Zirconium cladding offers superior neutron economy due to its low neutron absorption cross-section compared to stainless steel cladding, enhancing reactor fuel efficiency. Its excellent corrosion resistance and mechanical strength under high-temperature reactor conditions reduce the risk of cladding failure, improving safety margins. Stainless steel cladding, while more robust against mechanical stresses, suffers from higher neutron absorption and corrosion susceptibility, making zirconium alloys the preferred choice in most light water reactors.

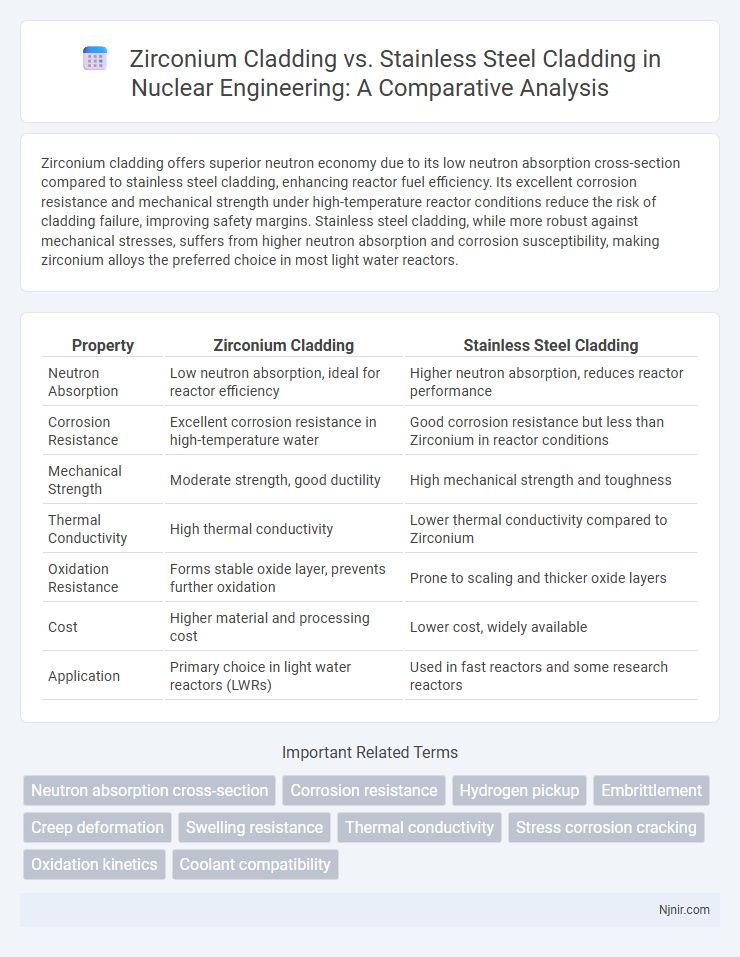

Table of Comparison

| Property | Zirconium Cladding | Stainless Steel Cladding |

|---|---|---|

| Neutron Absorption | Low neutron absorption, ideal for reactor efficiency | Higher neutron absorption, reduces reactor performance |

| Corrosion Resistance | Excellent corrosion resistance in high-temperature water | Good corrosion resistance but less than Zirconium in reactor conditions |

| Mechanical Strength | Moderate strength, good ductility | High mechanical strength and toughness |

| Thermal Conductivity | High thermal conductivity | Lower thermal conductivity compared to Zirconium |

| Oxidation Resistance | Forms stable oxide layer, prevents further oxidation | Prone to scaling and thicker oxide layers |

| Cost | Higher material and processing cost | Lower cost, widely available |

| Application | Primary choice in light water reactors (LWRs) | Used in fast reactors and some research reactors |

Introduction to Fuel Cladding in Nuclear Reactors

Fuel cladding in nuclear reactors serves as a critical barrier, preventing the release of radioactive fission products while maintaining structural integrity under high temperature and radiation. Zirconium (Zr) cladding offers superior neutron transparency and corrosion resistance compared to stainless steel cladding, making it the preferred material in most commercial light water reactors. Stainless steel cladding, although mechanically robust and cost-effective, exhibits higher neutron absorption and lower corrosion resistance, limiting its use primarily to specific reactor designs or fuel assemblies.

Material Properties of Zirconium Alloys

Zirconium alloys used in cladding exhibit exceptional corrosion resistance and low neutron absorption cross-section, making them ideal for nuclear reactor environments. Their high strength-to-weight ratio and superior thermal conductivity enhance fuel efficiency and safety during operation. Compared to stainless steel cladding, zirconium alloys provide better irradiation resistance and reduced hydrogen uptake, minimizing the risk of embrittlement and cladding failure.

Material Properties of Stainless Steel

Stainless steel cladding offers excellent corrosion resistance, high tensile strength, and superior toughness at elevated temperatures, making it suitable for harsh environments. Its alloy composition, typically including chromium, nickel, and molybdenum, enhances oxidation resistance and inhibits stress corrosion cracking. Stainless steel exhibits good weldability and thermal conductivity, which supports structural integrity and heat dissipation in various industrial applications.

