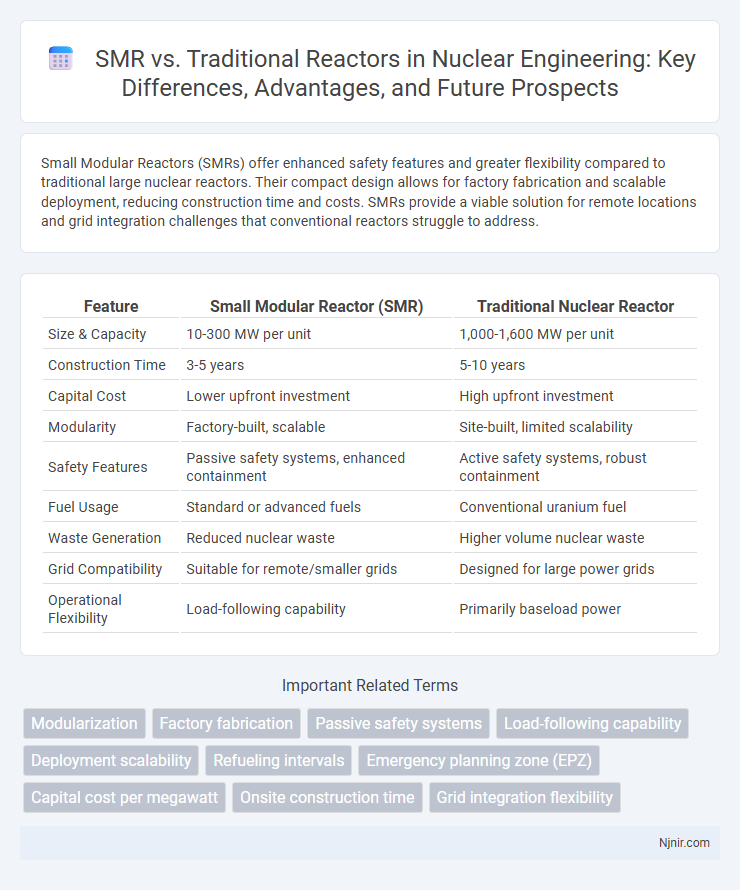

Small Modular Reactors (SMRs) offer enhanced safety features and greater flexibility compared to traditional large nuclear reactors. Their compact design allows for factory fabrication and scalable deployment, reducing construction time and costs. SMRs provide a viable solution for remote locations and grid integration challenges that conventional reactors struggle to address.

Table of Comparison

| Feature | Small Modular Reactor (SMR) | Traditional Nuclear Reactor |

|---|---|---|

| Size & Capacity | 10-300 MW per unit | 1,000-1,600 MW per unit |

| Construction Time | 3-5 years | 5-10 years |

| Capital Cost | Lower upfront investment | High upfront investment |

| Modularity | Factory-built, scalable | Site-built, limited scalability |

| Safety Features | Passive safety systems, enhanced containment | Active safety systems, robust containment |

| Fuel Usage | Standard or advanced fuels | Conventional uranium fuel |

| Waste Generation | Reduced nuclear waste | Higher volume nuclear waste |

| Grid Compatibility | Suitable for remote/smaller grids | Designed for large power grids |

| Operational Flexibility | Load-following capability | Primarily baseload power |

Overview of SMRs and Traditional Nuclear Reactors

Small Modular Reactors (SMRs) are compact nuclear power plants designed for modular construction, offering enhanced safety features and lower upfront capital costs compared to traditional nuclear reactors. Traditional reactors, typically large-scale facilities exceeding 1,000 megawatts electric (MWe), rely on established light-water reactor technology and require extensive construction times and complex infrastructure. SMRs, with power outputs generally below 300 MWe, enable flexible deployment in remote locations and provide scalable clean energy solutions with reduced operational risk.

Design Differences: SMR vs Traditional Reactor

Small Modular Reactors (SMRs) feature a compact, factory-fabricated design that enhances scalability and reduces construction time compared to traditional large-scale nuclear reactors. SMRs use passive safety systems relying on natural circulation and gravity, whereas traditional reactors typically require active safety mechanisms with multiple mechanical components. The modular approach of SMRs allows for incremental capacity increases and flexible deployment in remote or smaller grids, contrasting with the centralized, large-capacity design of conventional reactors.

Safety Features and Risk Mitigation

Small Modular Reactors (SMRs) incorporate advanced passive safety systems that operate without human intervention or external power, significantly reducing the risk of catastrophic failure compared to traditional reactors. Their compact design limits the amount of radioactive material at risk, minimizing potential accident consequences and enhancing containment integrity. Enhanced seismic resilience, modular construction, and inherent emergency cooling capabilities further improve SMRs' overall safety profile and risk mitigation strategies.

Cost Comparison: Capital and Operational Expenditure

Small Modular Reactors (SMRs) typically have lower initial capital expenditure compared to traditional large reactors due to modular construction and factory fabrication, which reduces onsite labor and construction timelines. Operational expenditure for SMRs can also be more cost-effective as they benefit from standardized designs, easier maintenance, and scalability, allowing utilities to add capacity incrementally based on demand. However, economies of scale favor traditional reactors for large-scale power generation, potentially resulting in lower per-MW costs once fully operational.

