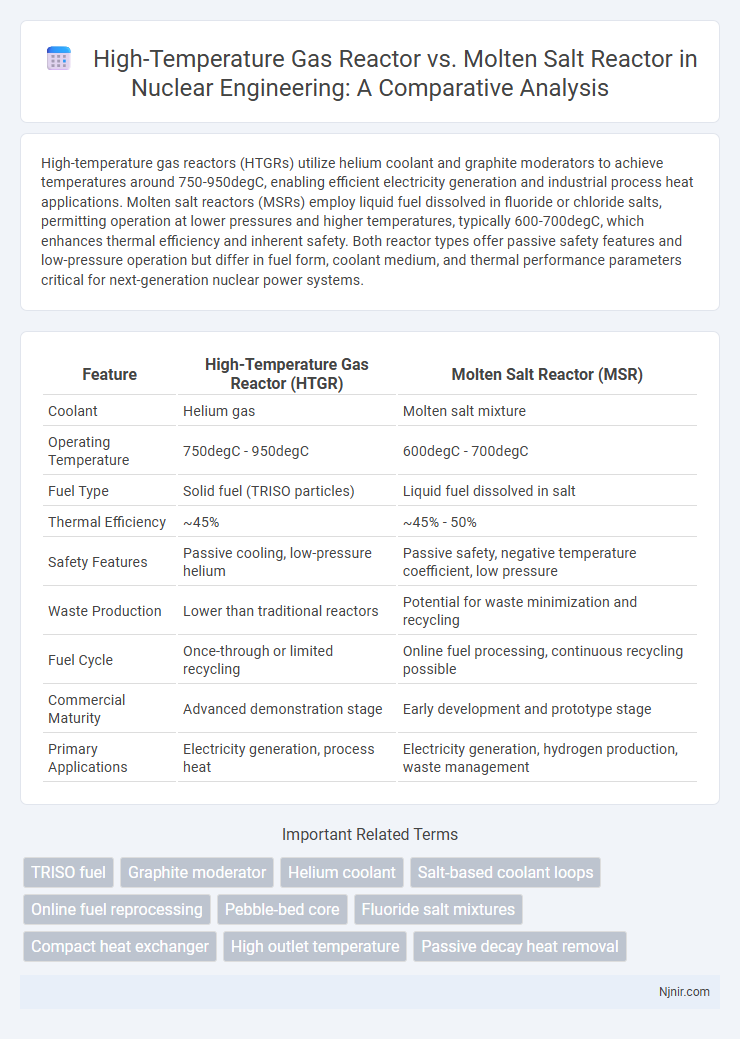

High-temperature gas reactors (HTGRs) utilize helium coolant and graphite moderators to achieve temperatures around 750-950degC, enabling efficient electricity generation and industrial process heat applications. Molten salt reactors (MSRs) employ liquid fuel dissolved in fluoride or chloride salts, permitting operation at lower pressures and higher temperatures, typically 600-700degC, which enhances thermal efficiency and inherent safety. Both reactor types offer passive safety features and low-pressure operation but differ in fuel form, coolant medium, and thermal performance parameters critical for next-generation nuclear power systems.

Table of Comparison

| Feature | High-Temperature Gas Reactor (HTGR) | Molten Salt Reactor (MSR) |

|---|---|---|

| Coolant | Helium gas | Molten salt mixture |

| Operating Temperature | 750degC - 950degC | 600degC - 700degC |

| Fuel Type | Solid fuel (TRISO particles) | Liquid fuel dissolved in salt |

| Thermal Efficiency | ~45% | ~45% - 50% |

| Safety Features | Passive cooling, low-pressure helium | Passive safety, negative temperature coefficient, low pressure |

| Waste Production | Lower than traditional reactors | Potential for waste minimization and recycling |

| Fuel Cycle | Once-through or limited recycling | Online fuel processing, continuous recycling possible |

| Commercial Maturity | Advanced demonstration stage | Early development and prototype stage |

| Primary Applications | Electricity generation, process heat | Electricity generation, hydrogen production, waste management |

Introduction to Advanced Nuclear Reactor Technologies

High-temperature gas reactors utilize helium as a coolant to achieve temperatures exceeding 750degC, enhancing thermal efficiency and hydrogen production potential. Molten salt reactors operate with liquid fuel dissolved in molten fluoride or chloride salts, allowing for inherent safety features and continuous fission product removal. Both technologies represent advanced nuclear reactor innovations aiming to improve safety, efficiency, and waste management in future energy systems.

