Single-loop reactor configurations integrate primary coolant circulation within one continuous system, offering simplified design and reduced construction costs. Dual-loop reactors separate the primary and secondary coolant circuits, enhancing safety by isolating radioactive materials and enabling higher operating pressures and temperatures. This configuration improves thermal efficiency and allows for easier maintenance while minimizing contamination risks.

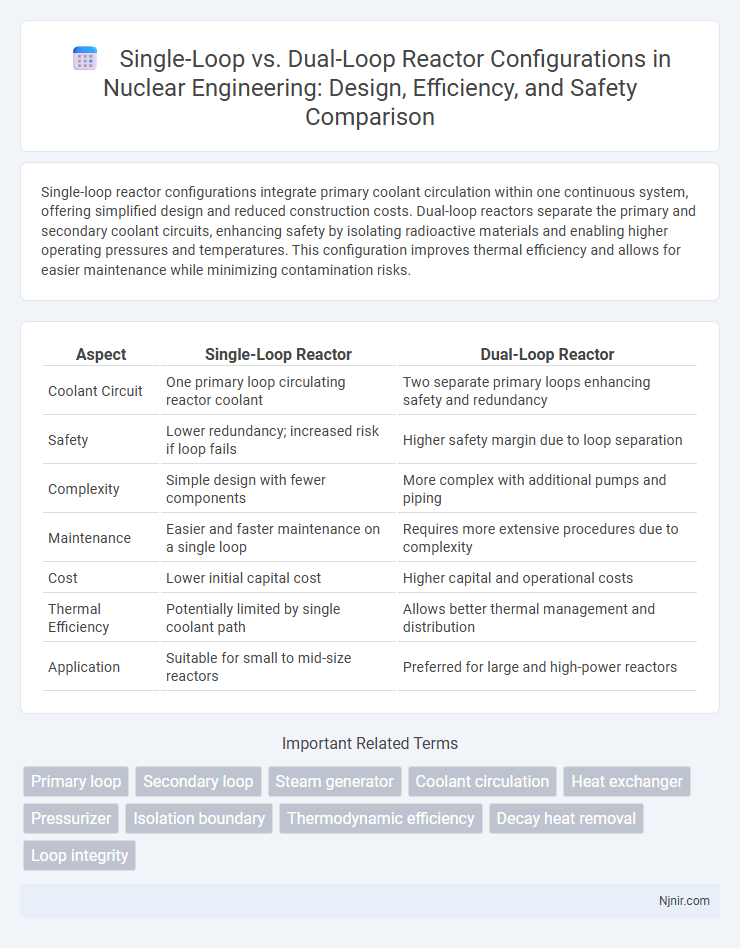

Table of Comparison

| Aspect | Single-Loop Reactor | Dual-Loop Reactor |

|---|---|---|

| Coolant Circuit | One primary loop circulating reactor coolant | Two separate primary loops enhancing safety and redundancy |

| Safety | Lower redundancy; increased risk if loop fails | Higher safety margin due to loop separation |

| Complexity | Simple design with fewer components | More complex with additional pumps and piping |

| Maintenance | Easier and faster maintenance on a single loop | Requires more extensive procedures due to complexity |

| Cost | Lower initial capital cost | Higher capital and operational costs |

| Thermal Efficiency | Potentially limited by single coolant path | Allows better thermal management and distribution |

| Application | Suitable for small to mid-size reactors | Preferred for large and high-power reactors |

Overview of Reactor Loop Configurations

Single-loop reactor configurations circulate coolant through one primary loop, directly transferring heat from the reactor core to the steam generator or heat exchanger. Dual-loop systems incorporate separate primary and secondary loops, enhancing safety by isolating the radioactive reactor coolant from the steam generator loop. These differences impact thermal efficiency, operational complexity, and maintenance requirements in nuclear reactor designs.

Fundamental Principles: Single-Loop vs Dual-Loop

Single-loop reactor configurations circulate the coolant or working fluid through one continuous path, simplifying heat exchange and control by maintaining a uniform temperature gradient. Dual-loop reactors separate the primary and secondary circuits, enhancing safety and efficiency by isolating the radioactive primary coolant from the secondary loop, often used in pressurized water reactors (PWRs) to optimize thermal performance and reduce contamination risks. The fundamental difference lies in the dual-loop's ability to manage higher pressure and temperature differentials, providing safer, more reliable heat transfer compared to the simpler, more cost-effective single-loop design.

Thermal Efficiency Considerations

Single-loop reactor configurations typically exhibit lower thermal efficiency due to limited heat transfer surfaces and simpler coolant flow paths, resulting in higher thermal losses. Dual-loop reactors enhance thermal efficiency by incorporating an intermediate loop that reduces the risk of radioactive contamination while optimizing heat exchange between primary and secondary coolants. The staged heat transfer in dual-loop systems allows for better temperature gradients and improved energy conversion efficiency compared to single-loop designs.