Corrosion Resistance in Reactor Environments

Zirconium cladding demonstrates superior corrosion resistance in reactor environments due to its low neutron absorption cross-section and the formation of a stable, protective oxide layer under high-temperature water conditions. Stainless steel cladding, while mechanically robust, is more prone to corrosion and stress corrosion cracking in high-temperature, high-pressure reactor coolant systems, especially in pressurized water reactors (PWRs). The enhanced corrosion resistance of zirconium alloys extends fuel life and improves overall reactor safety by minimizing cladding degradation during operation.

Neutron Economy: Zirconium vs Stainless Steel

Zirconium cladding exhibits superior neutron economy compared to stainless steel due to its low neutron absorption cross-section, minimizing neutron loss in the reactor core. Stainless steel cladding, with a higher neutron absorption cross-section, reduces the number of neutrons available for sustaining the fission chain reaction, affecting reactor efficiency. Consequently, zirconium alloys are preferred in nuclear reactors to optimize neutron economy and fuel utilization.

Mechanical Performance Under Irradiation

Zirconium (Zr) cladding exhibits superior mechanical performance under irradiation due to its low neutron absorption cross-section and excellent corrosion resistance, maintaining structural integrity in nuclear reactor environments. Stainless steel cladding, while offering higher initial strength and toughness, tends to suffer from radiation-induced swelling and embrittlement, reducing its mechanical reliability over prolonged exposure. Zr cladding's enhanced dimensional stability and resistance to irradiation-induced degradation make it the preferred choice for fuel rod cladding in light water reactors.

Thermal Conductivity Comparison

Zirconium cladding exhibits significantly higher thermal conductivity, typically around 16-18 W/m*K, compared to stainless steel cladding, which ranges from 14-16 W/m*K depending on the alloy composition. This superior thermal conductivity of Zr cladding enhances heat transfer efficiency in nuclear fuel rods, reducing fuel temperature and improving reactor safety margins. Consequently, Zr cladding is preferred in most nuclear reactors due to its better thermal performance under high-temperature operating conditions.

Safety Implications: Accident Tolerance

Zirconium cladding exhibits superior accident tolerance compared to stainless steel cladding due to its lower oxidation rate and reduced hydrogen generation under high-temperature conditions, which significantly enhances reactor safety during loss-of-coolant accidents. The reduced propensity of zirconium alloys to produce flammable hydrogen gas minimizes explosion risks, ensuring safer containment integrity in severe scenarios. Stainless steel cladding, while corrosion-resistant, can accelerate oxidation and embrittlement under extreme heat, compromising accident tolerance and overall reactor safety.

Cost and Fabrication Considerations

Zr cladding offers superior corrosion resistance and neutron economy, making it more expensive due to complex fabrication processes such as extrusion and pilgering, which require specialized equipment and stringent quality control. Stainless steel cladding is generally lower in cost with simpler manufacturing techniques like hot rolling and welding, but it has higher neutron absorption and corrosion concerns in certain reactor environments. The choice between Zr and stainless steel cladding hinges on cost-efficiency balanced against fabrication complexity and long-term reactor performance.

Future Trends in Nuclear Cladding Materials

Future trends in nuclear cladding materials emphasize the development of advanced zirconium alloys and enhanced stainless steel variants to improve resistance to oxidation, corrosion, and radiation damage. Research focuses on incorporating nanostructured coatings and ceramic barriers to extend fuel lifespan and safety margins under higher burnup conditions. Innovations in accident-tolerant fuel cladding aim to combine the mechanical strength of stainless steel with the neutron transparency and lower hydrogen uptake of zirconium-based materials.

Neutron absorption cross-section

Zirconium cladding exhibits a significantly lower neutron absorption cross-section than stainless steel cladding, enhancing fuel efficiency and reactor performance in nuclear reactors.

Corrosion resistance

Zirconium cladding offers superior corrosion resistance in high-temperature reactor environments compared to stainless steel cladding, making it the preferred material for nuclear fuel rods.

Hydrogen pickup

Zirconium cladding exhibits significantly lower hydrogen pickup rates compared to stainless steel cladding, reducing the risk of embrittlement and enhancing fuel rod integrity in nuclear reactors.

Embrittlement

Zirconium cladding exhibits superior resistance to embrittlement compared to stainless steel cladding due to its lower susceptibility to hydrogen pickup and irradiation-induced damage in nuclear reactors.

Creep deformation

Zirconium cladding exhibits significantly lower creep deformation rates than stainless steel cladding under high-temperature reactor conditions, enhancing fuel rod integrity and lifespan.

Swelling resistance

Zirconium cladding exhibits superior swelling resistance compared to stainless steel cladding, making it more effective in maintaining structural integrity under high neutron irradiation in nuclear reactors.

Thermal conductivity

Zirconium cladding exhibits significantly higher thermal conductivity than stainless steel cladding, enhancing heat transfer efficiency in nuclear reactor fuel rods.

Stress corrosion cracking

Zirconium cladding exhibits significantly higher resistance to stress corrosion cracking compared to stainless steel cladding, making it the preferred material in nuclear reactor fuel rods exposed to high-temperature water environments.

Oxidation kinetics

Zirconium cladding exhibits significantly slower oxidation kinetics than stainless steel cladding, enhancing corrosion resistance and prolonging reactor fuel integrity under high-temperature conditions.

Coolant compatibility

Zirconium cladding offers superior coolant compatibility due to its low neutron absorption and excellent corrosion resistance in high-temperature water environments compared to stainless steel cladding.

Zr cladding vs stainless steel cladding Infographic

njnir.com

njnir.com