High temperature gas-cooled reactors (HTGRs) operate at significantly higher temperatures than light water reactors (LWRs), enabling higher thermal efficiency and hydrogen production capabilities. HTGRs use helium as a coolant, which is inert and avoids corrosion issues seen in the water-based coolant of LWRs. The advanced fuel design in HTGRs provides enhanced safety margins and resistance to meltdown compared to traditional LWR fuel assemblies.

Table of Comparison

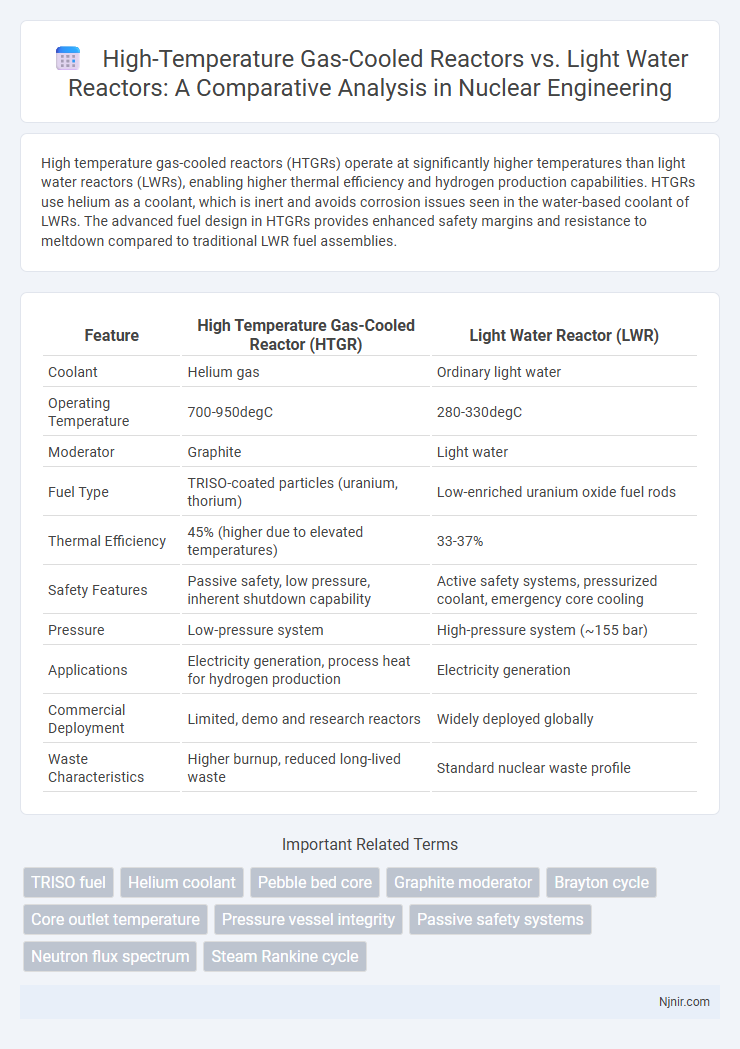

| Feature | High Temperature Gas-Cooled Reactor (HTGR) | Light Water Reactor (LWR) |

|---|---|---|

| Coolant | Helium gas | Ordinary light water |

| Operating Temperature | 700-950degC | 280-330degC |

| Moderator | Graphite | Light water |

| Fuel Type | TRISO-coated particles (uranium, thorium) | Low-enriched uranium oxide fuel rods |

| Thermal Efficiency | 45% (higher due to elevated temperatures) | 33-37% |

| Safety Features | Passive safety, low pressure, inherent shutdown capability | Active safety systems, pressurized coolant, emergency core cooling |

| Pressure | Low-pressure system | High-pressure system (~155 bar) |

| Applications | Electricity generation, process heat for hydrogen production | Electricity generation |

| Commercial Deployment | Limited, demo and research reactors | Widely deployed globally |

| Waste Characteristics | Higher burnup, reduced long-lived waste | Standard nuclear waste profile |

Introduction to High Temperature Gas-Cooled Reactors and Light Water Reactors

High Temperature Gas-Cooled Reactors (HTGRs) utilize helium gas as a coolant and graphite as a moderator, operating at temperatures exceeding 700degC, which enhances thermal efficiency and offers superior safety characteristics compared to traditional designs. Light Water Reactors (LWRs), including Pressurized Water Reactors (PWRs) and Boiling Water Reactors (BWRs), use ordinary water as both coolant and neutron moderator, operating at temperatures around 300degC with well-established technology dominating global nuclear power generation. HTGRs provide advantages in high-temperature process heat applications and inherent safety features, while LWRs benefit from widespread operational experience and extensive infrastructure support.