Safety and Reliability Aspects

Single-loop reactor configurations offer simpler designs that enhance reliability by reducing potential failure points and easing maintenance procedures. Dual-loop reactors incorporate an additional heat exchange loop, increasing safety through improved thermal isolation between the reactor core and the steam generator, which minimizes the risk of radioactive contamination. The redundancy in dual-loop systems also contributes to higher reliability by enabling continued operation or safer shutdowns in case of loop failure.

Cost Analysis and Economic Impact

Single-loop reactor configurations typically incur lower initial capital costs due to simpler design and reduced material requirements, making them economically attractive for small to medium-scale operations. Dual-loop systems, though involving higher upfront investment and maintenance costs, offer enhanced operational flexibility and improved heat recovery efficiency, leading to significant long-term savings in energy consumption and processing throughput. Economic impact assessments show that dual-loop reactors provide better return on investment in large-scale, continuous production settings by optimizing resource utilization and reducing downtime.

Maintenance and Operational Complexity

Single-loop reactor configurations typically offer simpler maintenance procedures due to fewer components and straightforward heat exchange pathways, reducing downtime and operational complexity. Dual-loop reactors involve more intricate systems with separate primary and secondary loops, which can increase maintenance tasks and the need for specialized operational expertise. However, dual-loop designs enhance safety and operational flexibility despite the added complexity.

Application Suitability in Power Generation

Single-loop reactor configurations are suitable for smaller-scale power generation plants due to their simpler design and lower construction costs, making them ideal for regions with limited grid demand. Dual-loop reactors provide enhanced safety and higher thermal efficiency, supporting larger power outputs often required in utility-scale power plants. The choice between these configurations depends on the balance between economic feasibility and the desired power capacity in the specific power generation application.

Material Challenges and Corrosion Management

Single-loop reactor configurations face significant material challenges due to higher temperature and pressure gradients within a single coolant path, increasing susceptibility to stress corrosion cracking and generalized corrosion in critical components like piping and heat exchangers. Dual-loop reactors separate the primary and secondary coolant circuits, reducing direct exposure of the turbine and secondary system materials to radioactive and chemically aggressive primary coolant, thereby enhancing corrosion resistance and simplifying maintenance. Effective corrosion management in both systems requires selecting advanced alloys, implementing rigorous water chemistry control protocols, and employing real-time monitoring technologies to mitigate degradation and extend reactor component life.

Recent Advancements and Case Studies

Recent advancements in single-loop and dual-loop reactor configurations have enhanced catalytic efficiency and process stability in chemical manufacturing. Case studies in petrochemical refining demonstrate that dual-loop reactors significantly improve reaction selectivity and yield by allowing independent temperature and pressure control in each loop. Innovations in materials and sensor integration further optimize single-loop systems, reducing operational costs while maintaining throughput in pharmaceutical production.

Future Trends in Reactor Loop Design

Future trends in reactor loop design emphasize enhancing thermal efficiency and safety by integrating advanced dual-loop configurations that separate primary coolant from secondary systems, reducing contamination risks. Innovations include optimizing coolant flow dynamics and incorporating real-time monitoring sensors to detect anomalies promptly. Research also focuses on modular reactor loops enabling scalable and adaptable deployment for various power generation needs and industrial applications.

Primary loop

The primary loop in single-loop reactor configurations circulates coolant directly through the reactor core, whereas dual-loop reactors use separate primary and secondary loops to enhance safety and thermal efficiency.

Secondary loop

The secondary loop in dual-loop reactor configurations enhances heat transfer efficiency and operational safety by isolating radioactive coolant from turbines, unlike single-loop systems where reactor coolant directly drives the turbine.

Steam generator

Dual-loop reactor configuration enhances steam generator efficiency and safety by isolating radioactive primary coolant from the secondary steam circuit, whereas single-loop systems combine these functions, increasing contamination risk and operational complexity.

Coolant circulation

Single-loop reactor configurations utilize a single coolant loop to transfer heat from the reactor core, while dual-loop reactors employ two separate coolant circuits to enhance heat transfer efficiency and improve safety through isolation.

Heat exchanger

Dual-loop reactor configurations enhance heat exchanger efficiency by separating reactive zones and enabling precise thermal management, whereas single-loop systems rely on a single heat exchanger stream, limiting temperature control and heat recovery.

Pressurizer

Dual-loop reactor configurations enhance pressurizer performance by isolating steam generation, improving pressure control stability compared to single-loop reactors.

Isolation boundary

Dual-loop reactor configurations enhance isolation boundary integrity by physically separating the primary and secondary coolant loops, reducing contamination risk compared to single-loop designs.

Thermodynamic efficiency

Dual-loop reactor configurations typically achieve higher thermodynamic efficiency than single-loop systems by optimizing heat recovery and reducing energy losses.

Decay heat removal

Dual-loop reactor configurations enhance decay heat removal efficiency by providing redundant coolant pathways, reducing the risk of overheating compared to single-loop systems.

Loop integrity

Dual-loop reactor configurations enhance loop integrity by isolating the primary and secondary loops, reducing contamination risk and improving maintenance safety compared to single-loop systems.

single-loop vs dual-loop reactor configuration Infographic

njnir.com

njnir.com