MOX fuel, composed of a blend of plutonium and uranium oxides, offers enhanced fuel efficiency and better utilization of plutonium compared to traditional uranium dioxide fuel. It enables the recycling of plutonium from spent fuel, reducing nuclear waste and reliance on natural uranium resources while maintaining comparable reactor performance. The implementation of MOX fuel requires careful handling and modifications in reactor operation due to its higher radiotoxicity and different neutron spectrum characteristics.

Table of Comparison

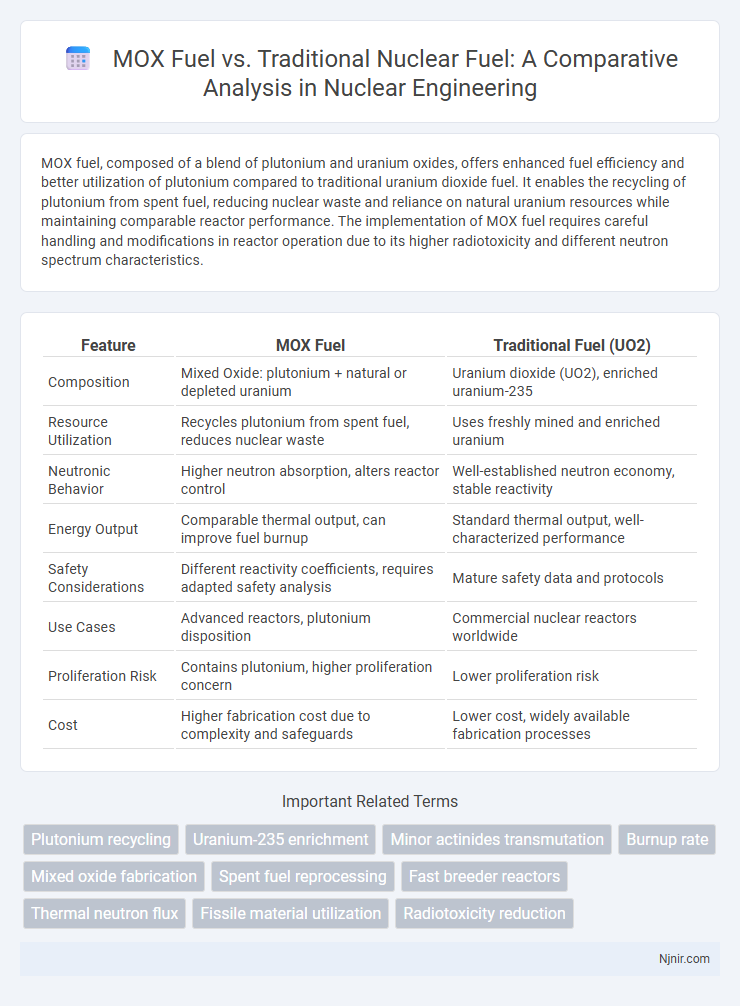

| Feature | MOX Fuel | Traditional Fuel (UO2) |

|---|---|---|

| Composition | Mixed Oxide: plutonium + natural or depleted uranium | Uranium dioxide (UO2), enriched uranium-235 |

| Resource Utilization | Recycles plutonium from spent fuel, reduces nuclear waste | Uses freshly mined and enriched uranium |

| Neutronic Behavior | Higher neutron absorption, alters reactor control | Well-established neutron economy, stable reactivity |

| Energy Output | Comparable thermal output, can improve fuel burnup | Standard thermal output, well-characterized performance |

| Safety Considerations | Different reactivity coefficients, requires adapted safety analysis | Mature safety data and protocols |

| Use Cases | Advanced reactors, plutonium disposition | Commercial nuclear reactors worldwide |

| Proliferation Risk | Contains plutonium, higher proliferation concern | Lower proliferation risk |

| Cost | Higher fabrication cost due to complexity and safeguards | Lower cost, widely available fabrication processes |

Introduction to MOX Fuel and Traditional Nuclear Fuel

MOX fuel, or Mixed Oxide fuel, combines plutonium and uranium oxides to utilize recycled nuclear materials, increasing fuel efficiency and reducing nuclear waste. Traditional nuclear fuel primarily consists of low-enriched uranium, typically uranium-235, which undergoes fission to generate energy in conventional reactors. MOX fuel offers sustainability advantages by recycling plutonium from spent fuel, whereas traditional fuel relies solely on freshly enriched uranium.

Composition and Fabrication Processes

MOX fuel, or Mixed Oxide fuel, is composed primarily of a blend of plutonium dioxide (PuO2) and uranium dioxide (UO2), contrasting traditional nuclear fuel which typically consists of purely enriched UO2. The fabrication process for MOX fuel involves handling recycled plutonium from spent nuclear fuel, requiring specialized glovebox facilities to ensure criticality safety and radiological protection, whereas traditional fuel fabrication primarily focuses on uranium enrichment and pelletizing under less stringent radiological constraints. MOX fuel fabrication also demands precise control of material ratios and sintering conditions to maintain fuel integrity and performance comparable to conventional uranium fuel used in light water reactors.

