Sodium-cooled reactors offer superior thermal conductivity and excellent heat transfer capabilities, enabling high power density and efficient reactor operation. In contrast, lead-cooled reactors provide enhanced neutron economy and inherent safety features due to lead's high boiling point and low chemical reactivity. Both reactor types present unique advantages in terms of coolant properties, with sodium allowing for compact designs while lead offers improved corrosion resistance and reduced risk of fire.

Table of Comparison

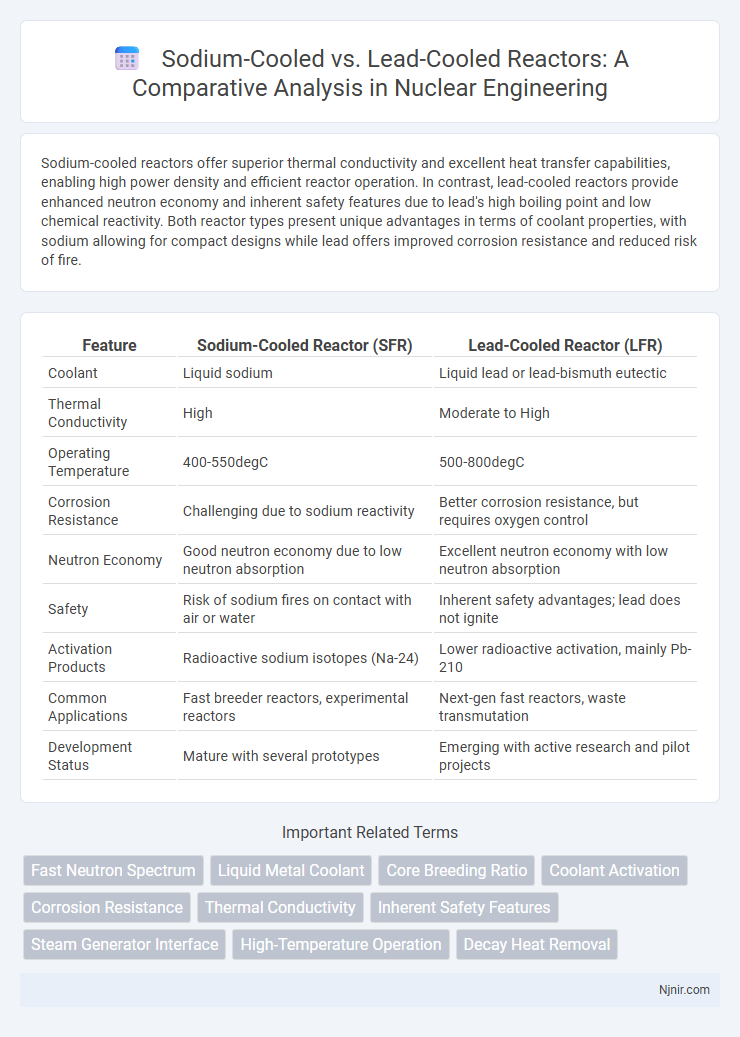

| Feature | Sodium-Cooled Reactor (SFR) | Lead-Cooled Reactor (LFR) |

|---|---|---|

| Coolant | Liquid sodium | Liquid lead or lead-bismuth eutectic |

| Thermal Conductivity | High | Moderate to High |

| Operating Temperature | 400-550degC | 500-800degC |

| Corrosion Resistance | Challenging due to sodium reactivity | Better corrosion resistance, but requires oxygen control |

| Neutron Economy | Good neutron economy due to low neutron absorption | Excellent neutron economy with low neutron absorption |

| Safety | Risk of sodium fires on contact with air or water | Inherent safety advantages; lead does not ignite |

| Activation Products | Radioactive sodium isotopes (Na-24) | Lower radioactive activation, mainly Pb-210 |

| Common Applications | Fast breeder reactors, experimental reactors | Next-gen fast reactors, waste transmutation |

| Development Status | Mature with several prototypes | Emerging with active research and pilot projects |

Introduction to Sodium-Cooled and Lead-Cooled Reactors

Sodium-cooled reactors utilize liquid sodium as a coolant, offering excellent thermal conductivity and efficient heat transfer at low pressures, which enhances reactor safety and operational efficiency. Lead-cooled reactors employ molten lead or lead-bismuth eutectic as coolant, providing high boiling points and strong radiation shielding, reducing the risk of coolant boiling and improving neutron economy. Both reactor types support fast neutron spectra, enabling efficient fuel utilization and potential for transuranic waste reduction in advanced nuclear fuel cycles.

