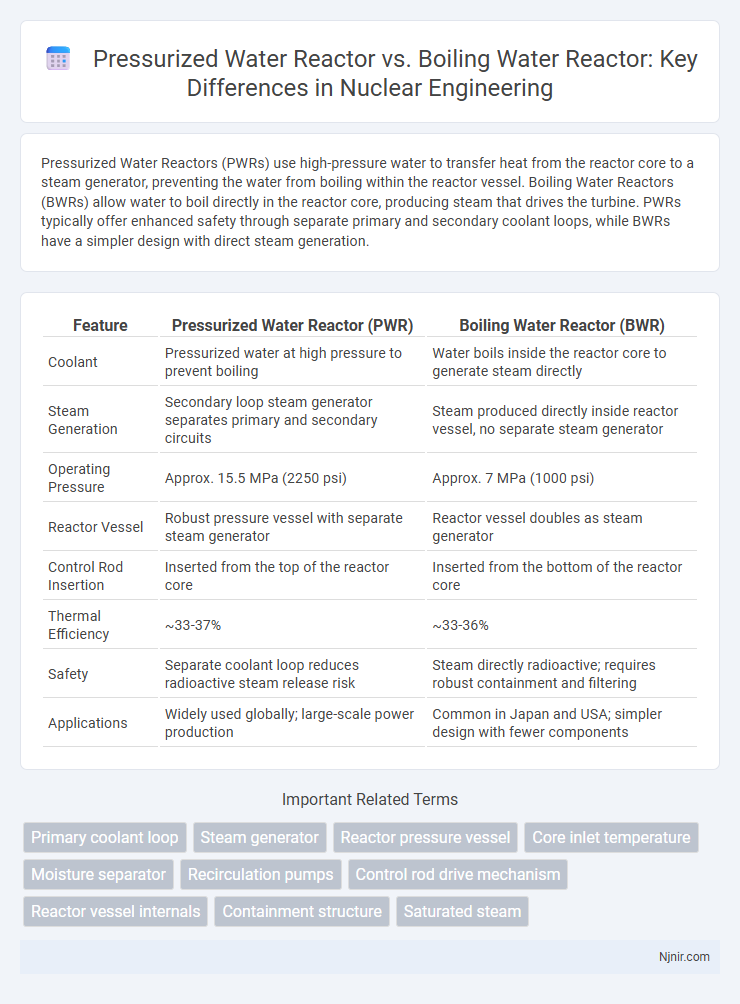

Pressurized Water Reactors (PWRs) use high-pressure water to transfer heat from the reactor core to a steam generator, preventing the water from boiling within the reactor vessel. Boiling Water Reactors (BWRs) allow water to boil directly in the reactor core, producing steam that drives the turbine. PWRs typically offer enhanced safety through separate primary and secondary coolant loops, while BWRs have a simpler design with direct steam generation.

Table of Comparison

| Feature | Pressurized Water Reactor (PWR) | Boiling Water Reactor (BWR) |

|---|---|---|

| Coolant | Pressurized water at high pressure to prevent boiling | Water boils inside the reactor core to generate steam directly |

| Steam Generation | Secondary loop steam generator separates primary and secondary circuits | Steam produced directly inside reactor vessel, no separate steam generator |

| Operating Pressure | Approx. 15.5 MPa (2250 psi) | Approx. 7 MPa (1000 psi) |

| Reactor Vessel | Robust pressure vessel with separate steam generator | Reactor vessel doubles as steam generator |

| Control Rod Insertion | Inserted from the top of the reactor core | Inserted from the bottom of the reactor core |

| Thermal Efficiency | ~33-37% | ~33-36% |

| Safety | Separate coolant loop reduces radioactive steam release risk | Steam directly radioactive; requires robust containment and filtering |

| Applications | Widely used globally; large-scale power production | Common in Japan and USA; simpler design with fewer components |

Introduction to Nuclear Reactors

Pressurized Water Reactors (PWRs) and Boiling Water Reactors (BWRs) are two primary types of light-water nuclear reactors used for electricity generation worldwide. PWRs maintain water under high pressure to prevent boiling, using a primary loop to transfer heat to a secondary loop that generates steam, whereas BWRs allow water to boil directly in the reactor core, producing steam to drive the turbine. The design differences impact reactor safety, efficiency, and complexity, with PWRs dominating global installations due to their robust pressure boundary and BWRs offering simplified systems with direct steam generation.

