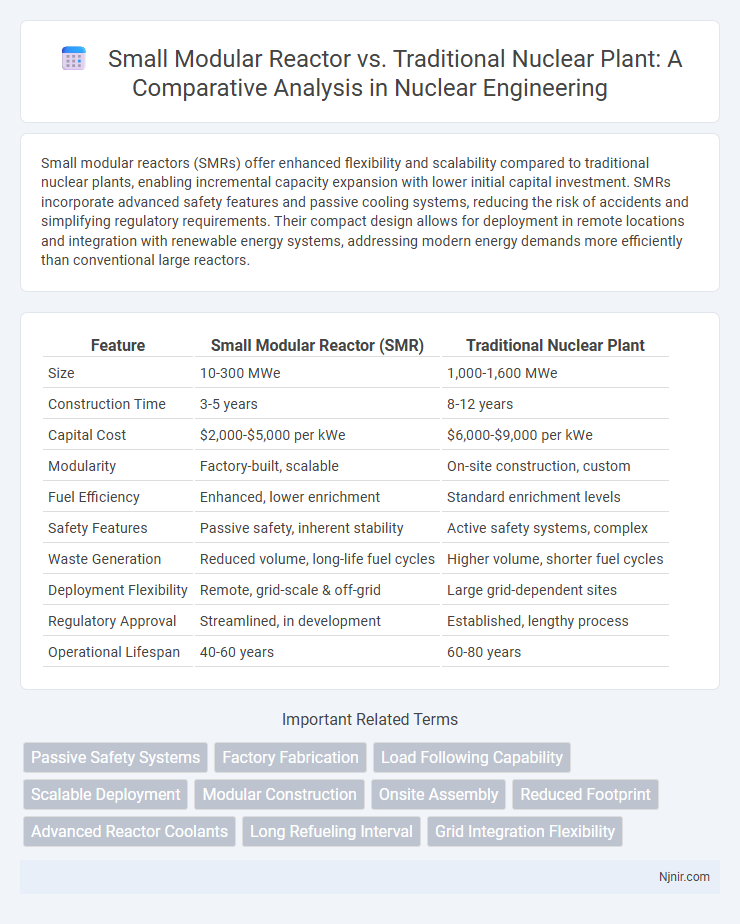

Small modular reactors (SMRs) offer enhanced flexibility and scalability compared to traditional nuclear plants, enabling incremental capacity expansion with lower initial capital investment. SMRs incorporate advanced safety features and passive cooling systems, reducing the risk of accidents and simplifying regulatory requirements. Their compact design allows for deployment in remote locations and integration with renewable energy systems, addressing modern energy demands more efficiently than conventional large reactors.

Table of Comparison

| Feature | Small Modular Reactor (SMR) | Traditional Nuclear Plant |

|---|---|---|

| Size | 10-300 MWe | 1,000-1,600 MWe |

| Construction Time | 3-5 years | 8-12 years |

| Capital Cost | $2,000-$5,000 per kWe | $6,000-$9,000 per kWe |

| Modularity | Factory-built, scalable | On-site construction, custom |

| Fuel Efficiency | Enhanced, lower enrichment | Standard enrichment levels |

| Safety Features | Passive safety, inherent stability | Active safety systems, complex |

| Waste Generation | Reduced volume, long-life fuel cycles | Higher volume, shorter fuel cycles |

| Deployment Flexibility | Remote, grid-scale & off-grid | Large grid-dependent sites |

| Regulatory Approval | Streamlined, in development | Established, lengthy process |

| Operational Lifespan | 40-60 years | 60-80 years |

Introduction to Small Modular Reactors and Traditional Nuclear Plants

Small modular reactors (SMRs) are advanced nuclear reactors designed to be smaller in size, with power outputs typically under 300 megawatts, enabling modular construction and enhanced safety features compared to traditional nuclear plants. Traditional nuclear plants usually generate between 1,000 and 1,600 megawatts, relying on large-scale reactors with complex infrastructure and longer construction timelines. SMRs offer scalable energy solutions with passive safety systems and reduced onsite construction, addressing challenges faced by conventional large nuclear facilities.

Design Differences between SMRs and Conventional Reactors

Small Modular Reactors (SMRs) feature compact, factory-fabricated modules with passive safety systems and simplified designs that enable scalability and flexible deployment, contrasting with Traditional Nuclear Plants which rely on large, site-built reactors with complex active safety mechanisms. SMRs utilize advanced materials and modular components allowing for reduced construction times and lower initial capital costs, whereas conventional reactors demand extensive on-site assembly and prolonged timelines. The integrated design of SMRs enhances thermal efficiency and safety margins by employing inherent cooling features absent in most traditional large-scale nuclear facilities.

Safety Features: SMRs versus Traditional Plants

Small Modular Reactors (SMRs) incorporate advanced passive safety systems that reduce the reliance on active components and human intervention in emergencies, enhancing overall safety compared to traditional nuclear plants. SMRs utilize smaller cores and lower power levels, which minimize the risk of meltdown and improve heat dissipation through natural circulation. Traditional nuclear plants often depend on complex cooling systems and active safety mechanisms, increasing vulnerability to mechanical failures and requiring extensive safety infrastructure.

Economic Considerations: Cost, Financing, and Scalability

Small Modular Reactors (SMRs) offer lower upfront capital costs compared to traditional nuclear plants, enhancing financing feasibility through reduced financial risk and shorter construction timelines. The modular design of SMRs enables scalable deployment, allowing incremental capacity additions aligned with demand, which contrasts with the large, one-time investment required for conventional plants. Economies of scale in traditional plants benefit from bulk construction but face challenges in cost overruns and financing complexity, where SMRs' standardized manufacturing promotes cost predictability and flexible investment strategies.

