On-site reprocessing allows nuclear facilities to handle spent fuel directly, reducing transportation risks and enhancing security by limiting radioactive material movement. Centralized reprocessing benefits from economies of scale, specialized expertise, and advanced technology, resulting in higher recovery efficiencies and improved waste management. Both approaches impact operational costs, regulatory complexity, and proliferation concerns, requiring careful evaluation to balance safety, economics, and environmental sustainability.

Table of Comparison

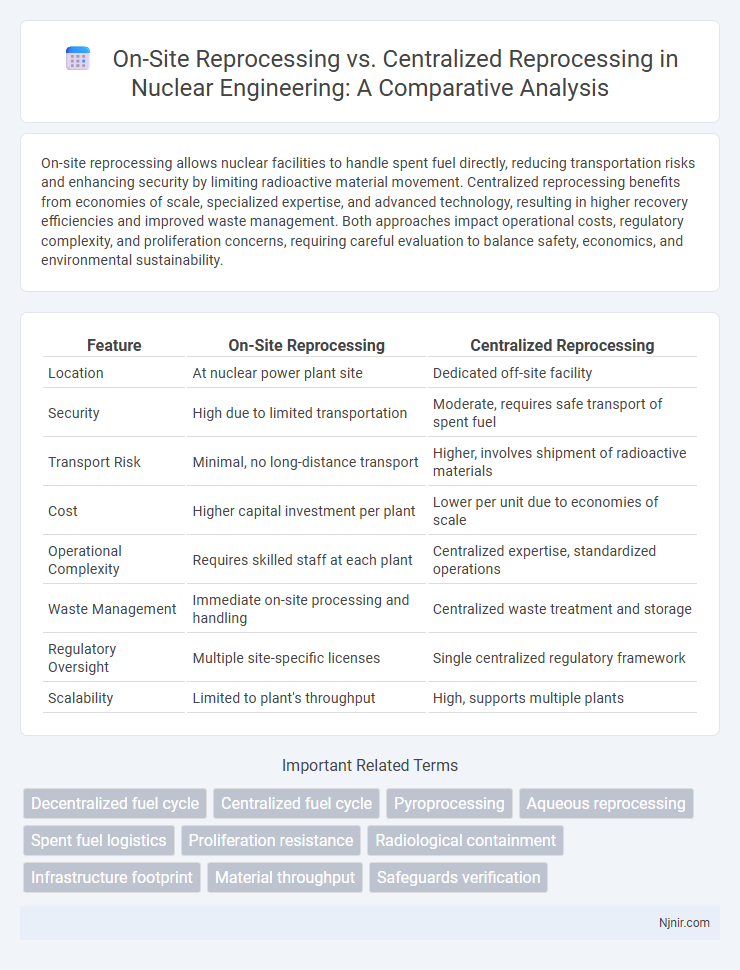

| Feature | On-Site Reprocessing | Centralized Reprocessing |

|---|---|---|

| Location | At nuclear power plant site | Dedicated off-site facility |

| Security | High due to limited transportation | Moderate, requires safe transport of spent fuel |

| Transport Risk | Minimal, no long-distance transport | Higher, involves shipment of radioactive materials |

| Cost | Higher capital investment per plant | Lower per unit due to economies of scale |

| Operational Complexity | Requires skilled staff at each plant | Centralized expertise, standardized operations |

| Waste Management | Immediate on-site processing and handling | Centralized waste treatment and storage |

| Regulatory Oversight | Multiple site-specific licenses | Single centralized regulatory framework |

| Scalability | Limited to plant's throughput | High, supports multiple plants |

Introduction to Nuclear Fuel Reprocessing

Nuclear fuel reprocessing involves chemically separating usable fissile materials from spent nuclear fuel to reduce waste and recycle valuable isotopes like plutonium and uranium. On-site reprocessing occurs directly at the nuclear power plant, offering reduced transportation risks and quicker turnaround, while centralized reprocessing is conducted at specialized facilities designed for higher efficiency and capacity. Both methods aim to optimize fuel utilization and minimize nuclear waste, but centralized reprocessing benefits from advanced technology and economies of scale.

Overview: On-Site vs Centralized Reprocessing

On-site reprocessing involves sterilizing medical instruments within the healthcare facility, ensuring immediate availability and reducing turnaround times. Centralized reprocessing consolidates sterilization in a dedicated off-site facility, promoting stringent quality control and cost efficiency through scale. Choosing between on-site and centralized reprocessing depends on factors like facility size, instrument volume, and regulatory requirements.

Nuclear Security and Safeguards Considerations

On-site reprocessing reduces the risk of nuclear proliferation by limiting the transport of fissile materials, enhancing control over nuclear materials and improving real-time monitoring for safeguards compliance. Centralized reprocessing facilities benefit from advanced security infrastructure and specialized personnel, but they increase vulnerabilities during transportation and require robust international oversight to prevent diversion. Effective nuclear security frameworks must balance the risks of material movement with the benefits of centralized expertise and technology in safeguarding nuclear materials.

