Sodium-cooled reactors offer superior thermal conductivity and efficient heat transfer, allowing for high power density and excellent reactor performance. Lead-cooled reactors provide enhanced radiation shielding and corrosion resistance, improving safety and reducing maintenance demands. Both cooling technologies present distinct advantages in thermal efficiency, safety, and material compatibility for advanced nuclear systems.

Table of Comparison

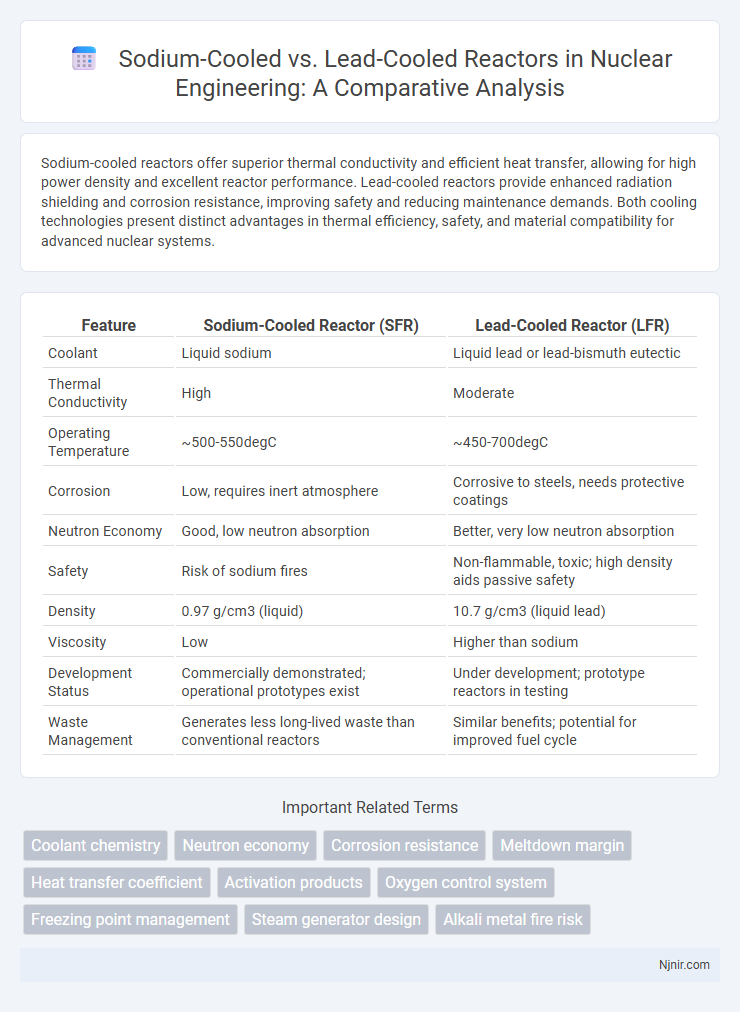

| Feature | Sodium-Cooled Reactor (SFR) | Lead-Cooled Reactor (LFR) |

|---|---|---|

| Coolant | Liquid sodium | Liquid lead or lead-bismuth eutectic |

| Thermal Conductivity | High | Moderate |

| Operating Temperature | ~500-550degC | ~450-700degC |

| Corrosion | Low, requires inert atmosphere | Corrosive to steels, needs protective coatings |

| Neutron Economy | Good, low neutron absorption | Better, very low neutron absorption |

| Safety | Risk of sodium fires | Non-flammable, toxic; high density aids passive safety |

| Density | 0.97 g/cm3 (liquid) | 10.7 g/cm3 (liquid lead) |

| Viscosity | Low | Higher than sodium |

| Development Status | Commercially demonstrated; operational prototypes exist | Under development; prototype reactors in testing |

| Waste Management | Generates less long-lived waste than conventional reactors | Similar benefits; potential for improved fuel cycle |

Introduction to Sodium-Cooled and Lead-Cooled Reactors

Sodium-cooled reactors use liquid sodium as a coolant to efficiently transfer heat from the reactor core, offering high thermal conductivity and low neutron absorption, which enhances neutron economy. Lead-cooled reactors employ molten lead or lead-bismuth eutectic as coolant, providing superior radiation shielding and chemical stability under high temperatures. Both reactor types support advanced fast neutron spectra for improved fuel utilization and reduced nuclear waste generation.

Historical Development of Coolant Technologies

Sodium-cooled reactors emerged prominently in the 1950s with the Experimental Breeder Reactor-I (EBR-I), showcasing high thermal conductivity and fast neutron spectrum advantages. Lead-cooled technology began gaining traction later, particularly in the 1970s, emphasizing corrosion resistance and inherent safety benefits in Generation IV reactor designs. Advances in material science and operational experience with sodium and lead coolants have continuously shaped their respective roles in fast reactor technology development.

Physical and Chemical Properties: Sodium vs. Lead

Sodium, a highly reactive alkali metal with low density and melting point (97.8degC), offers excellent thermal conductivity and low neutron absorption, making it ideal for fast reactor cooling. Lead, a dense post-transition metal with high melting point (327.5degC) and low vapor pressure, provides superior radiation shielding and chemical inertness but poses challenges due to its high density and corrosiveness at elevated temperatures. The contrasting physical and chemical properties of sodium and lead significantly influence coolant selection in advanced nuclear reactor designs.

Thermal Efficiency and Heat Transfer Capabilities

Sodium-cooled reactors exhibit superior thermal efficiency due to sodium's high thermal conductivity and low viscosity, enabling rapid heat transfer and efficient steam generation. Lead-cooled reactors benefit from lead's higher boiling point and excellent neutron shielding but have comparatively lower thermal conductivity, which can limit heat transfer rates and reduce overall thermal efficiency. The choice between sodium and lead coolants hinges on balancing sodium's superior heat transfer capabilities against lead's enhanced safety margins and corrosion resistance.

