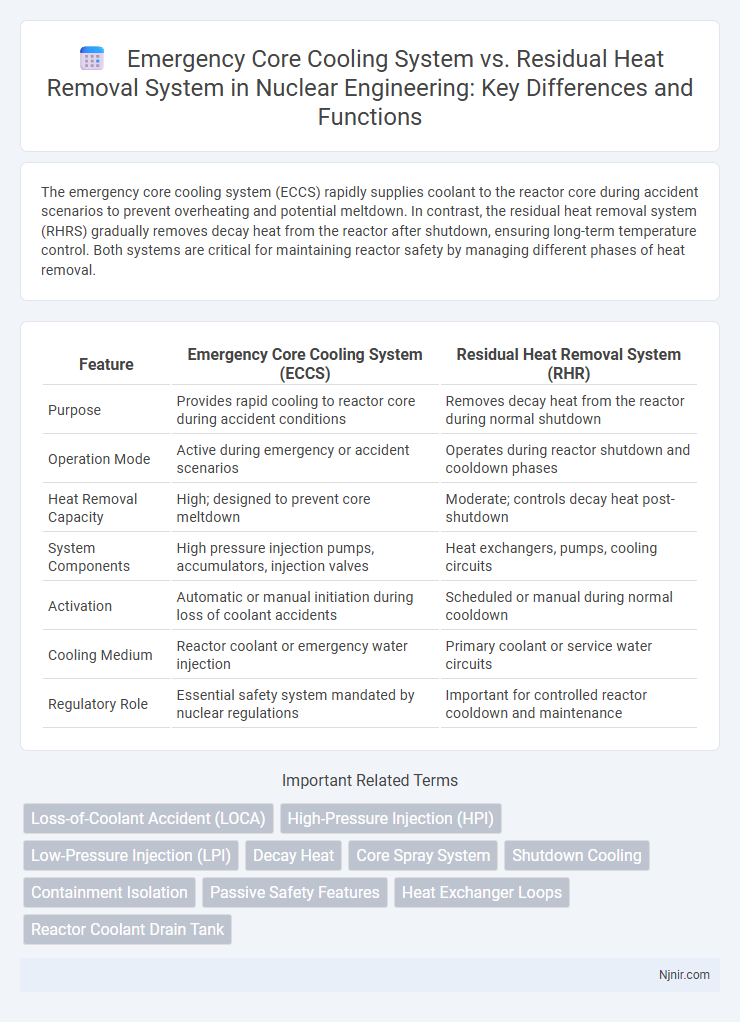

The emergency core cooling system (ECCS) rapidly supplies coolant to the reactor core during accident scenarios to prevent overheating and potential meltdown. In contrast, the residual heat removal system (RHRS) gradually removes decay heat from the reactor after shutdown, ensuring long-term temperature control. Both systems are critical for maintaining reactor safety by managing different phases of heat removal.

Table of Comparison

| Feature | Emergency Core Cooling System (ECCS) | Residual Heat Removal System (RHR) |

|---|---|---|

| Purpose | Provides rapid cooling to reactor core during accident conditions | Removes decay heat from the reactor during normal shutdown |

| Operation Mode | Active during emergency or accident scenarios | Operates during reactor shutdown and cooldown phases |

| Heat Removal Capacity | High; designed to prevent core meltdown | Moderate; controls decay heat post-shutdown |

| System Components | High pressure injection pumps, accumulators, injection valves | Heat exchangers, pumps, cooling circuits |

| Activation | Automatic or manual initiation during loss of coolant accidents | Scheduled or manual during normal cooldown |

| Cooling Medium | Reactor coolant or emergency water injection | Primary coolant or service water circuits |

| Regulatory Role | Essential safety system mandated by nuclear regulations | Important for controlled reactor cooldown and maintenance |

Overview of Emergency Core Cooling System (ECCS)

The Emergency Core Cooling System (ECCS) is designed to provide rapid cooling to the nuclear reactor core during loss-of-coolant accidents, preventing core damage and maintaining reactor safety. ECCS incorporates multiple subsystems including high-pressure injection, low-pressure injection, and core spray, each activated based on accident conditions to ensure effective heat removal. This system operates in tandem with the Residual Heat Removal System, which manages decay heat removal during shutdown conditions but is not designed for rapid accident response like the ECCS.

