Molten salt reactors use liquid fuel dissolved in molten salt, offering improved thermal conductivity and inherent safety features compared to solid fuel reactors, which rely on fixed fuel rods. The fluid nature of molten salt allows continuous fuel reprocessing and reduces the risk of meltdown, enhancing efficiency and waste management. In contrast, solid fuel reactors face challenges with fuel swelling and limited operational flexibility, making molten salt reactors a promising alternative for next-generation nuclear power.

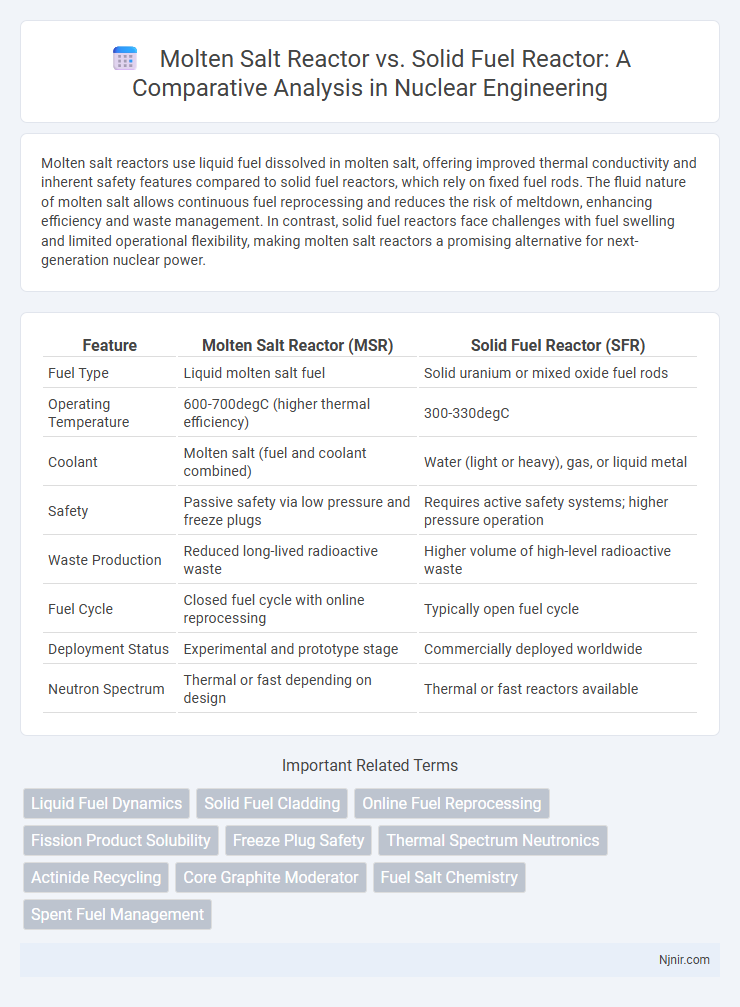

Table of Comparison

| Feature | Molten Salt Reactor (MSR) | Solid Fuel Reactor (SFR) |

|---|---|---|

| Fuel Type | Liquid molten salt fuel | Solid uranium or mixed oxide fuel rods |

| Operating Temperature | 600-700degC (higher thermal efficiency) | 300-330degC |

| Coolant | Molten salt (fuel and coolant combined) | Water (light or heavy), gas, or liquid metal |

| Safety | Passive safety via low pressure and freeze plugs | Requires active safety systems; higher pressure operation |

| Waste Production | Reduced long-lived radioactive waste | Higher volume of high-level radioactive waste |

| Fuel Cycle | Closed fuel cycle with online reprocessing | Typically open fuel cycle |

| Deployment Status | Experimental and prototype stage | Commercially deployed worldwide |

| Neutron Spectrum | Thermal or fast depending on design | Thermal or fast reactors available |

Introduction to Nuclear Reactor Types

Molten salt reactors (MSRs) use liquid fuel mixtures of molten salts that enable continuous fuel processing, offering improved safety and efficiency compared to traditional solid fuel reactors that use fixed fuel rods. Solid fuel reactors, such as pressurized water reactors (PWRs) and boiling water reactors (BWRs), rely on ceramic uranium oxide pellets encapsulated in metal cladding, which limits real-time reactivity control and generates greater long-lived radioactive waste. MSRs provide operational advantages through flexible fuel composition and inherent safety features, positioning them as a promising next-generation nuclear technology.

Overview of Molten Salt Reactors

Molten salt reactors (MSRs) utilize liquid fuel dissolved in molten salt, enabling higher operating temperatures and improved thermal efficiency compared to solid fuel reactors. Their design allows continuous fuel processing and waste removal, reducing long-lived radioactive waste and enhancing safety by operating at low pressure. MSRs demonstrate potential for flexible fuel cycles and enhanced proliferation resistance, distinguishing them from traditional solid fuel reactors that rely on fixed, solid uranium or mixed oxide fuel assemblies.

Overview of Solid Fuel Reactors

Solid fuel reactors use uranium or plutonium fuel pellets encased in metal cladding arranged in fixed fuel rods within the reactor core, providing a stable and well-understood matrix for nuclear fission. These reactors rely on solid-state fuel, which simplifies handling and containment but limits temperature operation to lower ranges compared to molten salt reactors. Solid fuel reactors have a long history of commercial use, including pressurized water reactors (PWRs) and boiling water reactors (BWRs), with extensive infrastructure, regulatory frameworks, and fuel fabrication facilities supporting their deployment.