Historical Development and Evolution

Sodium-cooled reactors (SFRs) trace their origins to the 1950s with the Experimental Breeder Reactor-I (EBR-I) in the United States, marking a pioneering step in fast neutron reactor technology. Lead-cooled reactors (LFRs), developed later in the 1970s primarily in Russia and Europe, evolved to address challenges related to coolant corrosion and radiological safety found in sodium systems. Both technologies have undergone continuous innovation, with modern designs emphasizing improved safety, higher operating temperatures, and extended fuel cycles to meet evolving energy demands.

Core Design and Coolant Properties

Sodium-cooled reactors utilize liquid sodium as a coolant due to its excellent thermal conductivity and low neutron absorption, enabling compact core designs with high power density and efficient heat transfer. Lead-cooled reactors, using liquid lead or lead-bismuth eutectic, benefit from a high boiling point and chemical inertness, allowing for simplified safety systems and reduced risk of coolant leaks, but typically require larger core volumes owing to lead's higher density and reduced neutron moderation. The choice between sodium and lead coolants significantly impacts core geometry, neutron economy, and thermal hydraulics, dictating reactor efficiency and safety margins.

Thermal Efficiency and Heat Transfer Performance

Sodium-cooled reactors exhibit high thermal conductivity and low neutron moderation, enabling efficient heat transfer and maintaining operational temperatures around 550-600degC, which supports thermal efficiencies typically between 40-45%. Lead-cooled reactors operate at higher temperatures, up to 700degC, benefiting from lead's high boiling point and inert chemical properties, resulting in improved thermal efficiency potentially exceeding 45%, while offering enhanced safety margins due to natural circulation capabilities. Comparative studies indicate that lead-cooled reactors provide superior heat transfer performance under transient conditions, whereas sodium-cooled systems require active pumping but achieve rapid heat removal due to sodium's excellent thermal conductivity.

Safety Features and Accident Tolerance

Sodium-cooled reactors utilize liquid sodium, which offers excellent heat transfer and a low neutron absorption cross-section, enhancing reactor efficiency but posing fire risks due to sodium's highly reactive nature with water and air. Lead-cooled reactors operate with lead or lead-bismuth eutectic coolants that are chemically inert and have a high boiling point, significantly reducing the risk of coolant fires and improving passive safety under accident conditions. Both reactor types incorporate inherent safety features, but lead-cooled reactors demonstrate superior accident tolerance by maintaining structural integrity and coolant availability at elevated temperatures without the risk of violent chemical reactions.

Material Compatibility and Corrosion Issues

Sodium-cooled reactors utilize liquid sodium as a coolant, which exhibits excellent heat transfer properties but poses challenges due to its high chemical reactivity and potential for corrosion with structural materials like stainless steel and fuel cladding. Lead-cooled reactors benefit from lead's low chemical reactivity and high boiling point, reducing corrosion risks; however, lead can cause liquid metal embrittlement and oxidation issues in certain alloys, requiring advanced corrosion-resistant materials such as lead-compatible steels or coatings. Material compatibility in sodium-cooled systems demands careful control of impurities to prevent corrosion, while lead-cooled reactors focus on mitigating solid lead oxide formation and managing corrosion through oxygen control and material innovation.

Fuel Cycle and Waste Management

Sodium-cooled reactors utilize a closed fuel cycle with fast neutron spectra enabling efficient recycling of plutonium and minor actinides, reducing long-term radiotoxicity and volume of high-level waste. Lead-cooled reactors offer superior resistance to corrosion and neutron activation in the coolant, facilitating simpler fuel recycling processes with less secondary waste. Both systems aim to minimize nuclear waste, but lead-cooled designs typically generate lower amounts of activated coolant byproducts, enhancing waste management strategies.