Overview of Residual Heat Removal System (RHRS)

The Residual Heat Removal System (RHRS) is a crucial safety feature in nuclear power plants designed to remove decay heat from the reactor core after shutdown, preventing overheating and potential core damage. Unlike the Emergency Core Cooling System (ECCS), which rapidly injects coolant during accident scenarios to prevent core meltdown, the RHRS operates continuously during normal shutdown and cooldown phases to maintain safe temperature levels. RHRS typically employs pumps, heat exchangers, and cooling loops to transfer residual heat to the ultimate heat sink, ensuring the reactor remains in a stable and controlled state post-operation.

Primary Functions: ECCS vs RHRS

The Emergency Core Cooling System (ECCS) primarily provides rapid injection of coolant into the reactor core during loss-of-coolant accidents to prevent core overheating and maintain nuclear fuel integrity. The Residual Heat Removal System (RHRS) focuses on removing decay heat from the reactor core during shutdown conditions to ensure safe temperature reduction. Both systems are crucial for reactor safety but operate at different stages and thermal conditions within the nuclear plant lifecycle.

System Design Principles and Components

The Emergency Core Cooling System (ECCS) is designed to provide rapid injection of coolant into the reactor core during loss-of-coolant accidents, featuring components like high-pressure injection pumps, accumulators, and core spray systems to maintain core integrity. In contrast, the Residual Heat Removal System (RHRS) focuses on removing decay heat from the reactor during shutdown conditions, utilizing heat exchangers, pumps, and cooling loops to ensure temperature control and prevent overheating. Both systems emphasize redundancy, reliability, and independence in their design principles to enhance nuclear safety and effective thermal management.

Operational Modes and Activation Triggers

The Emergency Core Cooling System (ECCS) activates during loss-of-coolant accidents (LOCA) to rapidly inject coolant and maintain reactor core temperature below critical limits, primarily operating in high-pressure and low-pressure injection modes. The Residual Heat Removal System (RHR) functions during shutdown and cooldown phases, removing decay heat through low-pressure, low-flow circulation, initiated when reactor power decreases below operational thresholds or during reactor shutdown. Both systems utilize sensor arrays detecting temperature, pressure, and coolant levels, but ECCS triggers are tied to rapid coolant loss events, whereas RHR activation responds to decay heat removal requirements.

Key Differences in Performance and Safety Objectives

The emergency core cooling system (ECCS) is designed to rapidly inject coolant into a reactor core during a loss-of-coolant accident to prevent fuel damage and core meltdown, prioritizing immediate safety and maintaining core integrity. In contrast, the residual heat removal system (RHRS) focuses on removing decay heat following reactor shutdown, ensuring long-term temperature control and preventing overheating in a less urgent but continuous safety function. ECCS operates under high-pressure, fast-response conditions, whereas RHRS functions primarily at lower pressures with sustained heat removal for stable cooldown, reflecting their distinct performance criteria and safety objectives.

Interaction with Other Nuclear Safety Systems

The Emergency Core Cooling System (ECCS) interfaces dynamically with the Residual Heat Removal System (RHRS) to ensure continuous core cooling and prevent overheating during reactor shutdown or accident conditions. ECCS activates during loss-of-coolant accidents by injecting coolant to maintain core integrity, while the RHRS removes decay heat once the reactor is subcritical, working synergistically to maintain safe temperatures. Both systems integrate with containment and instrumentation controls to provide comprehensive nuclear safety and minimize risk of core damage.

Regulatory Requirements and Compliance Standards

Emergency Core Cooling Systems (ECCS) must comply with strict regulatory requirements outlined by agencies such as the U.S. Nuclear Regulatory Commission (NRC) under 10 CFR Part 50.46, which mandates performance standards for maintaining reactor core integrity during postulated accident conditions. Residual Heat Removal (RHR) Systems are governed by complementary regulations ensuring effective decay heat removal during shutdown, with compliance standards emphasizing reliability and functional testing per ASME Section XI and IEEE standards. Both systems require rigorous documentation, periodic inspection, and adherence to plant-specific Technical Specifications to meet safety and operational compliance.