Fundamental Principles of PWR and BWR

Pressurized Water Reactors (PWRs) maintain water under high pressure to prevent boiling in the reactor core, using a primary loop to transfer heat to a secondary loop that generates steam for turbines. Boiling Water Reactors (BWRs) allow water to boil directly in the reactor core, producing steam that drives the turbine without a secondary loop. The fundamental principle of PWRs emphasizes pressurized coolant circulation to separate radioactive water from the turbine, whereas BWRs integrate steam generation within the reactor vessel, simplifying the system but requiring direct steam handling.

Core Design Differences

Pressurized Water Reactors (PWRs) utilize a core design where water coolant is kept under high pressure to prevent boiling, maintaining liquid state at high temperatures and enabling heat transfer through a secondary loop. Boiling Water Reactors (BWRs) have a core design that allows water to boil directly in the reactor vessel, producing steam that drives the turbine without a secondary loop. The core structure in PWRs typically includes a higher number of smaller fuel rods arranged in a tighter lattice, while BWR cores have larger spacing between fuel rods to facilitate steam formation within the reactor core.

Heat Transfer Mechanisms

Pressurized Water Reactors (PWRs) utilize a primary circuit where water is kept under high pressure to prevent boiling, transferring heat to a secondary circuit via steam generators. Boiling Water Reactors (BWRs) allow water to boil directly in the reactor core, producing steam that drives the turbine without a secondary loop. Heat transfer in PWRs relies on conduction and convection within the pressurized coolant, while BWRs depend on phase change heat transfer with steam formation enhancing thermal efficiency.

Steam Generation Processes

Pressurized Water Reactors (PWRs) use a primary loop where water is kept under high pressure to prevent boiling, transferring heat to a secondary loop where steam is generated for the turbine. Boiling Water Reactors (BWRs) allow water to boil directly in the reactor core, producing steam within the reactor vessel that drives the turbine. The key difference lies in PWRs separating the steam generation from the reactor core via a heat exchanger, while BWRs integrate steam production directly in the core.

Safety Systems Comparison

Pressurized Water Reactors (PWRs) utilize a primary cooling loop with high-pressure water to prevent boiling, ensuring core temperature regulation and reducing the risk of radioactive release. Boiling Water Reactors (BWRs) allow water to boil directly in the reactor vessel, requiring robust steam separation and containment systems to manage steam quality and mitigate potential radioactivity. PWR safety systems emphasize multiple redundant cooling loops and pressurizers, while BWRs rely on advanced emergency core cooling and containment isolation technologies to maintain reactor stability under transient conditions.

Fuel Utilization and Efficiency

Pressurized Water Reactors (PWRs) typically achieve higher fuel utilization by maintaining fuel integrity under higher pressure, allowing longer fuel cycles and improved neutron economy. Boiling Water Reactors (BWRs) operate with direct boiling in the core, resulting in lower fuel burnup but simpler design and operation. PWRs generally exhibit greater thermal efficiency around 33-37%, while BWR efficiency ranges from 32-34% due to differences in coolant temperature and pressure conditions.

Operational Flexibility and Control

Pressurized Water Reactors (PWRs) offer superior operational flexibility by maintaining a stable coolant pressure that prevents boiling, enabling precise control over reactor power output through adjustments in coolant flow and control rod positions. Boiling Water Reactors (BWRs) allow for direct steam generation within the reactor core, providing a more responsive power control due to real-time feedback from steam quality and flow rate changes. PWRs typically experience slower load-following capabilities compared to BWRs, which can rapidly adjust power levels, making BWRs advantageous in grids with variable electricity demand.