Fundamental Designs: High-Temperature Gas Reactors (HTGR) and Molten Salt Reactors (MSR)

High-Temperature Gas Reactors (HTGR) utilize graphite-moderated cores with helium coolant, operating at temperatures up to 750-950degC to enable high thermal efficiency and robust safety features through passive cooling. Molten Salt Reactors (MSR) employ liquid fuel dissolved in molten fluoride or chloride salts, allowing for continuous fuel reprocessing and operation at atmospheric pressure with temperatures ranging from 600 to 800degC. HTGR's solid fuel particles embedded in graphite and MSR's fluid fuel design fundamentally differ in neutron moderation, heat transfer, and adaptability for waste management and fuel cycles.

Fuel Types and Reactor Core Configurations

High-temperature gas reactors (HTGRs) primarily utilize tri-structural isotropic (TRISO) coated particle fuel embedded in graphite pebbles or prismatic blocks, enabling excellent fission product retention and high-temperature operation up to 750-950degC. Molten salt reactors (MSRs) use liquid fuel mixtures, typically uranium or thorium dissolved in fluoride or chloride salts, allowing continuous fuel reprocessing and online refueling with operating temperatures around 550-700degC. The HTGR core consists of a solid graphite moderator with fixed fuel arrangements, while MSRs feature a fluid fuel configuration where the reactor core is a circulating molten salt, eliminating the need for conventional solid fuel elements.

Coolant Selection and Thermal Efficiency

High-temperature gas reactors (HTGRs) utilize helium as a coolant, providing excellent chemical inertness and high thermal conductivity, which allows operation at temperatures exceeding 750degC, enhancing thermal efficiency up to 45%. Molten salt reactors (MSRs) employ liquid salts like fluoride- or chloride-based mixtures as coolant, enabling even higher operating temperatures around 700-900degC while offering superior heat transfer and inherent safety features. The choice of coolant significantly impacts thermal efficiency, with MSRs potentially reaching efficiencies above 50% due to their capacity for continuous fuel processing and higher temperature tolerance.

Safety Features and Intrinsic Safety Mechanisms

High-temperature gas reactors (HTGRs) utilize helium coolant with low neutron absorption and high thermal conductivity, enhancing passive heat removal and reducing meltdown risk through ceramic-coated fuel particles that retain fission products at elevated temperatures. Molten salt reactors (MSRs) employ liquid fuel dissolved in molten salt, enabling continuous reprocessing and removal of fission products, which intrinsically limits radioactive buildup and increases safety margins by operating at low pressure and high heat capacity. Both reactor types feature inherent safety mechanisms such as negative temperature coefficients and passive decay heat removal, but MSRs offer superior safety through online fuel processing and low-pressure operation, minimizing the risk of large-scale release of radioactivity.

Waste Management and Proliferation Resistance

High-temperature gas reactors (HTGRs) produce solid graphite-based fuel that encapsulates fission products, facilitating easier containment and long-term storage, whereas molten salt reactors (MSRs) continuously reprocess liquid fuel, significantly reducing waste volume and radiotoxicity. MSRs offer enhanced proliferation resistance by enabling real-time removal of fissile materials and fission products, complicating diversion attempts, while HTGRs rely on robust fuel pebble designs that limit access to nuclear material. Both reactor types improve waste management compared to traditional reactors, but MSRs provide superior efficiency in minimizing long-lived radioactive waste and enhancing safeguards against nuclear proliferation.

Operational Flexibility and Load-Following Capabilities

High-temperature gas reactors (HTGRs) offer excellent operational flexibility through their strong negative temperature coefficients and stable coolant properties, allowing for rapid power adjustments and efficient load following. Molten salt reactors (MSRs) provide inherently load-following capabilities due to their liquid fuel form and online reprocessing, enabling continuous operation with minimal thermal stress and swift response to grid demand changes. Both reactor types support flexible power generation, but MSRs excel in dynamic load regulation owing to their unique fuel circulation and thermal inertia characteristics.