Construction Timeframes and Deployment Flexibility

Small Modular Reactors (SMRs) offer significantly reduced construction timeframes compared to traditional nuclear plants, often completing in 3 to 5 years versus 7 to 10 years for large reactors. The modular design allows prefabrication in controlled factory environments, minimizing on-site delays and enabling scalable, phased deployment to meet evolving energy demands. SMRs provide enhanced deployment flexibility, suitable for remote locations and smaller grids, contrasting with the large-scale infrastructure and extensive site preparation required for conventional nuclear power stations.

Operational Efficiency and Performance

Small Modular Reactors (SMRs) offer enhanced operational efficiency through modular construction, allowing for incremental capacity additions and reduced construction time compared to Traditional Nuclear Plants, which are typically large-scale and require longer build periods. SMRs benefit from passive safety systems and simplified design, resulting in lower operational costs and higher availability factors, while Traditional Nuclear Plants demand extensive maintenance and have complexity-driven downtime. Performance-wise, SMRs provide greater flexibility in grid integration and load-following capabilities, optimizing energy output in variable demand scenarios better than traditional baseload-focused reactors.

Waste Management and Environmental Impact

Small Modular Reactors (SMRs) generate less nuclear waste per unit of energy compared to traditional nuclear plants due to their advanced fuel efficiency and modular design, which facilitates more effective waste processing and recycling. The smaller scale of SMRs results in reduced land use and lower environmental disruption, while advanced safety features decrease the risk of radioactive contamination. Traditional nuclear plants produce larger volumes of spent fuel requiring extensive long-term storage solutions, often posing higher environmental risks in the event of accidents or natural disasters.

Regulatory Frameworks and Licensing Processes

Small Modular Reactors (SMRs) face evolving regulatory frameworks designed to address their unique modularity and smaller scale, enabling potentially faster licensing compared to Traditional Nuclear Plants, which are subject to more established and often lengthier regulatory processes. Regulatory agencies like the U.S. Nuclear Regulatory Commission (NRC) are developing tailored review criteria for SMRs to streamline design certification, construction, and operation within rigorous safety standards. The modular construction of SMRs allows for phased licensing, contrasting with the comprehensive, single-phase licensing of traditional plants, influencing project timelines and capital expenditure recovery.

Applications: Energy Markets and Grid Integration

Small Modular Reactors (SMRs) offer scalable energy solutions suited for remote or smaller grids where traditional nuclear plants face limitations due to size and infrastructure demands. Their flexibility enables easier integration into diverse energy markets, facilitating load-following capabilities and supporting renewable energy complements. Traditional nuclear plants provide high-capacity baseload power but struggle with grid adaptability and incremental scaling compared to SMRs.

Future Outlook: Advancements and Industry Trends

Small Modular Reactors (SMRs) offer a transformative future outlook in nuclear energy, with advancements emphasizing enhanced safety features, modular construction, and scalability that traditional nuclear plants lack. Industry trends reveal increased investment in SMRs due to their potential for lower upfront capital costs, reduced construction times, and adaptability to grid demands or remote locations. Regulatory bodies and energy market analysts predict SMRs will play a pivotal role in decarbonizing energy sectors, complementing renewables while overcoming challenges faced by conventional large-scale reactors.

Passive Safety Systems

Small modular reactors incorporate advanced passive safety systems that rely on natural circulation and gravity to maintain cooling without external power, contrasting with traditional nuclear plants that typically depend on active mechanical systems for safety.

Factory Fabrication

Small modular reactors enable streamlined factory fabrication processes, reducing construction time and costs compared to traditional nuclear plants assembled on-site.

Load Following Capability

Small Modular Reactors offer superior load following capability compared to Traditional Nuclear Plants, enabling more flexible and efficient integration with renewable energy sources.

Scalable Deployment

Small Modular Reactors enable scalable deployment through modular construction and incremental capacity additions, unlike traditional nuclear plants that require large, fixed-scale builds with longer construction timelines.

Modular Construction

Small modular reactors utilize prefabricated, factory-built modules for faster, cost-effective construction compared to the large-scale, on-site assembly required for traditional nuclear plants.

Onsite Assembly

Small Modular Reactors feature streamlined onsite assembly with prefabricated components, reducing construction time and costs compared to the extensive onsite construction required for Traditional Nuclear Plants.

Reduced Footprint

Small Modular Reactors (SMRs) offer a significantly reduced footprint compared to traditional nuclear plants by utilizing compact designs that require less land and infrastructure, enabling flexible deployment and minimized environmental impact.

Advanced Reactor Coolants

Small Modular Reactors utilize advanced coolants such as molten salt or lead-bismuth eutectic, offering higher thermal efficiency and improved safety compared to the conventional water-based coolant systems in traditional nuclear plants.

Long Refueling Interval

Small modular reactors offer significantly longer refueling intervals than traditional nuclear plants, enhancing operational efficiency and reducing downtime.

Grid Integration Flexibility

Small Modular Reactors offer superior grid integration flexibility compared to traditional nuclear plants by enabling modular deployment, rapid ramping, and easier adaptation to fluctuating energy demands.

Small Modular Reactor vs Traditional Nuclear Plant Infographic

njnir.com

njnir.com