High-temperature gas-cooled reactors (HTGRs) utilize helium as a coolant, offering excellent thermal conductivity and high outlet temperatures ideal for efficient electricity generation and hydrogen production. Supercritical water reactors (SCWRs) operate at higher pressures and temperatures with water as a coolant, enabling improved thermal efficiency and simplified design by eliminating the need for steam generators. While HTGRs emphasize inherent safety and fuel integrity through TRISO fuel particles, SCWRs leverage familiar water-based technology to achieve higher power density and enhanced economic competitiveness.

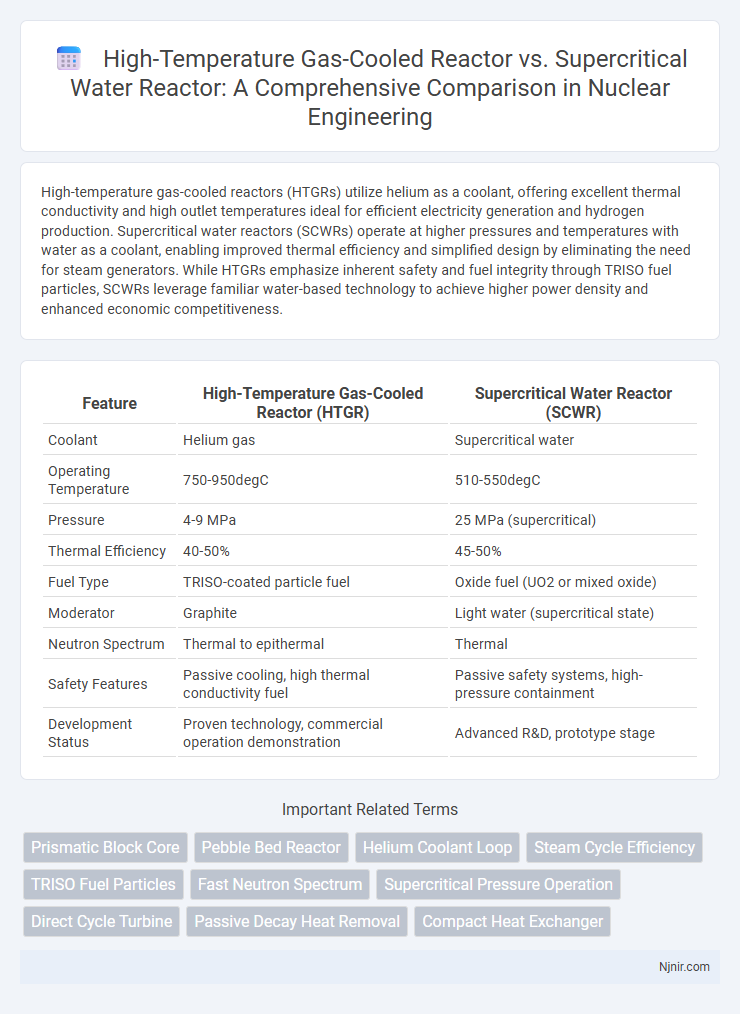

Table of Comparison

| Feature | High-Temperature Gas-Cooled Reactor (HTGR) | Supercritical Water Reactor (SCWR) |

|---|---|---|

| Coolant | Helium gas | Supercritical water |

| Operating Temperature | 750-950degC | 510-550degC |

| Pressure | 4-9 MPa | 25 MPa (supercritical) |

| Thermal Efficiency | 40-50% | 45-50% |

| Fuel Type | TRISO-coated particle fuel | Oxide fuel (UO2 or mixed oxide) |

| Moderator | Graphite | Light water (supercritical state) |

| Neutron Spectrum | Thermal to epithermal | Thermal |

| Safety Features | Passive cooling, high thermal conductivity fuel | Passive safety systems, high-pressure containment |

| Development Status | Proven technology, commercial operation demonstration | Advanced R&D, prototype stage |

Introduction to Advanced Nuclear Reactor Designs

High-temperature gas-cooled reactors (HTGRs) utilize helium coolant and graphite moderators to achieve outlet temperatures above 750degC, enhancing thermal efficiency and hydrogen production capabilities. Supercritical water reactors (SCWRs) operate with water at supercritical pressures around 25 MPa and temperatures exceeding 500degC, enabling high thermal efficiency through a simplified direct cycle. Both designs represent advanced nuclear reactor technologies aimed at improving safety, efficiency, and versatility in next-generation power generation systems.