Economic Analysis and Cost Implications

On-site reprocessing of medical devices reduces transportation costs and turnaround times, leading to lower overall operational expenses compared to centralized reprocessing facilities. Centralized reprocessing benefits from economies of scale, such as bulk purchasing of supplies and advanced sterilization technologies, which can decrease per-unit costs but may incur higher logistics and staffing overhead. Economic analyses consistently show that choosing between on-site and centralized options depends on facility volume, with on-site reprocessing being more cost-effective for smaller institutions and centralized reprocessing yielding savings in high-volume hospital networks.

Infrastructure Requirements and Scalability

On-site reprocessing demands dedicated space, specialized equipment, and trained personnel within each healthcare facility, limiting scalability due to high initial setup costs and maintenance needs. Centralized reprocessing consolidates resources in a single, high-capacity facility, optimizing infrastructure utilization and enabling easier scalability to handle increased instrument volumes across multiple locations. Streamlined workflows and advanced automation in centralized units improve throughput and reduce redundancy, making it more cost-effective for large healthcare networks.

Environmental Impact Assessment

On-site reprocessing of medical instruments significantly reduces carbon emissions by minimizing transportation and packaging waste compared to centralized reprocessing facilities. Life Cycle Assessments (LCA) indicate that on-site reprocessing lowers water and energy consumption due to localized sterilization processes, contributing to a smaller environmental footprint. Centralized reprocessing, while efficient in scale, often incurs higher greenhouse gas emissions from logistics and requires increased use of disposable materials to maintain sterility during transit.

Transportation Risks and Logistics

On-site reprocessing minimizes transportation risks by eliminating the need to move sterile instruments between facilities, reducing exposure to contamination and damage during transit. Centralized reprocessing requires meticulous logistics planning to ensure timely, secure transport, which can introduce delays and increase the risk of lost or compromised sterile items. Effective tracking systems and specialized packaging are essential to mitigate these transportation risks in centralized reprocessing models.

Waste Management and Byproduct Handling

On-site reprocessing enables immediate waste segregation and treatment, minimizing contamination risks and reducing the volume of hazardous byproducts through localized handling protocols. Centralized reprocessing facilities implement standardized waste management systems that enhance recovery rates of valuable materials while ensuring compliance with stringent environmental regulations. Efficient byproduct handling in centralized plants supports better resource recovery, lowering environmental impact compared to dispersed on-site disposal methods.

Flexibility and Operational Efficiency

On-site reprocessing offers greater flexibility by enabling immediate sterilization and turnaround of medical instruments, reducing dependency on external schedules and transportation delays. Centralized reprocessing enhances operational efficiency through standardized processes, economies of scale, and specialized expertise, leading to consistent quality and reduced overall costs. Healthcare facilities must balance the need for rapid instrument availability with the benefits of streamlined workflows when choosing between these models.

Policy, Regulation, and Public Perception

On-site reprocessing faces stricter policy scrutiny due to concerns over infection control and device integrity, while centralized reprocessing benefits from standardized regulatory frameworks and accreditation by agencies such as the FDA and Joint Commission. Regulations mandate rigorous validation and monitoring protocols, with centralized facilities often perceived as more reliable and compliant, enhancing public trust. Public perception tends to favor centralized reprocessing for its perceived higher safety standards, although transparent communication can improve acceptance of on-site practices.

Decentralized fuel cycle

Decentralized fuel cycles employ on-site reprocessing to reduce transportation risks and enhance security by enabling localized recycling of nuclear fuel.

Centralized fuel cycle

Centralized fuel cycle facilities enhance nuclear fuel management efficiency and safety by concentrating reprocessing operations, reducing on-site risks and enabling advanced waste treatment technologies.

Pyroprocessing

Pyroprocessing demonstrates enhanced efficiency and contamination control in on-site reprocessing compared to centralized reprocessing by enabling immediate treatment of spent nuclear fuel at the reactor site.

Aqueous reprocessing

Aqueous reprocessing is more efficiently managed through centralized facilities due to enhanced radiological safety, superior contaminant control, and optimized resource utilization compared to on-site reprocessing.

Spent fuel logistics

On-site reprocessing reduces spent fuel transportation risks and costs by minimizing logistics complexity compared to centralized reprocessing facilities.

Proliferation resistance

Centralized reprocessing enhances proliferation resistance by consolidating nuclear material handling in secured facilities with stringent monitoring, reducing risks associated with dispersed on-site reprocessing operations.

Radiological containment

On-site reprocessing enhances radiological containment by minimizing the transport of radioactive materials compared to centralized reprocessing facilities.

Infrastructure footprint

On-site reprocessing requires a smaller infrastructure footprint by utilizing existing facility resources, whereas centralized reprocessing demands larger specialized facilities and dedicated logistics for sterilization and distribution.

Material throughput

On-site reprocessing offers faster material throughput by eliminating transportation delays, whereas centralized reprocessing benefits from higher scalability but may experience slower overall material flow due to logistic constraints.

Safeguards verification

On-site reprocessing enables more immediate safeguards verification through direct monitoring and reduced transport risks, while centralized reprocessing offers standardized control but increases complexity in safeguarding due to extended material handling and geographic separation.

on-site reprocessing vs centralized reprocessing Infographic

njnir.com

njnir.com