Accident tolerant fuel (ATF) offers enhanced safety features compared to conventional nuclear fuel by improving resistance to high-temperature oxidation and reducing hydrogen generation during severe reactor accidents. These advanced fuels enable extended operation under accident conditions, thereby minimizing the risk of core damage and radioactive release. Implementation of ATF technologies supports the nuclear industry's goals for safer, more resilient reactor designs while maintaining efficient performance.

Table of Comparison

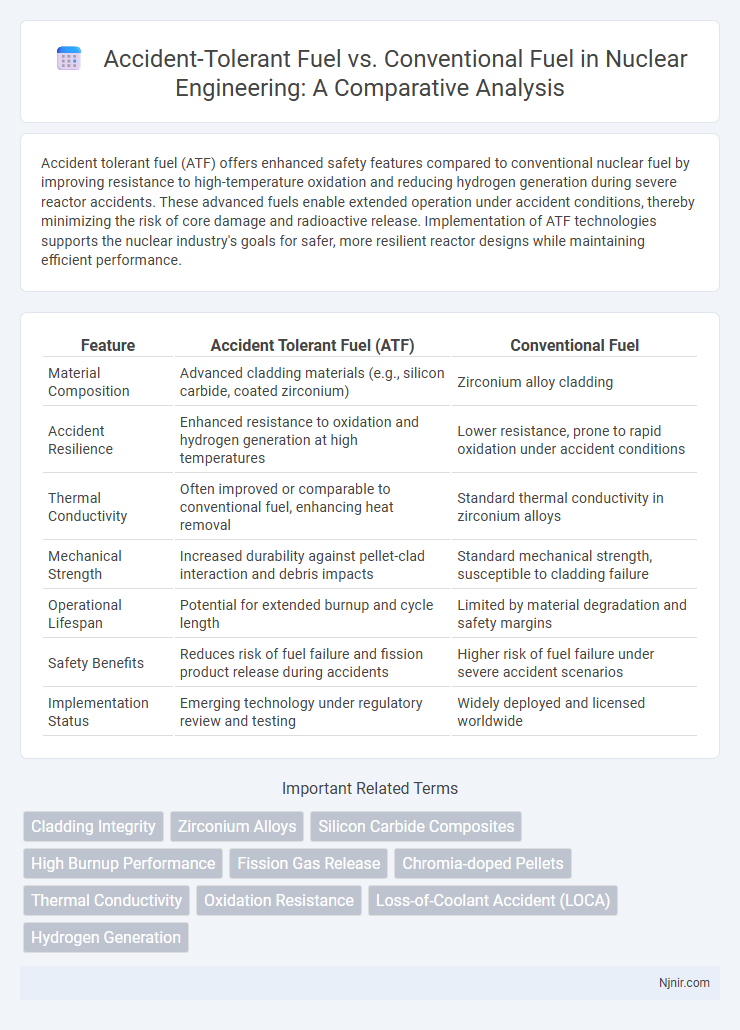

| Feature | Accident Tolerant Fuel (ATF) | Conventional Fuel |

|---|---|---|

| Material Composition | Advanced cladding materials (e.g., silicon carbide, coated zirconium) | Zirconium alloy cladding |

| Accident Resilience | Enhanced resistance to oxidation and hydrogen generation at high temperatures | Lower resistance, prone to rapid oxidation under accident conditions |

| Thermal Conductivity | Often improved or comparable to conventional fuel, enhancing heat removal | Standard thermal conductivity in zirconium alloys |

| Mechanical Strength | Increased durability against pellet-clad interaction and debris impacts | Standard mechanical strength, susceptible to cladding failure |

| Operational Lifespan | Potential for extended burnup and cycle length | Limited by material degradation and safety margins |

| Safety Benefits | Reduces risk of fuel failure and fission product release during accidents | Higher risk of fuel failure under severe accident scenarios |

| Implementation Status | Emerging technology under regulatory review and testing | Widely deployed and licensed worldwide |

Introduction to Nuclear Fuel Types

Accident tolerant fuel (ATF) represents an advanced class of nuclear fuel designed to withstand higher temperatures and reduce hydrogen release compared to conventional uranium dioxide (UO2) fuel used in light water reactors. ATFs incorporate materials such as silicon carbide cladding or uranium silicide pellets, enhancing safety margins during severe accident scenarios by improving thermal conductivity and oxidation resistance. This innovation addresses limitations of traditional fuels, aiming to enhance reactor performance and mitigate risks associated with loss-of-coolant accidents.

Overview of Conventional Nuclear Fuels

Conventional nuclear fuels primarily consist of uranium dioxide (UO2) pellets encased in zirconium alloy cladding, chosen for its low neutron absorption and good mechanical properties. These fuels efficiently sustain fission reactions but face challenges under accident conditions due to zirconium's high reactivity with steam at elevated temperatures, leading to hydrogen generation and increased risk of cladding failure. This limitation drives research into accident tolerant fuels (ATF), designed to improve safety margins by enhancing thermal conductivity, oxidation resistance, and overall resilience during severe events.

What is Accident Tolerant Fuel (ATF)?

Accident Tolerant Fuel (ATF) is a type of nuclear fuel designed to enhance safety by improving resistance to high-temperature accidents and reducing the release of radioactive materials. Unlike conventional uranium dioxide fuel, ATF incorporates advanced materials such as silicon carbide cladding or doped uranium fuel pellets that maintain structural integrity under extreme conditions. This innovation aims to extend the response time during emergency scenarios and mitigate the risks associated with nuclear reactor accidents.