Overview of High-Temperature Gas-Cooled Reactors (HTGR)

High-Temperature Gas-Cooled Reactors (HTGR) utilize helium as a coolant and graphite as a moderator, enabling operation at core outlet temperatures up to 750-950degC, which enhances thermal efficiency and supports hydrogen production. The reactor design features ceramic-coated fuel particles for improved fission product retention and inherent safety characteristics under loss-of-coolant scenarios. Compared to Supercritical Water Reactors (SCWR) that operate at supercritical pressures with water as coolant, HTGRs offer distinct advantages in high-temperature process heat applications and passive safety systems.

Overview of Supercritical Water Reactors (SCWR)

Supercritical Water Reactors (SCWR) operate at pressures above 22.1 MPa and temperatures exceeding 500degC, allowing water to act as a single-phase coolant with superior heat transfer properties. Compared to High-Temperature Gas-Cooled Reactors (HTGR), SCWRs offer higher thermal efficiency, potentially reaching 45% or more, due to the supercritical steam cycle. The SCWR design simplifies the coolant system by eliminating phase change, but poses significant challenges in materials corrosion and reactor core cooling stability under supercritical conditions.

Core Design and Fuel Characteristics

The high-temperature gas-cooled reactor (HTGR) features a core design with graphite moderator and helium coolant enabling high outlet temperatures up to 750degC, while utilizing TRISO fuel particles embedded in graphite pebbles or compacts for enhanced stability and fission product retention. In contrast, the supercritical water reactor (SCWR) incorporates a light-water coolant operated above the thermodynamic critical point of water at about 374degC and 22 MPa, with a core design emphasizing compact fuel assemblies using conventional uranium dioxide fuel to withstand higher thermal and mechanical stresses. Both reactor types prioritize improved thermal efficiency and safety, but HTGR's ceramic-coated fuel particles offer superior resistance to high temperatures compared to SCWR's traditional fuel materials.

Coolant Properties and Heat Transfer Mechanisms

High-temperature gas-cooled reactors (HTGRs) use helium as a coolant, benefiting from its excellent thermal conductivity, chemical inertness, and high specific heat capacity, which enables efficient heat transfer at temperatures up to 750-950degC. In contrast, supercritical water reactors (SCWRs) utilize supercritical water above 374degC and 22.1 MPa, offering superior heat transfer properties due to the fluid's single-phase characteristics and high density, dramatically improving thermal efficiency. The gaseous helium in HTGRs provides low neutron moderation and high heat transfer stability with convective heat transfer mechanisms, whereas SCWRs rely on convective and turbulent heat transfer in supercritical fluid conditions, leading to complex heat transfer dynamics that enhance reactor compactness and efficiency.

Thermal Efficiency and Power Output Comparison

High-temperature gas-cooled reactors (HTGRs) achieve thermal efficiencies around 45%, leveraging helium coolant's high thermal conductivity and operating temperatures up to 750degC. Supercritical water reactors (SCWRs) can reach thermal efficiencies exceeding 45-50% due to their supercritical coolant state and higher operating temperatures near 600degC to 625degC. Despite HTGRs having slightly lower power density, their high outlet temperatures enable effective process heat applications, whereas SCWRs offer higher power output through compact core design and direct cycle operation.

Safety Features and Passive Systems

High-temperature gas-cooled reactors (HTGRs) feature robust ceramic fuel and helium coolant, providing inherent safety through high thermal conductivity and low chemical reactivity, which significantly reduce meltdown risk. Supercritical water reactors (SCWRs) employ water at supercritical pressures, enhancing heat transfer but requiring advanced passive safety systems like passive core cooling and emergency depressurization to mitigate pressure-related accidents. Both reactor types integrate passive safety systems designed to operate without active controls or external power, with HTGRs relying on natural convection for decay heat removal and SCWRs utilizing gravity-driven cooling loops for emergency core cooling.