Economic and Maintenance Considerations

Pressurized Water Reactors (PWRs) generally have higher initial construction costs due to more complex coolant systems but benefit from standardized designs that lower maintenance expenses over time. Boiling Water Reactors (BWRs) feature simpler reactor designs with direct steam generation, resulting in reduced capital costs but potentially higher maintenance costs stemming from more frequent inspections and component replacements. Economic considerations must weigh PWRs' longer operational cycles and lower maintenance intensity against BWRs' lower upfront investment but increased upkeep requirements.

Global Deployment and Industry Trends

Pressurized Water Reactors (PWRs) dominate global nuclear power generation, representing about two-thirds of operational reactors worldwide due to their proven safety and efficiency in countries like the United States, France, and Japan. Boiling Water Reactors (BWRs), while less prevalent, maintain a significant presence with approximately one-third of reactors, favored in regions prioritizing simpler designs such as Japan and parts of Europe. Industry trends emphasize advancements in PWR technology with modular designs and extended fuel cycles, while BWR development focuses on improved control systems and enhanced safety features to meet evolving regulatory standards.

Primary coolant loop

Pressurized water reactors maintain the primary coolant loop under high pressure to prevent boiling, while boiling water reactors allow the coolant to boil directly in the reactor core, producing steam for the turbine.

Steam generator

Pressurized water reactors use a steam generator to transfer heat from the primary reactor coolant to a secondary loop, whereas boiling water reactors produce steam directly in the reactor vessel, eliminating the need for a separate steam generator.

Reactor pressure vessel

The pressurized water reactor (PWR) features a robust reactor pressure vessel designed to withstand high pressure to keep water in a liquid state, while the boiling water reactor (BWR) has a reactor pressure vessel engineered to allow water to boil inside, generating steam directly within the vessel.

Core inlet temperature

Pressurized water reactors maintain a core inlet temperature around 290degC under high pressure to prevent boiling, whereas boiling water reactors have a lower core inlet temperature near 230degC, allowing the coolant to boil within the reactor core.

Moisture separator

Pressurized Water Reactors use moisture separators to remove steam moisture before turbine entry, enhancing efficiency, while Boiling Water Reactors typically rely on in-turbine moisture separation methods.

Recirculation pumps

Pressurized Water Reactors utilize internal recirculation pumps to maintain coolant flow under high pressure, whereas Boiling Water Reactors employ external recirculation pumps to circulate water through the reactor core and steam separators.

Control rod drive mechanism

Pressurized Water Reactors (PWRs) use control rod drive mechanisms located outside the reactor vessel allowing for robust maintenance, whereas Boiling Water Reactors (BWRs) employ control rod drives inserted through the bottom of the reactor vessel facilitating precise neutron flux control within the core.

Reactor vessel internals

Pressurized Water Reactor (PWR) vessel internals feature a robust core barrel and baffle assembly designed to maintain structural integrity under high pressure, while Boiling Water Reactor (BWR) vessel internals include separators and steam dryers to efficiently manage steam quality and flow within the reactor vessel.

Containment structure

Pressurized Water Reactors (PWRs) utilize a robust, large containment structure designed to withstand high pressure and prevent radioactive release, whereas Boiling Water Reactors (BWRs) feature a more compact containment structure integrating the reactor vessel and steam separation components to efficiently manage steam generation and pressure.

Saturated steam

Pressurized water reactors produce saturated steam indirectly by heating water under high pressure in the primary loop, while boiling water reactors generate saturated steam directly within the reactor core by boiling water at lower pressure.

pressurized water reactor vs boiling water reactor Infographic

njnir.com

njnir.com