Safety Features and Risk Profiles

Sodium-cooled reactors utilize liquid sodium, which has excellent heat transfer properties but poses risks due to its high reactivity with water and air, increasing fire hazards and complicating leak management. Lead-cooled reactors benefit from lead's chemical inertness and high boiling point, reducing the risk of fire and allowing operation at low pressure, which enhances containment integrity and simplifies safety systems. While sodium-cooled systems require rigorous sealing and inert atmospheres to prevent sodium-water interactions, lead-cooled designs face challenges with material corrosion and heavier coolant handling but generally offer improved passive safety and lower risk of chemical accidents.

Corrosion and Material Compatibility

Sodium-cooled reactors exhibit lower corrosion rates due to sodium's chemical inertness with structural materials, but they require careful control of oxygen and impurities to prevent sodium oxide formation. Lead-cooled reactors face significant corrosion challenges as molten lead can aggressively attack steel, necessitating advanced high-chromium alloys and protective coatings to enhance material compatibility. Both systems demand rigorous material selection and monitoring to mitigate corrosion and ensure long-term reactor integrity.

Neutronic Performance and Fuel Cycle Impacts

Sodium-cooled fast reactors exhibit excellent neutron economy due to low neutron absorption and high thermal conductivity, enabling efficient fuel burnup and extended fuel cycles. Lead-cooled reactors provide superior neutron reflection and reduced parasitic neutron capture, enhancing breeding ratios and enabling more flexible fuel compositions, such as minor actinide recycling. Both coolants impact fuel cycle strategies by influencing neutron spectra and material compatibility, with sodium favoring conventional MOX fuels while lead supports advanced fuel cycles targeting waste minimization and closed fuel cycles.

Operational Experience and Global Deployment

Sodium-cooled reactors boast a rich operational history with over 400 reactor-years of experience, exemplified by successful projects such as Russia's BN series and the French Phenix and Superphenix reactors. Lead-cooled reactors remain largely in experimental stages with limited operational data, primarily from pilot projects like Russia's BREST-OD-300. Globally, sodium-cooled fast reactors have seen wider commercial deployment due to their mature technology and established supply chains, while lead-cooled designs are gaining attention for advanced nuclear programs focused on enhanced safety and breeding capabilities.

Waste Management and Environmental Considerations

Sodium-cooled reactors produce waste with activated sodium, posing chemical reactivity and disposal challenges requiring specialized containment to prevent environmental contamination. Lead-cooled reactors generate less chemically reactive waste, simplifying handling and reducing long-term environmental risks due to lead's stability and lower radiotoxicity in spent fuel byproducts. Waste management strategies favor lead-cooled systems for reduced corrosion and easier encapsulation, enhancing environmental safety and minimizing ecological impact.

Future Prospects and Research Directions

Sodium-cooled reactors exhibit established operational experience with fast neutron spectrum benefits, yet face challenges in chemical reactivity and coolant leakage risks, driving research toward advanced corrosion-resistant materials and enhanced safety systems. Lead-cooled reactors offer promising advantages such as high boiling points and low neutron moderation, spurring investigations into innovative lead-alloy compositions, structural materials resistant to lead corrosion, and integrated passive safety features. Both reactor types are integral to Generation IV nuclear systems, emphasizing development in fuel cycle optimization, waste minimization, and flexible deployment for sustainable and economically viable nuclear energy futures.

Coolant chemistry

Sodium-cooled reactors use liquid sodium with high thermal conductivity and chemical reactivity requiring inert atmosphere handling, while lead-cooled reactors utilize lead or lead-bismuth eutectic with lower chemical reactivity but increased corrosion challenges and higher melting points.

Neutron economy

Sodium-cooled reactors offer superior neutron economy due to lower neutron absorption compared to lead-cooled reactors, enhancing fuel efficiency and core performance.

Corrosion resistance

Lead-cooled reactors exhibit superior corrosion resistance compared to sodium-cooled reactors due to lead's lower chemical reactivity and reduced oxidation tendencies.

Meltdown margin

Sodium-cooled reactors offer a higher meltdown margin due to superior heat transfer properties and lower operating temperatures compared to lead-cooled reactors.

Heat transfer coefficient

Sodium-cooled reactors exhibit a higher heat transfer coefficient than lead-cooled reactors, enhancing thermal efficiency due to sodium's superior thermal conductivity and lower viscosity.

Activation products

Sodium-cooled reactors produce primarily sodium-24 activation products with short half-lives, while lead-cooled reactors generate fewer and less radiotoxic activation products such as polonium isotopes, impacting long-term radiological hazard management.

Oxygen control system

Sodium-cooled reactors require stringent oxygen control systems to prevent sodium oxidation and corrosion, while lead-cooled reactors benefit from a lower oxygen reactivity, reducing the complexity of oxygen control.

Freezing point management

Sodium-cooled reactors maintain efficient heat transfer with a low freezing point of 98degC, while lead-cooled reactors require advanced freezing point management due to lead's higher melting point of 327.5degC, affecting thermal stability and startup procedures.

Steam generator design

Steam generators in sodium-cooled reactors utilize compact, shell-and-tube heat exchangers to prevent sodium-water reactions, while lead-cooled reactor steam generators employ robust, corrosion-resistant designs to handle lead's high density and corrosiveness.

Alkali metal fire risk

Sodium-cooled reactors pose a higher alkali metal fire risk due to sodium's extreme reactivity with air and water, whereas lead-cooled reactors significantly reduce fire hazards because lead is non-flammable and chemically stable.

sodium-cooled vs lead-cooled Infographic

njnir.com

njnir.com