Materials and Structural Challenges

High-temperature gas-cooled reactors (HTGRs) use graphite as a core structural material due to its high-temperature stability and neutron moderation, but face challenges with irradiation-induced dimensional changes and oxidation. Supercritical water reactors (SCWRs) operate at temperatures above 374degC and pressures of 22.1 MPa, requiring advanced corrosion-resistant materials like austenitic stainless steels or nickel-based alloys to withstand aggressive supercritical water environments. Both reactor types demand innovative materials solutions to address thermal creep, corrosion, and radiation damage for long-term structural integrity.

Economic and Deployment Considerations

High-temperature gas-cooled reactors (HTGRs) offer economic advantages through their fuel efficiency and modular construction, enabling incremental capacity additions and reduced upfront capital costs. Supercritical water reactors (SCWRs) promise higher thermal efficiencies, which can translate into lower operation costs, but their deployment requires overcoming significant material and technological challenges, potentially increasing initial expenses. HTGRs currently benefit from more advanced licensing and demonstration projects, whereas SCWRs remain in earlier development stages, impacting their near-term commercial viability and deployment timelines.

Future Prospects and Research Directions

High-temperature gas-cooled reactors (HTGRs) demonstrate promising future prospects due to their superior safety features and high thermal efficiency, enabling hydrogen production and process heat applications. Supercritical water reactors (SCWRs) are a key focus in advanced nuclear research, aiming to achieve higher thermal efficiencies above 45% by operating at supercritical pressures and temperatures. Current research directions for HTGRs emphasize material improvements and fuel cycle optimization, while SCWR development prioritizes corrosion-resistant materials and coolant chemistry to ensure long-term operational stability.

Prismatic Block Core

The Prismatic Block Core design in high-temperature gas-cooled reactors offers enhanced fuel stability and efficient heat transfer compared to the complex cooling requirements of supercritical water reactors.

Pebble Bed Reactor

The Pebble Bed Reactor, a type of high-temperature gas-cooled reactor, offers enhanced safety through passive cooling and continuous fuel circulation compared to the higher pressure and complex materials challenges in supercritical water reactors.

Helium Coolant Loop

The high-temperature gas-cooled reactor utilizes a helium coolant loop known for its excellent thermal conductivity and inertness, enabling efficient heat transfer and enhanced safety compared to the supercritical water reactor's water-based coolant system.

Steam Cycle Efficiency

High-temperature gas-cooled reactors achieve higher steam cycle efficiency, reaching up to 47%, compared to supercritical water reactors, which typically exhibit efficiencies around 45% due to their operational supercritical steam conditions.

TRISO Fuel Particles

High-temperature gas-cooled reactors utilize TRISO fuel particles for enhanced safety and fuel integrity under extreme temperatures, whereas supercritical water reactors do not typically employ TRISO fuel, relying instead on conventional fuel types optimized for supercritical water conditions.

Fast Neutron Spectrum

High-temperature gas-cooled reactors utilize a thermal neutron spectrum for efficient fuel utilization, while supercritical water reactors typically operate with a fast neutron spectrum to enhance neutron economy and fuel burnup.

Supercritical Pressure Operation

Supercritical water reactors operate at pressures above 22.1 MPa to achieve a single-phase fluid state for improved thermal efficiency, while high-temperature gas-cooled reactors utilize helium coolant at lower pressures around 7 MPa to maintain graphite-moderated reactor core stability.

Direct Cycle Turbine

The high-temperature gas-cooled reactor (HTGR) employs a direct cycle turbine using helium as a coolant for efficient power conversion at high thermal efficiencies, whereas the supercritical water reactor (SCWR) utilizes supercritical water in its direct cycle turbine, enabling higher thermal efficiency through simplified coolant and steam cycle integration.

Passive Decay Heat Removal

High-temperature gas-cooled reactors utilize inert helium gas for efficient passive decay heat removal through natural convection and conduction, while supercritical water reactors rely on supercritical steam properties to enhance passive heat dissipation but face challenges due to higher pressure and temperature conditions.

Compact Heat Exchanger

High-temperature gas-cooled reactors utilize compact heat exchangers made from corrosion-resistant materials to efficiently transfer heat at temperatures exceeding 750degC, whereas supercritical water reactors require compact heat exchangers designed to withstand high pressures above 22 MPa and temperatures around 550degC, demanding advanced materials and enhanced thermal-hydraulic performance.

high-temperature gas-cooled reactor vs supercritical water reactor Infographic

njnir.com

njnir.com