Fuel Design and Fuel Cycle Differences

Molten salt reactors use liquid fuel mixtures where fissile materials dissolve directly in the molten salt, allowing continuous fuel processing and on-site reprocessing, which reduces waste and improves resource utilization. Solid fuel reactors utilize solid fuel rods or pellets, requiring periodic shutdowns for refueling and off-site fuel handling, leading to a batch-wise fuel cycle with limited online reprocessing. The liquid fuel design of molten salt reactors enables higher burnup rates and better thermal efficiency compared to the fixed geometry and limited burnup of solid fuel assemblies.

Coolant System Comparison

Molten salt reactors use liquid salt mixtures as both fuel solvent and coolant, offering high thermal capacity, low pressure operation, and excellent heat transfer efficiency compared to conventional solid fuel reactors that rely on water or gas coolants. This liquid coolant enables continuous fuel reprocessing and reduces the risk of meltdown due to its chemical stability and high boiling point. Solid fuel reactors require pressurized coolant systems prone to high-pressure accidents, whereas molten salt reactors inherently improve safety through low-pressure, high-temperature coolant circulation.

Safety Features and Risk Profiles

Molten salt reactors (MSRs) offer enhanced safety features due to their low operating pressure and inherent passive cooling capabilities, reducing risks of high-pressure explosions compared to solid fuel reactors. The liquid fuel in MSRs allows for continuous removal of fission products and heat, minimizing the risk of fuel meltdown and facilitating immediate response to temperature fluctuations. Solid fuel reactors, by contrast, rely on robust containment structures and active cooling systems to manage higher risks of fuel rod failure and radioactive release during overheating or loss-of-coolant accidents.

Operational Efficiency and Flexibility

Molten salt reactors (MSRs) offer superior operational efficiency by enabling continuous fuel reprocessing and higher thermal efficiency due to their liquid fuel form, which allows for constant refueling and reduced downtime. Solid fuel reactors operate in batch cycles requiring periodic shutdowns for refueling, limiting their flexibility and increasing maintenance intervals. The intrinsic flexibility of MSRs supports load-following capabilities and diverse fuel types, enhancing adaptability in power generation compared to the more rigid operational schedules of solid fuel reactors.

Waste Generation and Management

Molten salt reactors (MSRs) produce significantly less long-lived radioactive waste compared to solid fuel reactors due to continuous fuel reprocessing and the ability to consume existing nuclear waste as fuel. The liquid fuel in MSRs allows for on-site separation and recycling of actinides, reducing the volume and toxicity of high-level waste requiring storage. In contrast, solid fuel reactors generate higher quantities of spent fuel assemblies that demand extensive long-term management and repository space due to their fixed composition and slower decay rates.

Economic Considerations

Molten salt reactors (MSRs) offer economic advantages through lower fuel costs and enhanced fuel efficiency compared to traditional solid fuel reactors, as their liquid fuel allows continuous reprocessing and reduces waste management expenses. MSRs also benefit from simpler reactor designs and reduced onsite refueling downtime, leading to higher capacity factors and operational savings. In contrast, solid fuel reactors incur higher fabrication and handling costs due to the complexity of solid fuel assemblies and require longer shutdown periods for refueling, increasing operational expenses.

Future Prospects and Development Trends

Molten salt reactors (MSRs) offer significant future prospects due to their inherent safety features, high thermal efficiency, and ability to utilize thorium fuel cycles, positioning them as a promising technology for sustainable nuclear energy. Ongoing development trends emphasize advanced materials to withstand corrosive salts, improved online refueling capabilities, and integration with renewable energy systems. In contrast, solid fuel reactors continue to evolve with enhancements in fuel fabrication, accident-tolerant fuels, and small modular reactor designs, but face challenges in waste management and thermal constraints compared to MSRs.

Liquid Fuel Dynamics

Molten salt reactors utilize liquid fuel that enables continuous reprocessing and enhanced heat transfer compared to the static solid fuel found in traditional solid fuel reactors, improving safety and fuel efficiency.

Solid Fuel Cladding

Solid fuel reactor cladding primarily relies on zirconium alloys for high-temperature strength and corrosion resistance, while molten salt reactors eliminate traditional cladding by dissolving fuel in liquid salts, reducing structural material constraints and enhancing safety.

Online Fuel Reprocessing

Molten salt reactors enable continuous online fuel reprocessing by chemically separating fission products from the liquid fuel salt, whereas solid fuel reactors require periodic shutdowns for offline reprocessing and fuel replacement.

Fission Product Solubility

Molten salt reactors exhibit superior fission product solubility compared to solid fuel reactors, enabling enhanced removal and containment of radioactive isotopes during operation.

Freeze Plug Safety

Molten salt reactors enhance Freeze Plug Safety by automatically draining fuel into passive cooling tanks upon failure, unlike solid fuel reactors that rely on active safety systems to prevent overheating.

Thermal Spectrum Neutronics

Molten salt reactors exhibit superior thermal spectrum neutronics compared to solid fuel reactors by enabling continuous fuel circulation, enhanced neutron economy, and improved temperature coefficients that optimize reactivity control and fuel utilization.

Actinide Recycling

Molten salt reactors enable more efficient actinide recycling by continuously dissolving and processing fuel, reducing long-lived nuclear waste compared to traditional solid fuel reactors.

Core Graphite Moderator

Molten salt reactors utilize core graphite moderators with higher neutron economy and improved thermal conductivity compared to solid fuel reactors, enhancing reactor efficiency and safety.

Fuel Salt Chemistry

Fuel salt chemistry in molten salt reactors enables continuous online reprocessing and corrosion resistance, contrasting with the fixed composition and limited adaptability of solid fuel in traditional reactors.

Spent Fuel Management

Molten salt reactors generate less long-lived radioactive waste and enable on-site reprocessing of spent fuel, significantly reducing the complexity and volume of spent fuel management compared to solid fuel reactors.

molten salt reactor vs solid fuel reactor Infographic

njnir.com

njnir.com