Reprocessing nuclear fuel recovers valuable fissile materials, reducing the volume and toxicity of high-level radioactive waste compared to direct disposal. This process enables recycling of plutonium and uranium for new fuel, enhancing resource utilization and energy sustainability. Direct disposal involves sealing spent fuel in geological repositories, prioritizing simplicity but requiring long-term containment strategies to isolate radioactivity from the environment.

Table of Comparison

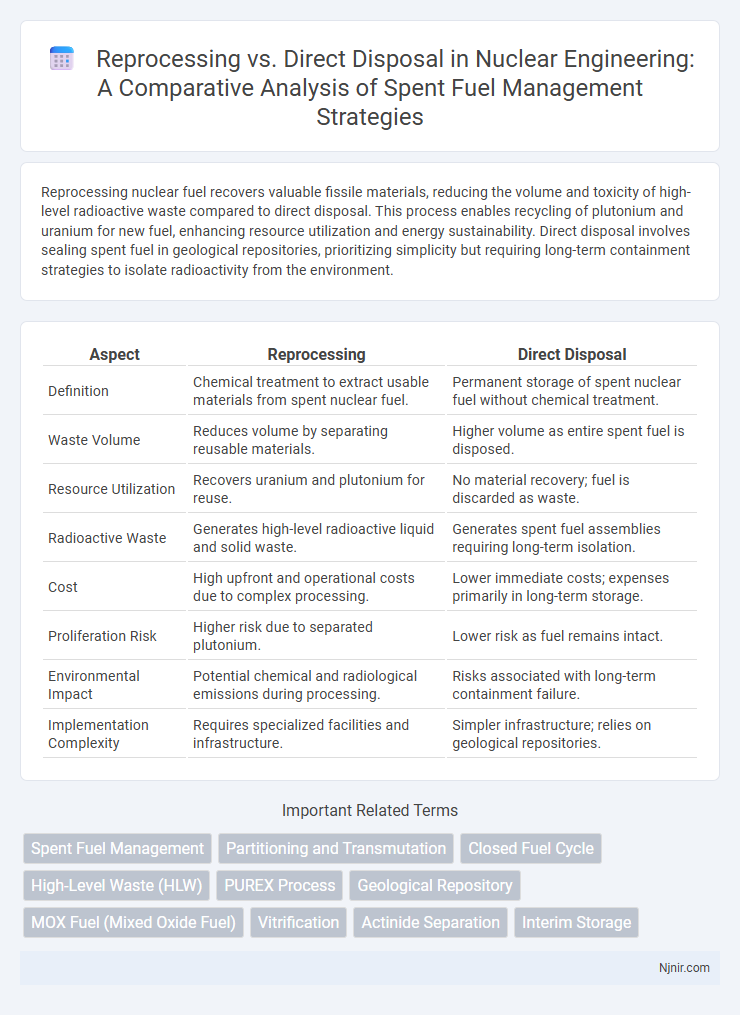

| Aspect | Reprocessing | Direct Disposal |

|---|---|---|

| Definition | Chemical treatment to extract usable materials from spent nuclear fuel. | Permanent storage of spent nuclear fuel without chemical treatment. |

| Waste Volume | Reduces volume by separating reusable materials. | Higher volume as entire spent fuel is disposed. |

| Resource Utilization | Recovers uranium and plutonium for reuse. | No material recovery; fuel is discarded as waste. |

| Radioactive Waste | Generates high-level radioactive liquid and solid waste. | Generates spent fuel assemblies requiring long-term isolation. |

| Cost | High upfront and operational costs due to complex processing. | Lower immediate costs; expenses primarily in long-term storage. |

| Proliferation Risk | Higher risk due to separated plutonium. | Lower risk as fuel remains intact. |

| Environmental Impact | Potential chemical and radiological emissions during processing. | Risks associated with long-term containment failure. |

| Implementation Complexity | Requires specialized facilities and infrastructure. | Simpler infrastructure; relies on geological repositories. |

Overview of Spent Nuclear Fuel Management

Spent nuclear fuel management involves two primary strategies: reprocessing and direct disposal. Reprocessing separates usable fissile materials like uranium and plutonium for recycling into new fuel, reducing waste volume and extending fuel supply. Direct disposal involves encapsulating spent fuel in stable containers for deep geological repository storage, emphasizing containment and long-term isolation without recovering materials.

Fundamentals of Reprocessing

Reprocessing involves separating usable fissile materials like uranium and plutonium from spent nuclear fuel to recycle them into new fuel, significantly reducing the volume and radiotoxicity of high-level waste. Key steps include cutting, dissolution, chemical separation via PUREX (Plutonium Uranium Redox EXtraction) process, and conversion of recovered materials into fresh fuel assemblies. This approach contrasts with direct disposal, which entails placing spent fuel into deep geological repositories without material recovery, resulting in higher long-term radiotoxicity and resource loss.

Fundamentals of Direct Disposal

Direct disposal involves the permanent placement of spent nuclear fuel into a geologically stable repository without undergoing chemical reprocessing. This method eliminates the complexities and costs associated with separating usable fissile materials, relying on robust containment systems and multi-barrier geologic isolation to prevent radionuclide migration. The strategy emphasizes long-term safety and environmental protection by leveraging natural geological formations and engineered barriers to isolate radioactive waste from the biosphere.

