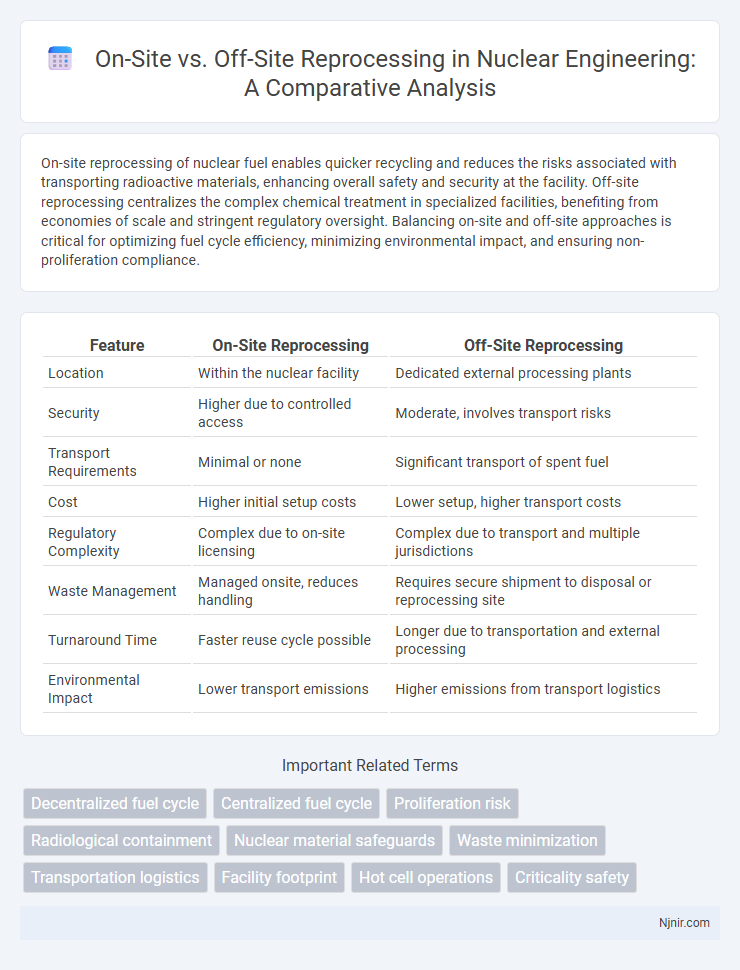

On-site reprocessing of nuclear fuel enables quicker recycling and reduces the risks associated with transporting radioactive materials, enhancing overall safety and security at the facility. Off-site reprocessing centralizes the complex chemical treatment in specialized facilities, benefiting from economies of scale and stringent regulatory oversight. Balancing on-site and off-site approaches is critical for optimizing fuel cycle efficiency, minimizing environmental impact, and ensuring non-proliferation compliance.

Table of Comparison

| Feature | On-Site Reprocessing | Off-Site Reprocessing |

|---|---|---|

| Location | Within the nuclear facility | Dedicated external processing plants |

| Security | Higher due to controlled access | Moderate, involves transport risks |

| Transport Requirements | Minimal or none | Significant transport of spent fuel |

| Cost | Higher initial setup costs | Lower setup, higher transport costs |

| Regulatory Complexity | Complex due to on-site licensing | Complex due to transport and multiple jurisdictions |

| Waste Management | Managed onsite, reduces handling | Requires secure shipment to disposal or reprocessing site |

| Turnaround Time | Faster reuse cycle possible | Longer due to transportation and external processing |

| Environmental Impact | Lower transport emissions | Higher emissions from transport logistics |

Introduction to Nuclear Fuel Reprocessing

Nuclear fuel reprocessing involves recovering usable fissile materials from spent nuclear fuel to reduce waste and extend fuel supply. On-site reprocessing occurs within the nuclear power plant facility, enabling immediate recycling and minimizing transportation risks, while off-site reprocessing takes place at specialized external plants designed for large-scale treatment and advanced chemical separation techniques. Understanding the balance between operational efficiency, safety measures, regulatory compliance, and economic factors is essential in selecting the appropriate reprocessing method for nuclear fuel cycle management.

Overview of On-Site Reprocessing

On-site reprocessing involves sterilizing and preparing medical instruments within the healthcare facility, ensuring immediate availability and reducing turnaround time. This method enables tighter control over instrument integrity and adherence to infection control protocols compared to off-site options. It often requires significant investment in infrastructure and trained personnel to maintain compliance with regulatory standards.

Overview of Off-Site Reprocessing

Off-site reprocessing involves transporting used medical instruments to a specialized external facility where thorough cleaning, sterilization, and quality control are conducted under stringent regulatory standards. This method reduces the burden on healthcare facilities by outsourcing complex sterilization processes, often ensuring higher compliance with safety protocols and advanced technology utilization. Off-site reprocessing can enhance instrument turnaround time reliability and cost-effectiveness when compared to on-site reprocessing.

