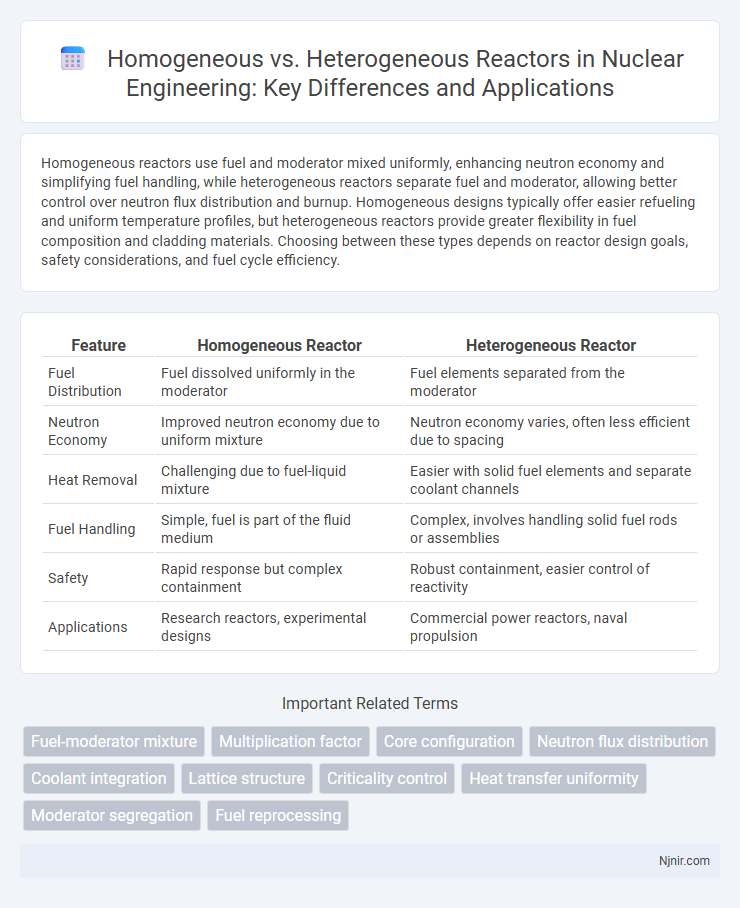

Homogeneous reactors use fuel and moderator mixed uniformly, enhancing neutron economy and simplifying fuel handling, while heterogeneous reactors separate fuel and moderator, allowing better control over neutron flux distribution and burnup. Homogeneous designs typically offer easier refueling and uniform temperature profiles, but heterogeneous reactors provide greater flexibility in fuel composition and cladding materials. Choosing between these types depends on reactor design goals, safety considerations, and fuel cycle efficiency.

Table of Comparison

| Feature | Homogeneous Reactor | Heterogeneous Reactor |

|---|---|---|

| Fuel Distribution | Fuel dissolved uniformly in the moderator | Fuel elements separated from the moderator |

| Neutron Economy | Improved neutron economy due to uniform mixture | Neutron economy varies, often less efficient due to spacing |

| Heat Removal | Challenging due to fuel-liquid mixture | Easier with solid fuel elements and separate coolant channels |

| Fuel Handling | Simple, fuel is part of the fluid medium | Complex, involves handling solid fuel rods or assemblies |

| Safety | Rapid response but complex containment | Robust containment, easier control of reactivity |

| Applications | Research reactors, experimental designs | Commercial power reactors, naval propulsion |

Introduction to Nuclear Reactors

Homogeneous reactors contain fuel and moderator mixed in a single phase, often a liquid solution, which allows for uniform neutron flux distribution and efficient heat transfer. Heterogeneous reactors separate fuel and moderator into distinct regions, commonly solid fuel rods surrounded by a moderator, optimizing neutron economy and structural integrity. Understanding these reactor types is fundamental in nuclear reactor design, influencing performance, safety, and fuel utilization.

Defining Homogeneous Reactors

Homogeneous reactors are nuclear reactors where the fuel and moderator are uniformly mixed in a single phase, usually a liquid solution containing fissile material, enabling consistent neutron moderation throughout the reactor core. This uniform mixture enhances neutron economy and allows for simpler heat removal due to the direct contact of fuel and coolant. Homogeneous reactors contrast with heterogeneous reactors, where fuel and moderator exist as separate, distinct materials arranged spatially within the core.

Understanding Heterogeneous Reactors

Heterogeneous reactors feature distinct phases where the catalyst is in a different state than the reactants, commonly solid catalysts interacting with gaseous or liquid reactants, promoting efficient surface reactions. These reactors allow better control over reaction rates and selectivity due to catalyst surface properties and improved separation of products from catalysts. Compared to homogeneous reactors, heterogeneous reactors typically offer enhanced durability, easier catalyst recovery, and reduced corrosion issues, making them preferable in industrial applications such as petrochemical refining and environmental catalysis.

Core Design and Fuel Configuration

Homogeneous reactors feature fuel mixed uniformly with the moderator, resulting in a single-phase core that ensures consistent neutron moderation and simplified heat transfer. Heterogeneous reactors separate the fuel from the moderator, typically arranging fuel rods or assemblies within a moderator matrix to optimize neutron economy and enable higher fuel enrichment levels. Core design in homogeneous reactors emphasizes fluid dynamics and chemical stability, while heterogeneous reactors focus on mechanical support structures and thermal-mechanical performance of discrete fuel elements.