Common Challenges and Failure Modes

Emergency core cooling systems (ECCS) and residual heat removal systems (RHRS) face common challenges such as coolant leakage, pump failures, and valve malfunctions that can compromise heat removal efficiency. Both systems are vulnerable to sensor inaccuracies and control logic errors, leading to delayed or inadequate response during accident conditions. Corrosion, mechanical wear, and thermal stresses frequently contribute to component degradation, increasing the risk of system failure and impacting nuclear reactor safety.

Future Developments in ECCS and RHRS Technologies

Future developments in Emergency Core Cooling Systems (ECCS) focus on enhancing passive safety features and integrating advanced sensor technologies for real-time monitoring and automated response during reactor emergencies. Innovations in Residual Heat Removal Systems (RHRS) aim to improve thermal efficiency and reliability through modular designs and advanced heat exchanger materials that can withstand higher temperatures and radiation levels. Both ECCS and RHRS are increasingly incorporating digital twin technologies and AI-driven predictive maintenance to optimize performance and minimize downtime in next-generation nuclear reactors.

Loss-of-Coolant Accident (LOCA)

The Emergency Core Cooling System (ECCS) rapidly injects coolant to mitigate fuel damage during a Loss-of-Coolant Accident (LOCA), while the Residual Heat Removal System (RHR) maintains heat removal after initial coolant replenishment to prevent core overheating.

High-Pressure Injection (HPI)

High-Pressure Injection (HPI) plays a critical role in the Emergency Core Cooling System (ECCS) by rapidly supplying coolant at high pressure to prevent core damage during loss-of-coolant accidents, whereas the Residual Heat Removal System (RHR) primarily removes decay heat during shutdown or low-pressure conditions.

Low-Pressure Injection (LPI)

The Low-Pressure Injection (LPI) system, a critical component of the Emergency Core Cooling System (ECCS), rapidly delivers coolant to the reactor core during low-pressure conditions to prevent overheating, whereas the Residual Heat Removal System (RHR) primarily removes decay heat from the reactor coolant system after shutdown to maintain safe temperatures.

Decay Heat

The Emergency Core Cooling System (ECCS) rapidly injects coolant to prevent fuel damage during accidents, while the Residual Heat Removal System (RHRS) continuously removes decay heat during shutdown to maintain safe reactor temperatures.

Core Spray System

The Core Spray System is a critical component of the Emergency Core Cooling System, designed to deliver high-pressure water directly to the reactor core to prevent overheating, whereas the Residual Heat Removal System primarily removes decay heat under low-pressure conditions during cooldown.

Shutdown Cooling

The emergency core cooling system rapidly injects coolant to prevent core damage during accidents, while the residual heat removal system provides controlled shutdown cooling to remove decay heat from the reactor after shutdown.

Containment Isolation

The Emergency Core Cooling System (ECCS) ensures rapid reactor core cooling during accidents while the Residual Heat Removal System (RHR) manages decay heat removal during shutdown, both requiring precise containment isolation protocols to prevent radioactive release.

Passive Safety Features

Emergency core cooling systems employ active mechanisms for rapid coolant injection during crises, whereas residual heat removal systems primarily utilize passive safety features like natural circulation to dissipate decay heat without external power.

Heat Exchanger Loops

Emergency core cooling system heat exchanger loops rapidly remove decay heat during reactor emergencies, while residual heat removal system loops maintain safe temperatures during normal shutdown conditions.

Reactor Coolant Drain Tank

The Reactor Coolant Drain Tank in Emergency Core Cooling Systems (ECCS) collects and temporarily stores reactor coolant during emergency cooldown, while Residual Heat Removal (RHR) systems use this tank to facilitate heat extraction and maintain safe core temperature post-shutdown.

emergency core cooling system vs residual heat removal system Infographic

njnir.com

njnir.com