Scalability and Deployment Flexibility

Small Modular Reactors (SMRs) offer enhanced scalability compared to traditional reactors by enabling incremental capacity additions through factory-built modules, which facilitates faster deployment and reduced upfront capital costs. Their compact design allows for flexible siting options, including locations unsuitable for large reactors, supporting distributed generation and integration with renewable energy sources. This deployment flexibility accelerates project timelines and adapts to varying grid demands, making SMRs ideal for remote areas and smaller electric grids.

Fuel Utilization and Waste Management

Small Modular Reactors (SMRs) enhance fuel utilization by operating at higher burnup rates and supporting advanced fuel cycles compared to traditional reactors, resulting in more efficient energy extraction from nuclear fuel. SMRs often incorporate passive safety systems that reduce the volume and toxicity of nuclear waste, facilitating easier waste management and disposal. The modular design allows for potential integration of recycling technologies, further minimizing waste generation and improving long-term sustainability.

Regulatory and Licensing Challenges

Small Modular Reactors (SMRs) face distinct regulatory and licensing challenges compared to traditional reactors due to their innovative designs and smaller scale, which often fall outside existing regulatory frameworks established for large reactors. The lack of standardized international guidelines and the need for tailored safety evaluations increase the complexity and duration of licensing processes for SMRs. Regulatory bodies are working to adapt and streamline approval pathways to address these challenges while ensuring rigorous safety and environmental standards are met.

Grid Integration and Energy Demand Matching

Small Modular Reactors (SMRs) offer enhanced grid integration capabilities compared to traditional reactors due to their modular design and flexible output, enabling easier scalability and load following to match variable energy demand. Their smaller size and advanced control systems allow rapid adjustment of power generation, optimizing grid stability and accommodating renewable energy fluctuations. This adaptability reduces the need for costly grid upgrades and improves overall efficiency in balancing supply with dynamic regional energy needs.

Environmental Impact Assessment

Small Modular Reactors (SMRs) offer a significantly reduced environmental impact compared to traditional reactors due to their smaller physical footprint and enhanced safety features that minimize radioactive waste production. Lifecycle greenhouse gas emissions of SMRs are substantially lower, supporting global decarbonization efforts more efficiently than conventional nuclear plants. Environmental Impact Assessments highlight SMRs' potential for reduced water consumption and less land disruption, positioning them as a sustainable alternative in nuclear energy generation.

Future Prospects and Industry Adoption

Small Modular Reactors (SMRs) offer flexible, scalable nuclear power solutions with lower upfront capital costs compared to traditional large reactors, making them attractive for future energy markets and remote applications. Industry adoption is accelerating, driven by advancements in passive safety features, streamlined construction timelines, and supportive regulatory frameworks, especially in regions targeting carbon-neutral energy transitions. As global demand for clean energy rises, SMRs are positioned to complement renewables and expand nuclear capacity with enhanced operational efficiency and grid integration potential.

Modularization

Small Modular Reactors (SMRs) offer enhanced modularization through factory fabrication and scalable deployment compared to traditional large-scale nuclear reactors.

Factory fabrication

Small Modular Reactors (SMRs) utilize factory fabrication to enable controlled manufacturing environments, reduce on-site construction time, and enhance quality assurance compared to traditional reactors.

Passive safety systems

Small Modular Reactors (SMRs) enhance passive safety by utilizing natural circulation and inherent heat removal mechanisms that reduce reliance on active components compared to traditional reactors.

Load-following capability

Small modular reactors (SMRs) offer superior load-following capability compared to traditional reactors due to their smaller size, modular design, advanced control systems, and faster response times, enabling more flexible adjustment to grid demand fluctuations.

Deployment scalability

Small Modular Reactors (SMRs) offer greater deployment scalability than traditional reactors due to their compact size, modular design, and shorter construction times enabling phased capacity expansion and flexible site placement.

Refueling intervals

Small Modular Reactors (SMRs) typically offer refueling intervals of 2 to 5 years compared to traditional reactors that require refueling every 12 to 24 months.

Emergency planning zone (EPZ)

Small Modular Reactors (SMRs) feature significantly reduced Emergency Planning Zones (EPZs) compared to traditional reactors due to their enhanced safety systems and lower radioactive inventory.

Capital cost per megawatt

Small Modular Reactors (SMRs) typically have a higher capital cost per megawatt compared to traditional reactors due to smaller unit sizes and modular design efficiencies offset by economies of scale in large reactors.

Onsite construction time

SMRs typically reduce onsite construction time by 30-50% compared to traditional reactors due to modular fabrication and simpler designs.

Grid integration flexibility

SMRs offer enhanced grid integration flexibility compared to traditional reactors due to their smaller size, modular design, and ability to rapidly adjust output to match variable energy demands.

SMR vs traditional reactor Infographic

njnir.com

njnir.com