Comparative Environmental Impacts

Reprocessing spent nuclear fuel recovers usable materials, reducing waste volume and long-term radiotoxicity compared to direct disposal, which isolates all nuclear waste without material recovery. Reprocessing lowers the demand for uranium mining, thereby decreasing environmental degradation and greenhouse gas emissions associated with fuel production. However, reprocessing involves complex chemical treatments that produce secondary waste streams requiring secure management to mitigate environmental contamination risks.

Waste Volume and Radiotoxicity Reduction

Reprocessing spent nuclear fuel significantly reduces waste volume by recovering usable materials such as uranium and plutonium, leaving behind a smaller amount of high-level waste compared to direct disposal. This process also decreases the long-term radiotoxicity of the waste, as the separated actinides can be recycled or transmuted, reducing the hazard period from hundreds of thousands to a few hundred years. Direct disposal, by contrast, involves placing spent fuel directly into geological repositories, resulting in larger waste volumes with persistent high radiotoxicity requiring secure containment for extensive timeframes.

Proliferation Risks and Security Concerns

Reprocessing spent nuclear fuel increases proliferation risks by separating plutonium, which can be diverted for nuclear weapons, whereas direct disposal reduces this risk by keeping fissile materials contained within the waste. Security concerns in reprocessing facilities are heightened due to the need for stringent safeguards and monitoring to prevent theft or sabotage of nuclear materials. Direct disposal strategies typically require less intensive security measures, as radioactive waste remains immobilized and less accessible for unauthorized use.

Economic Considerations and Cost Analysis

Reprocessing spent nuclear fuel involves high upfront capital investment but can reduce long-term disposal costs by recovering valuable fissile materials and decreasing waste volume. Direct disposal requires lower initial costs but may lead to larger, more expensive geological repositories and increased environmental monitoring expenses over time. Economic considerations favor reprocessing in countries with advanced nuclear infrastructure seeking fuel sustainability, while direct disposal remains cost-effective for smaller programs or limited budgets.

Technological Challenges and Innovations

Reprocessing spent nuclear fuel involves complex chemical separation techniques to extract usable isotopes, facing challenges such as managing highly radioactive materials and minimizing waste volume. Innovations like advanced solvent extraction methods and modular recycling facilities improve efficiency and safety in reprocessing operations. Direct disposal bypasses these steps, but technological barriers remain in developing robust geological repositories with long-term containment and monitoring systems to prevent environmental contamination.

Regulatory and Policy Frameworks

Regulatory and policy frameworks for reprocessing versus direct disposal emphasize environmental safety, radioactive waste management, and non-proliferation. Countries with advanced nuclear programs implement stringent regulations mandating reprocessing to reduce high-level waste volume, recover valuable fissile materials, and limit long-term radiotoxicity. In contrast, other jurisdictions prioritize direct disposal policies based on geological repository availability, economic considerations, and minimizing proliferation risks by avoiding separated plutonium.

Future Perspectives in Spent Fuel Management

Future perspectives in spent fuel management increasingly favor advanced reprocessing technologies to recover valuable materials such as plutonium and uranium, reducing nuclear waste volume and enhancing resource sustainability. Emerging methods aim to improve separation efficiency and minimize environmental impact, aligning with circular economy principles and long-term repository safety. Direct disposal remains a practical solution for certain fuel types, but innovations in reprocessing are driving a shift toward integrating closed fuel cycles for improved waste management and energy security.

Spent Fuel Management

Spent fuel management involves reprocessing to recover usable materials and reduce waste volume, while direct disposal emphasizes secure containment and isolation of highly radioactive spent fuel in geological repositories.

Partitioning and Transmutation

Partitioning and Transmutation technologies enable the reduction of high-level nuclear waste volume and radiotoxicity by separating and converting long-lived isotopes, making reprocessing a more sustainable alternative to direct disposal.

Closed Fuel Cycle

The Closed Fuel Cycle enhances sustainability by reprocessing spent nuclear fuel to recover usable materials, reducing waste volume and radiotoxicity compared to direct disposal.

High-Level Waste (HLW)

Reprocessing High-Level Waste (HLW) reduces volume and recovers valuable fissile materials, whereas direct disposal isolates HLW without material recovery, impacting long-term storage requirements and environmental risk.

PUREX Process

The PUREX process efficiently separates uranium and plutonium from spent nuclear fuel for reprocessing, reducing waste volume compared to direct disposal methods.

Geological Repository

Geological repositories offer a long-term, secure solution for disposing high-level radioactive waste, with reprocessing reducing waste volume and toxicity before final disposal compared to direct disposal methods.

MOX Fuel (Mixed Oxide Fuel)

MOX fuel reprocessing reduces nuclear waste volume, recovers valuable plutonium and uranium for reuse, and enhances resource efficiency compared to direct disposal, which permanently isolates spent fuel without material recovery.

Vitrification

Vitrification enhances nuclear waste management by immobilizing high-level waste in glass, offering superior containment and reduced environmental risks compared to direct disposal methods.

Actinide Separation

Actinide separation during reprocessing significantly reduces radiotoxicity and heat load in spent nuclear fuel compared to direct disposal, enhancing waste management efficiency and repository safety.

Interim Storage

Interim storage serves as a critical solution for safely holding spent nuclear fuel between reactor discharge and final reprocessing or direct disposal, optimizing waste management efficiency and reducing environmental risks.

reprocessing vs direct disposal Infographic

njnir.com

njnir.com