Material Composition: Conventional vs. ATF

Conventional nuclear fuel typically uses uranium dioxide (UO2) pellets encased in zirconium alloy cladding, which is prone to oxidation and degradation under high-temperature accident conditions. Accident tolerant fuels (ATF) incorporate advanced materials such as silicon carbide or chromium-coated zirconium alloys for cladding and utilize doped uranium dioxide or uranium silicide pellets, enhancing thermal conductivity and oxidation resistance. These material innovations in ATF significantly improve safety margins by delaying cladding failure and maintaining fuel integrity during loss-of-coolant accidents.

Safety Performance Comparison

Accident tolerant fuel (ATF) demonstrates enhanced safety performance over conventional fuel by offering improved thermal stability and reduced hydrogen generation during severe nuclear reactor accidents. ATF materials such as advanced cladding and fuel pellets increase resistance to high-temperature oxidation, mitigating the risk of cladding failure and subsequent radioactive release. Experimental data and simulation studies validate ATF's superior performance in maintaining reactor integrity under accident scenarios compared to traditional zirconium-based fuel systems.

Fuel Efficiency and Reactor Operation

Accident tolerant fuel (ATF) offers enhanced fuel efficiency by enabling higher burnup rates and longer fuel cycles compared to conventional uranium dioxide fuel, reducing the frequency of refueling outages. ATF materials, such as silicon carbide cladding or doped uranium dioxide, improve thermal conductivity and oxidation resistance, leading to more stable reactor operation under both normal and transient conditions. These advancements enable reactors to operate at higher power densities with improved safety margins, optimizing overall reactor performance and fuel utilization.

Response to Severe Accident Scenarios

Accident tolerant fuels (ATFs) are designed to enhance safety by maintaining cladding integrity and reducing hydrogen generation during severe accident scenarios compared to conventional uranium dioxide fuel with zirconium alloy cladding. ATFs incorporate materials such as silicon carbide composites and advanced cladding coatings that exhibit higher oxidation resistance and lower heat release under high-temperature conditions. These features significantly improve the reactor core's ability to withstand loss-of-coolant accidents and mitigate the risk of core damage and radioactive release.

Regulatory and Licensing Perspectives

Accident tolerant fuel (ATF) represents a paradigm shift in nuclear safety regulation, with regulatory bodies emphasizing enhanced performance under accident conditions to reduce radiological risks. Licensing frameworks for ATF require extensive safety data and demonstration of behavior under transient scenarios, prompting revisions in codes and standards compared to conventional fuel. Regulatory authorities prioritize comprehensive assessment of cladding integrity, thermal conductivity, and fission product retention to facilitate streamlined approval processes for ATF deployment.

Implementation Challenges and Deployment

Accident tolerant fuel (ATF) faces significant implementation challenges including material qualification, compatibility with existing reactor designs, and extensive regulatory approval processes. Deployment is limited by the need for rigorous testing under operational conditions to ensure safety and performance, often requiring collaborations between industry and research institutions. Despite these hurdles, gradual integration into commercial reactors aims to enhance nuclear safety and extend fuel cycle life.

Future Prospects of Nuclear Fuel Technology

Accident tolerant fuel (ATF) offers enhanced safety features such as improved thermal conductivity and oxidation resistance compared to conventional uranium dioxide fuel, enabling reactors to withstand extreme conditions with reduced risk of severe accidents. Future prospects for nuclear fuel technology emphasize the integration of ATF materials like silicon carbide cladding and uranium silicide fuel pellets to extend reactor operation cycles and enhance fuel efficiency. Advances in ATF development are expected to support next-generation reactors by improving accident resilience, lowering operational costs, and facilitating higher burnup rates.

Cladding Integrity

Accident tolerant fuel enhances cladding integrity by utilizing advanced materials such as silicon carbide or coated zirconium alloys to withstand higher temperatures and reduce oxidation compared to conventional zirconium alloy cladding.

Zirconium Alloys

Accident tolerant fuel utilizing advanced ceramic cladding materials significantly enhances safety compared to conventional zirconium alloy cladding by reducing oxidation rates and hydrogen generation during high-temperature reactor accident scenarios.

Silicon Carbide Composites

Silicon carbide composites in accident tolerant fuels enhance thermal conductivity and oxidation resistance, significantly improving safety and performance over conventional uranium dioxide fuels.

High Burnup Performance

Accident tolerant fuel exhibits superior high burnup performance by maintaining structural integrity and reducing cladding degradation compared to conventional fuel, enhancing reactor safety and efficiency.

Fission Gas Release

Accident tolerant fuel exhibits significantly lower fission gas release compared to conventional fuel, enhancing reactor safety during high-temperature transients.

Chromia-doped Pellets

Chromia-doped pellets in accident tolerant fuel enhance oxidation resistance and structural integrity compared to conventional uranium dioxide pellets, improving safety during nuclear reactor transients.

Thermal Conductivity

Accident tolerant fuel exhibits significantly higher thermal conductivity than conventional fuel, enhancing heat transfer and reducing the risk of overheating during reactor transients.

Oxidation Resistance

Accident tolerant fuel exhibits significantly enhanced oxidation resistance compared to conventional fuel, reducing cladding degradation and improving safety under severe accident conditions.

Loss-of-Coolant Accident (LOCA)

Accident tolerant fuel enhances safety during Loss-of-Coolant Accidents (LOCA) by maintaining structural integrity and reducing hydrogen generation compared to conventional fuel.

Hydrogen Generation

Accident tolerant fuels significantly reduce hydrogen generation during severe nuclear reactor accidents compared to conventional fuels, enhancing reactor safety and minimizing explosion risks.

accident tolerant fuel vs conventional fuel Infographic

njnir.com

njnir.com