Core Design and Fuel Characteristics

High temperature gas-cooled reactors (HTGRs) feature a graphite-moderated core with TRISO fuel particles embedded in carbon-based fuel compacts, enabling operation at outlet temperatures exceeding 750degC for superior thermal efficiency. Light water reactors (LWRs) utilize zirconium alloy-clad uranium oxide fuel rods arranged in assemblies moderated and cooled by ordinary water, with core temperatures typically around 300degC. The ceramic TRISO fuel in HTGRs provides enhanced fission product retention and higher burnup rates compared to the conventional oxide fuel in LWRs, resulting in improved safety margins and fuel utilization.

Coolant Selection and Heat Transfer Efficiency

High temperature gas-cooled reactors (HTGRs) use helium as a coolant, which offers superior thermal conductivity and allows operation at temperatures exceeding 750degC, enhancing heat transfer efficiency and enabling high thermal output for industrial processes. In contrast, light water reactors (LWRs) utilize ordinary water as both coolant and moderator, operating at lower temperatures around 300degC, which limits thermal efficiency but provides effective neutron moderation and reliable heat removal. The inert nature of helium in HTGRs reduces corrosion and increases safety margins, whereas the high heat capacity of water in LWRs ensures efficient heat transfer despite lower operating temperatures.

Reactor Safety Features and Risk Analysis

High temperature gas-cooled reactors (HTGRs) utilize helium coolant and TRISO fuel particles, providing inherent safety features such as high thermal conductivity and low power density that minimize the risk of core meltdown under accident conditions. Light water reactors (LWRs), relying on water as both coolant and moderator, depend heavily on active safety systems, including emergency core cooling and containment structures, to prevent overheating and radiation release. Risk analysis indicates HTGRs have lower likelihood of severe accidents due to passive safety characteristics and robust fuel design, whereas LWRs require complex operational safeguards to mitigate higher vulnerability during loss-of-coolant incidents.

Thermal Efficiency and Power Output Comparison

High temperature gas-cooled reactors (HTGRs) achieve thermal efficiencies up to 45%, significantly higher than light water reactors (LWRs), which typically reach around 33%. HTGRs operate at coolant outlet temperatures exceeding 750degC, enabling more efficient electricity generation and potential industrial process heat applications. In terms of power output, LWRs commonly produce between 1,000 to 1,600 MW(e), whereas HTGR designs often target modular outputs around 200 to 600 MW(e), emphasizing scalability and high-efficiency performance.

Fuel Utilization and Waste Management

High temperature gas-cooled reactors (HTGRs) achieve higher fuel utilization by operating at elevated temperatures, allowing for better thermal efficiency and more complete fission of uranium fuel compared to light water reactors (LWRs), which utilize lower temperature steam cycles. HTGRs use TRISO fuel particles encapsulated in graphite, enhancing safety and enabling prolonged fuel burnup while reducing the volume and toxicity of spent fuel. In contrast, LWRs produce larger quantities of high-level radioactive waste due to lower burnup rates and require extensive reprocessing or long-term storage solutions.

Operational Flexibility and Load-Following Capabilities

High Temperature Gas-Cooled Reactors (HTGRs) exhibit superior operational flexibility and load-following capabilities compared to Light Water Reactors (LWRs) due to their robust fuel design and high thermal inertia, enabling efficient ramp-up and ramp-down of power output without compromising safety. HTGRs can adjust power levels dynamically in response to grid demands, leveraging their high outlet temperatures and inert helium coolant which facilitate rapid thermal transients. In contrast, LWRs operate optimally at steady-state conditions with limited load-following capacity due to thermal stress constraints on fuel cladding and primary loop components, restricting frequent power adjustments.