Materials Challenges and Corrosion Resistance

High-temperature gas reactors (HTGRs) face significant materials challenges due to extreme temperatures exceeding 750degC, requiring advanced graphite and silicon carbide composites that maintain structural integrity while resisting irradiation damage. Molten salt reactors (MSRs) encounter corrosion resistance issues primarily from the aggressive fluoride or chloride salt environments, demanding corrosion-resistant alloys such as Hastelloy-N and innovative coatings to prevent material degradation. Both reactor types require ongoing development in high-performance materials to ensure long-term operational stability and safety under harsh chemical and thermal conditions.

Economic Considerations and Deployment Scalability

High-temperature gas reactors (HTGRs) benefit from proven modular designs that reduce upfront capital costs and facilitate incremental capacity expansion, enhancing deployment scalability in nuclear energy markets. Molten salt reactors (MSRs) offer potential economic advantages through high fuel utilization and passive safety features, which can lower operational costs and waste management expenses over the reactor lifecycle. However, MSRs face regulatory and technological uncertainties that may limit near-term commercialization and large-scale deployment compared to the more mature HTGR technology.

Future Prospects and Commercialization Pathways

High-temperature gas reactors (HTGRs) offer robust safety features and high thermal efficiency, making them suitable for hydrogen production and process heat applications within the next decade. Molten salt reactors (MSRs) present advantages in fuel utilization and waste reduction, with ongoing research targeting scalable pilot projects for commercialization by the 2030s. Both technologies face regulatory challenges and require significant investment in infrastructure, but HTGRs benefit from more mature licensing frameworks while MSRs rely on breakthroughs in materials science and fuel cycle management to accelerate market entry.

TRISO fuel

High-temperature gas reactors utilize TRISO fuel particles encased in robust ceramic coatings enabling operation at temperatures exceeding 750degC with high fission product retention, while molten salt reactors often favor liquid fuel but can integrate TRISO fuel to enhance safety and corrosion resistance in molten salt environments.

Graphite moderator

High-temperature gas reactors use graphite moderators to enhance neutron economy and thermal conductivity, while molten salt reactors rely on graphite moderators to maintain structural integrity and optimize neutron moderation in a liquid fuel environment.

Helium coolant

High-temperature gas reactors use helium as a coolant due to its inertness and high thermal conductivity, while molten salt reactors rely on liquid salts as coolant, offering higher heat capacity but lower compatibility with helium-based systems.

Salt-based coolant loops

Molten salt reactors utilize salt-based coolant loops offering superior heat transfer and chemical stability compared to the helium-based coolant loops in high-temperature gas reactors.

Online fuel reprocessing

Molten salt reactors enable continuous online fuel reprocessing due to their liquid fuel medium, enhancing fuel efficiency and waste management, unlike high-temperature gas reactors which rely on solid fuel and batch-wise offline processing.

Pebble-bed core

The pebble-bed core in high-temperature gas reactors offers enhanced thermal efficiency and passive safety compared to the liquid-fueled, chemically complex molten salt reactors.

Fluoride salt mixtures

Fluoride salt mixtures in molten salt reactors provide superior heat transfer and chemical stability compared to the helium coolant used in high-temperature gas reactors, enhancing efficiency and corrosion resistance.

Compact heat exchanger

High-temperature gas reactors utilize compact heat exchangers with robust ceramic materials for efficient heat transfer at temperatures above 750degC, while molten salt reactors employ corrosion-resistant compact heat exchangers optimized for handling highly radioactive molten salts at similar high temperatures.

High outlet temperature

High-temperature gas reactors achieve outlet temperatures up to 950degC, enabling efficient hydrogen production and industrial process heat, while molten salt reactors typically operate at lower outlet temperatures around 700degC but offer enhanced thermal storage and safety features.

Passive decay heat removal

High-temperature gas reactors utilize ceramic-coated fuel and helium coolant for efficient passive decay heat removal, while molten salt reactors leverage their liquid fuel and high thermal conductivity salts to enable inherent passive heat dissipation.

high-temperature gas reactor vs molten salt reactor Infographic

njnir.com

njnir.com