Technological Considerations in Reprocessing Methods

On-site reprocessing allows for real-time monitoring and immediate troubleshooting of sterilization equipment, ensuring consistent adherence to infection control standards through advanced automated systems. Off-site reprocessing relies on specialized high-capacity sterilization technology and centralized quality control, offering scalability but requiring stringent logistical controls to maintain device integrity during transport. Both methods demand validation of sterilization cycles, compatibility with medical device materials, and integration of advanced tracking systems to optimize safety and efficiency in healthcare facilities.

Safety and Security Implications

On-site reprocessing of medical instruments enables immediate sterilization, reducing the risk of contamination and enhancing patient safety by maintaining strict control over the process. Off-site reprocessing, while often cost-effective, introduces increased security concerns regarding the transport and potential loss or damage of sterile equipment, along with delayed turnaround times that may compromise clinical workflow. Implementing robust tracking systems and adherence to regulatory standards are critical to mitigating safety and security risks in both reprocessing models.

Economic Analysis: On-Site vs Off-Site

On-site reprocessing of medical instruments significantly reduces transportation and turnaround time costs compared to off-site reprocessing, which involves higher logistical expenses and potential delays. Economic analysis reveals that on-site reprocessing lowers labor costs by optimizing staff utilization and minimizing instrument downtime, enhancing operational efficiency. Despite higher initial setup costs, on-site reprocessing offers greater long-term cost savings and improved asset management versus off-site alternatives.

Environmental Impact and Waste Management

On-site reprocessing significantly reduces environmental impact by minimizing transportation emissions and enabling immediate waste segregation and recycling, which decreases landfill contributions and resource consumption. Off-site reprocessing often involves higher carbon footprints due to logistics and the risk of increased packaging waste, though it centralizes waste management for specialized disposal. Both methods influence waste stream efficiency, but on-site reprocessing offers superior control over hazardous material handling and promotes sustainable waste reduction practices within healthcare facilities.

Regulatory and Policy Frameworks

On-site reprocessing of medical devices is governed by stringent regulatory frameworks such as the FDA's Quality System Regulation (QSR) in the United States, ensuring compliance with sterilization and validation standards. Off-site reprocessing facilities must adhere to both the originating healthcare facility's policies and external accreditation requirements, including guidance from bodies like the Association for the Advancement of Medical Instrumentation (AAMI) and state health departments. Differences in regulatory oversight often influence decision-making, with on-site reprocessing allowing direct control over compliance but off-site reprocessing demanding rigorous contractual and procedural monitoring to meet quality and safety standards.

Case Studies and Real-World Applications

Case studies highlight that on-site reprocessing of medical devices ensures faster turnaround times and maintains sterility standards, reducing hospital inventory costs and improving patient safety. Real-world applications demonstrate off-site reprocessing's advantage in scalability and specialized cleaning capabilities, often lowering operational expenses for healthcare facilities. Comparative analyses reveal hospitals with in-house reprocessing achieve enhanced control and compliance, while outsourced models benefit from advanced technology and regulatory expertise.

Future Trends and Innovations in Reprocessing

Future trends in reprocessing emphasize automation and artificial intelligence integration to enhance efficiency and reduce human error in both on-site and off-site settings. Innovations in advanced sterilization technologies, including low-temperature plasma and vaporized hydrogen peroxide, are improving microbial eradication while preserving instrument longevity. The rise of blockchain for traceability and IoT-enabled smart tracking systems ensures real-time monitoring and compliance, driving improvements in safety and operational transparency.

Decentralized fuel cycle

Decentralized fuel cycle systems benefit from on-site reprocessing by reducing transportation risks and enhancing material security compared to off-site reprocessing facilities.

Centralized fuel cycle

Centralized fuel cycle management enhances efficiency and safety by consolidating off-site reprocessing facilities, reducing transportation risks and enabling advanced technology deployment compared to on-site reprocessing.

Proliferation risk

On-site reprocessing significantly reduces proliferation risk by maintaining strict control over nuclear materials, whereas off-site reprocessing increases proliferation vulnerabilities due to transportation and external facility security challenges.

Radiological containment

On-site reprocessing ensures tighter radiological containment through immediate handling and reduced transportation risks compared to off-site reprocessing.

Nuclear material safeguards

On-site reprocessing ensures real-time nuclear material accountability and enhances safeguards by minimizing material transfer risks, whereas off-site reprocessing requires stringent transportation security and delayed material verification.

Waste minimization

On-site reprocessing significantly minimizes medical waste by allowing immediate sterilization and reuse of instruments, whereas off-site reprocessing often generates higher waste due to increased packaging and transportation requirements.

Transportation logistics

On-site reprocessing eliminates complex transportation logistics by enabling immediate instrument sterilization, reducing turnaround time and minimizing risk of contamination or loss during off-site transit.

Facility footprint

On-site reprocessing minimizes facility footprint by eliminating the need for centralized sterilization areas mandated by off-site reprocessing, optimizing space utilization within healthcare facilities.

Hot cell operations

Hot cell operations in on-site reprocessing provide enhanced nuclear material handling safety and real-time process control compared to off-site reprocessing facilities.

Criticality safety

On-site reprocessing enhances criticality safety by enabling immediate monitoring and control of nuclear materials, reducing the risk of accidental chain reactions compared to off-site reprocessing.

on-site reprocessing vs off-site reprocessing Infographic

njnir.com

njnir.com