Proliferation Resistance and Security

Sodium-cooled reactors exhibit moderate proliferation resistance due to liquid sodium's opacity and reactivity, which complicates fuel handling and reprocessing, whereas lead-cooled reactors offer enhanced proliferation resistance because of their low neutron absorption and minimal production of weapons-grade plutonium. The chemical inertness and low volatility of lead reduce the risk of radioactive release, improving security in accident scenarios compared to sodium's high chemical reactivity and fire hazard. Overall, lead-cooled reactors present a safer and more proliferation-resistant option in the context of advanced nuclear reactor designs.

Economic Considerations and Scalability

Sodium-cooled reactors offer lower operating costs due to sodium's superior heat transfer properties and established supply chains, enabling efficient thermal output at commercial scales. Lead-cooled reactors benefit from reduced coolant corrosion and longer component lifespans, potentially lowering long-term maintenance expenses and increasing reactor availability. Scalability favors sodium-cooled designs with modular configurations already tested in pilot plants, while lead-cooled reactors are advancing in developmental stages, promising enhanced scalability through simplified safety systems and high thermal inertia.

Future Prospects and Research Directions

Sodium-cooled reactors (SFRs) benefit from extensive operational experience and ongoing advancements in improving safety measures and fuel cycle efficiency, positioning them as strong candidates for near-term deployment in fast reactor fleets. Lead-cooled reactors (LFRs) offer promising potential due to their inherent safety features, high boiling point, and chemical inertness of lead coolant, driving research towards corrosion-resistant materials and thermal-hydraulic optimization for long-term sustainability. Future research prioritizes enhancing fuel performance, extending component lifetimes, and integrating these reactors into advanced closed fuel cycle systems to achieve economic competitiveness and waste minimization.

Fast Neutron Spectrum

Sodium-cooled fast reactors use liquid sodium as a coolant to effectively sustain a fast neutron spectrum enhancing fuel breeding, while lead-cooled fast reactors employ lead coolant providing superior neutron economy and corrosion resistance for efficient fast neutron reactor operations.

Liquid Metal Coolant

Sodium-cooled reactors offer high thermal conductivity and low neutron absorption with reactive sodium coolant, while lead-cooled reactors provide superior radiation shielding and corrosion resistance using denser, less chemically reactive lead coolant.

Core Breeding Ratio

Lead-cooled reactors typically achieve higher core breeding ratios compared to sodium-cooled reactors due to lead's superior neutron economy and lower neutron absorption cross-section.

Coolant Activation

Sodium-cooled reactors exhibit higher coolant activation due to neutron absorption producing radioactive isotopes like Na-24, while lead-cooled reactors have lower coolant activation because lead generates fewer neutron-induced radionuclides.

Corrosion Resistance

Lead-cooled reactors exhibit superior corrosion resistance compared to sodium-cooled reactors due to lead's inert chemical properties and higher boiling point, reducing material degradation in high-temperature environments.

Thermal Conductivity

Sodium-cooled reactors exhibit thermal conductivity around 142 W/m*K at operating temperatures, enabling efficient heat transfer compared to lead-cooled reactors, which have lower thermal conductivity approximately 35 W/m*K, impacting their heat removal performance.

Inherent Safety Features

Sodium-cooled reactors offer inherent safety through excellent heat transfer and low operating pressure, while lead-cooled reactors provide superior passive safety due to their high boiling point and natural corrosion resistance.

Steam Generator Interface

Sodium-cooled reactors utilize an intermediate sodium loop to transfer heat to the steam generator, minimizing chemical reactions and corrosion risks, whereas lead-cooled reactors directly transfer heat to the steam generator with higher thermal inertia but face challenges from lead's corrosiveness and higher melting point.

High-Temperature Operation

Sodium-cooled reactors operate efficiently at temperatures around 550-600degC due to sodium's excellent thermal conductivity and low neutron absorption, while lead-cooled reactors enable higher temperature operations exceeding 700degC, offering improved thermal efficiency and inherent safety through lead's high boiling point and chemical inertness.

Decay Heat Removal

Sodium-cooled reactors offer superior decay heat removal efficiency due to sodium's high thermal conductivity and low boiling point compared to lead-cooled reactors, which rely on lead's higher boiling point but lower thermal conductivity, impacting passive safety performance.

sodium-cooled reactor vs lead-cooled reactor Infographic

njnir.com

njnir.com