Economic Considerations and Construction Costs

High temperature gas-cooled reactors (HTGRs) typically incur higher upfront construction costs than light water reactors (LWRs) due to advanced materials and specialized components needed to withstand extreme temperatures, impacting initial capital investment. LWRs benefit from established supply chains, standardized designs, and economies of scale, resulting in lower construction expenses and shorter project timelines, enhancing their economic attractiveness. Over the reactor lifecycle, HTGRs potentially offer cost savings through higher thermal efficiency and reduced fuel consumption, which can offset initial expenditures but require detailed economic modeling to validate long-term financial benefits.

Environmental Impact and Regulatory Compliance

High Temperature Gas-Cooled Reactors (HTGRs) generate less radioactive waste and enable higher thermal efficiency compared to Light Water Reactors (LWRs), reducing environmental impact by producing lower emissions and minimizing long-term storage challenges. HTGRs utilize helium as a coolant, which is chemically inert, mitigating risks of chemical pollution and enhancing safety, while LWRs rely on water, presenting challenges such as thermal pollution and potential hydrogen production during accidents. Regulatory compliance for HTGRs is evolving with a focus on passive safety features and modular designs, whereas LWRs face stringent, well-established regulations addressing coolant chemistry, emergency core cooling, and containment systems.

Future Prospects and Technological Advancements

High temperature gas-cooled reactors (HTGRs) offer enhanced thermal efficiency and improved safety features compared to traditional light water reactors (LWRs), making them promising candidates for next-generation nuclear power. Technological advancements in HTGR fuel design and materials science enable operation at higher temperatures, facilitating hydrogen production and industrial process heat applications beyond electricity generation. Future prospects for HTGRs include integration with renewable energy systems and deployment in modular formats, potentially accelerating the transition to low-carbon and flexible energy infrastructures.

TRISO fuel

High Temperature Gas-Cooled Reactors (HTGRs) utilize TRISO fuel particles with superior fission product retention and high-temperature stability, offering enhanced safety and efficiency compared to Light Water Reactors (LWRs) that use conventional uranium oxide fuel.

Helium coolant

High temperature gas-cooled reactors use helium coolant for superior thermal conductivity and chemical inertness, enabling higher operating temperatures and improved efficiency compared to water-cooled light water reactors.

Pebble bed core

The high-temperature gas-cooled reactor features a pebble bed core composed of spherical fuel elements allowing improved heat transfer and inherent safety compared to the light water reactor's solid fuel assemblies.

Graphite moderator

High temperature gas-cooled reactors use graphite moderators to achieve higher thermal efficiency and improved neutron economy compared to light water reactors that use water moderators.

Brayton cycle

High temperature gas-cooled reactors (HTGRs) enhance thermal efficiency by utilizing the Brayton cycle, which operates at higher temperatures compared to the Rankine cycle used in light water reactors (LWRs), enabling more efficient electricity generation and improved fuel utilization.

Core outlet temperature

High temperature gas-cooled reactors achieve core outlet temperatures up to 750-950degC, significantly higher than light water reactors' typical 290-330degC, enabling improved thermal efficiency and hydrogen production.

Pressure vessel integrity

High Temperature Gas-Cooled Reactors maintain superior pressure vessel integrity compared to Light Water Reactors due to lower operating pressures and enhanced material resilience against corrosion and thermal stresses.

Passive safety systems

High temperature gas-cooled reactors feature passive safety systems relying on natural convection and radiation cooling to maintain safe temperatures without active controls, whereas light water reactors primarily depend on active cooling systems and engineered safety features.

Neutron flux spectrum

High temperature gas-cooled reactors exhibit a harder neutron flux spectrum compared to light water reactors, resulting in higher neutron energies that enhance fuel utilization and enable efficient waste transmutation.

Steam Rankine cycle

High Temperature Gas-Cooled Reactors (HTGRs) achieve higher thermal efficiencies in Steam Rankine cycle applications compared to Light Water Reactors (LWRs) due to their elevated outlet temperatures exceeding 700degC versus LWRs' typical 300degC, enhancing steam quality and turbine performance.

high temperature gas-cooled reactor vs light water reactor Infographic

njnir.com

njnir.com