Neutron Moderation and Control Mechanisms

Homogeneous reactors feature fuel and moderator mixed uniformly, allowing efficient neutron moderation through consistent neutron slowing and absorption rates, enhancing reactivity control. Heterogeneous reactors separate fuel and moderator physically, enabling more precise control over neutron flux distribution and moderation by adjusting fuel arrangement and moderator properties. Control mechanisms in homogeneous reactors rely on soluble poisons and temperature feedback, while heterogeneous reactors utilize control rods and moderator level changes for dynamic reactivity management.

Efficiency and Power Output Comparison

Homogeneous reactors feature fuel dissolved in the moderator, promoting uniform neutron distribution that enhances fuel utilization efficiency but often limits power density due to coolant constraints. Heterogeneous reactors separate fuel and moderator physically, allowing higher power output with improved heat transfer and fuel arrangement optimization, resulting in greater thermal efficiency and power scaling. The intrinsic design of heterogeneous reactors generally leads to superior efficiency and power output compared to homogeneous reactors, especially in commercial power generation contexts.

Safety Features and Risk Assessment

Homogeneous reactors feature a uniform mixture of fuel and moderator in a liquid form, which enables continuous circulation and efficient heat removal, reducing hotspots and enhancing safety through inherent negative reactivity feedback mechanisms. Heterogeneous reactors separate fuel and moderator into distinct solid components, allowing for robust structural integrity but requiring complex control systems to manage localized temperature variations and prevent fuel damage. Risk assessment of homogeneous reactors emphasizes managing chemical toxicity and radiolysis, while heterogeneous reactors focus on mechanical failure and material degradation under irradiation stress.

Fuel Cycle and Waste Management

Homogeneous reactors dissolve fuel directly into the coolant, allowing for continuous reprocessing and easier removal of fission products, which streamlines the fuel cycle but poses challenges in corrosion management and isotope separation. Heterogeneous reactors maintain solid fuel elements in fixed arrangements, facilitating fuel inspection and replacement, with spent fuel requiring complex handling and longer-term storage due to higher radiation and thermal loads. Waste management in homogeneous reactors benefits from reduced solid waste volume and potential for transmutation, whereas heterogeneous reactors demand robust containment strategies to address spent fuel assemblies and long-lived radioactive waste.

Technological Applications and Industry Use

Homogeneous reactors, where fuel and moderator are mixed in a single phase, are commonly used in research and medical isotope production due to their efficient heat transfer and simpler control systems. Heterogeneous reactors, featuring separate fuel and moderator materials, dominate commercial power generation because of their enhanced safety, improved neutron economy, and adaptability to various fuel types. Industries such as nuclear power plants rely heavily on heterogeneous reactors like pressurized water reactors (PWRs) and boiling water reactors (BWRs) for large-scale electricity production and long operational lifespans.

Future Prospects and Research Directions

Future prospects of homogeneous reactors emphasize improved catalyst solubility, enhanced reaction control, and streamlined separation processes, enabling more efficient chemical manufacturing and green energy applications. Research directions focus on developing novel catalyst formulations, advanced computational modeling for reaction mechanisms, and scalable reactor designs to boost selectivity and reduce environmental impact. Heterogeneous reactors continue to evolve through innovations in catalyst surface engineering, integrated process intensification, and hybrid reactor systems combining the benefits of both phases for sustainable industrial processes.

Fuel-moderator mixture

Homogeneous reactors feature a uniform fuel-moderator mixture enhancing neutron economy and heat distribution, whereas heterogeneous reactors separate fuel and moderator to optimize neutron moderation and structural integrity.

Multiplication factor

Homogeneous reactors typically exhibit a more uniform neutron multiplication factor (k-effective) due to the even distribution of fissile material and moderator, while heterogeneous reactors often achieve higher multiplication factors by optimizing the spatial arrangement of fuel and moderator regions.

Core configuration

Homogeneous reactors feature a uniform mixture of fuel and moderator within the core, while heterogeneous reactors maintain a distinct physical separation between fuel elements and moderator materials in their core configuration.

Neutron flux distribution

Neutron flux distribution in homogeneous reactors is generally more uniform due to the consistent mixture of fuel and moderator, whereas heterogeneous reactors exhibit spatial flux variations caused by the distinct separation of fuel elements and moderator.

Coolant integration

Homogeneous reactors integrate coolant and fuel in a single phase improving heat transfer efficiency, whereas heterogeneous reactors separate coolant and fuel into distinct physical phases enhancing structural integrity and neutron economy.

Lattice structure

Homogeneous reactors feature a uniform lattice structure with fuel and moderator mixed together, whereas heterogeneous reactors have a distinct lattice arrangement separating fuel elements from the moderator for optimized neutron economy.

Criticality control

Criticality control in homogeneous reactors is achieved by uniformly distributing fissile material within the moderator, enabling precise reactivity adjustments, whereas heterogeneous reactors rely on spatial separation of fuel and moderator, allowing localized control and easier insertion of control materials.

Heat transfer uniformity

Homogeneous reactors offer more uniform heat transfer due to the consistent phase distribution within the reactor, while heterogeneous reactors experience localized hot spots and less uniform heat distribution because of phase segregation.

Moderator segregation

Homogeneous reactors mix the moderator and fuel uniformly for consistent neutron moderation, while heterogeneous reactors segregate the moderator and fuel physically to optimize neutron economy and thermalization efficiency.

Fuel reprocessing

Homogeneous reactors mix fuel and coolant for simplified fuel reprocessing and continuous recycling, whereas heterogeneous reactors separate fuel and coolant phases, requiring more complex fuel extraction and reprocessing techniques.

homogeneous reactor vs heterogeneous reactor Infographic

njnir.com

njnir.com