active controls and human intervention, significantly minimizing the risk of accidents compared to traditional large reactors. Their compact design facilitates enhanced containment integrity and core cooling capabilities, allowing for quicker dissipation of heat and prevention of meltdown scenarios. Risk assessments highlight SMRs' lower source term release and modular scalability as critical factors in reducing environmental impact and improving emergency response effectiveness.

Cost and Economic Viability Comparison

Small modular reactors (SMRs) offer a significant cost advantage over traditional reactors due to their modular design, which reduces initial capital investment and construction time, lowering financial risk. SMRs enable scalable deployment with factory fabrication, improving quality control and reducing on-site labor expenses, enhancing overall economic viability. While traditional reactors benefit from economies of scale, their larger upfront costs and longer construction periods often result in higher financial exposure and delayed return on investment compared to SMRs.

Deployment Flexibility and Site Requirements

Small modular reactors (SMRs) offer enhanced deployment flexibility compared to traditional reactors due to their compact size and modular design, allowing for incremental capacity additions and easier transportation to remote or constrained sites. Traditional reactors require extensive infrastructure, large land areas, and long construction times, limiting site selection and resulting in higher upfront investment risks. SMRs' reduced site requirements enable installation in diverse locations, including near existing energy grids or industrial facilities, facilitating quicker project timelines and lower overall environmental impact.

Regulatory and Licensing Considerations

Small modular reactors (SMRs) benefit from streamlined regulatory frameworks due to their reduced size and enhanced safety features, facilitating faster licensing compared to traditional large reactors. Regulatory bodies emphasize standardized designs for SMRs, enabling multiple units of the same model to be licensed more efficiently and reducing duplicative assessments. Traditional reactors face extensive licensing challenges stemming from their complex systems, larger scale, and site-specific safety evaluations, often resulting in prolonged approval timelines.

Fuel Usage and Waste Management

Small modular reactors (SMRs) use fuel more efficiently than traditional reactors by operating at higher burnup levels, which reduces the amount of nuclear waste generated per unit of energy produced. SMRs often utilize advanced fuel designs and can accommodate alternative fuel cycles, including thorium and mixed oxide fuels, enhancing resource utilization. Waste management is streamlined due to smaller core sizes and modular replacement strategies, enabling easier handling, storage, and potential recycling of spent fuel compared to large-scale traditional reactors.

Scalability and Modular Construction Benefits

Small modular reactors (SMRs) offer enhanced scalability by allowing incremental capacity additions tailored to energy demand, unlike traditional reactors which require large, single-unit construction. Modular construction techniques of SMRs reduce onsite assembly time and costs, improving quality control through factory fabrication of standardized components. These benefits enable faster deployment, flexible grid integration, and increased economic viability in diverse energy markets.

Environmental Impact and Carbon Footprint

Small modular reactors (SMRs) produce significantly lower carbon footprints compared to traditional nuclear reactors due to their smaller size and enhanced efficiency in fuel use. SMRs generate less radioactive waste and have reduced land use, minimizing environmental disruption and potential contamination risks. Their modular construction also allows for faster deployment and scalability, supporting a quicker transition to low-carbon energy systems.

Future Outlook: Advancements and Market Potential

Small modular reactors (SMRs) offer significant advancements in nuclear technology, including enhanced safety features, reduced construction times, and scalable power output, positioning them as a key player in the future energy market. Market potential for SMRs is substantial, driven by growing demand for low-carbon energy solutions and flexible deployment in remote or smaller grid locations. Ongoing innovation and regulatory support are expected to accelerate SMR commercialization, potentially reshaping the global nuclear energy landscape.

Factory Fabrication

Small modular reactors (SMRs) benefit from factory fabrication by enabling standardized, high-quality production with reduced construction time and cost compared to traditional reactors built on-site.

Passive Safety Systems

Small modular reactors utilize advanced passive safety systems that operate without external power or human intervention, enhancing safety and reliability compared to traditional reactors reliant on active safety mechanisms.

Load Following Capability

Small modular reactors offer superior load following capability compared to traditional reactors due to their advanced control systems and flexible operation, enabling more efficient integration with variable renewable energy sources.

Modular Deployment

Small modular reactors enable flexible, scalable deployment with reduced construction times compared to large, traditional nuclear reactors.

Emergency Planning Zone (EPZ)

Small modular reactors (SMRs) have significantly smaller Emergency Planning Zones (EPZs) than traditional reactors due to their advanced safety features and reduced radioactive inventory.

Grid Independence

Small modular reactors (SMRs) enhance grid independence by providing scalable, distributed power generation with lower startup costs and increased flexibility compared to traditional large-scale nuclear reactors.

Integral Reactor Design

Small modular reactors feature an integral reactor design that combines the core, steam generator, and pressurizer within a single pressure vessel, enhancing safety and compactness compared to traditional reactors that have separate large components.

Scalability

Small modular reactors offer enhanced scalability by allowing incremental capacity additions compared to the fixed, large-scale output of traditional nuclear reactors.

Capital Cost Reduction

Small modular reactors reduce capital costs by enabling factory fabrication, standardized designs, and incremental capacity additions compared to traditional large-scale nuclear reactors.

On-site Construction

Small modular reactors significantly reduce on-site construction time and complexity compared to traditional reactors by utilizing factory-fabricated modules assembled quickly on-site.

small modular reactor vs traditional reactor Infographic

njnir.com

njnir.com