Nuclear Reactions and Energy Yield

MOX fuel, composed of a mixture of plutonium and uranium oxides, undergoes nuclear fission reactions where plutonium-239 and uranium-235 isotopes release energy by splitting atomic nuclei, resulting in a higher neutron flux compared to traditional uranium fuel. The presence of plutonium in MOX allows for a more efficient utilization of fissile material, increasing the overall energy yield per unit of fuel and reducing nuclear waste. Traditional uranium oxide fuel primarily relies on uranium-235 fission, producing steady but lower energy output and generating more long-lived radioactive waste.

Resource Utilization and Sustainability

MOX fuel, composed of mixed oxides of plutonium and uranium, enhances resource utilization by recycling spent nuclear fuel, reducing the need for fresh uranium extraction compared to traditional uranium-only fuel. This recycling process decreases nuclear waste volume and extends the life cycle of nuclear fuel resources, supporting sustainability goals in nuclear energy production. Consequently, MOX fuel presents a more efficient and environmentally responsible alternative to conventional nuclear fuels.

Safety Considerations and Operational Differences

MOX fuel, composed of mixed oxides of plutonium and uranium, presents distinct safety considerations compared to traditional uranium fuel due to its higher radioactivity and heat generation, requiring enhanced handling protocols and shielding measures. Operational differences include the need for specialized reactor designs or modifications to accommodate MOX fuel's different neutron spectrum and thermal properties, affecting reactor control and fuel management strategies. Despite these challenges, MOX fuel offers the advantage of recycling plutonium from spent nuclear fuel, contributing to waste reduction and resource efficiency.

Waste Management and Spent Fuel Handling

MOX fuel, composed of mixed oxides like plutonium and uranium, reduces the volume and radiotoxicity of nuclear waste compared to traditional uranium oxide fuel by recycling plutonium from spent fuel, thereby enhancing waste management efficiency. Spent MOX fuel requires specialized handling due to its higher radioactivity and heat output, necessitating advanced cooling systems and shielded storage facilities to ensure safe long-term containment. Using MOX fuel also decreases the accumulation of high-level waste by reusing fissile materials, contributing to a more sustainable nuclear fuel cycle and reducing the burden on geological repositories.

Proliferation Risks and Security Concerns

MOX fuel, composed of mixed plutonium and uranium oxides, poses higher proliferation risks compared to traditional low-enriched uranium fuel due to the presence of weapons-grade plutonium that can be diverted for nuclear weapons. The security concerns around MOX fuel include the potential for terrorist acquisition and enhanced safeguards required to prevent illicit use during transportation, storage, and reprocessing. Traditional uranium fuel typically involves lower enrichment levels, resulting in less attractive material for weaponization and reduced security burdens.

Economic Analysis and Cost Efficiency

MOX fuel, containing a blend of plutonium and uranium oxides, offers significant economic advantages over traditional uranium fuel by reducing the need for natural uranium mining and lowering waste management expenses. Cost efficiency is enhanced through the recycling of plutonium from spent nuclear fuel, which extends fuel supply and mitigates disposal costs associated with high-level radioactive waste. While upfront fabrication costs of MOX fuel are higher due to complex processing, long-term savings arise from improved resource utilization and decreased reliance on fresh uranium ore.

Global Deployment and Regulatory Frameworks

MOX fuel, composed of mixed oxide uranium and plutonium, has seen growing global deployment primarily in countries like Japan, France, and Russia, which leverage its ability to recycle plutonium from spent nuclear fuel and reduce radioactive waste. Regulatory frameworks for MOX fuel are stringent, involving coordinated international standards from bodies such as the International Atomic Energy Agency (IAEA) to ensure safe handling, transport, and use within nuclear reactors. In contrast, traditional uranium fuel has a broader, more established regulatory base worldwide, with extensive infrastructure supporting its extraction, enrichment, and usage, resulting in widespread adoption and easier international trade.

Future Trends and Technological Innovations

MOX fuel, composed of recycled plutonium and uranium oxides, offers a sustainable alternative to traditional uranium fuel by enabling the reuse of spent nuclear material, reducing nuclear waste and enhancing resource efficiency. Future trends emphasize advanced fabrication techniques such as microstructured fuel pellets and improved cladding materials to increase thermal conductivity and safety margins. Technological innovations include integrating MOX fuel into fast breeder reactors and small modular reactors, promoting proliferation resistance and enabling more flexible, efficient nuclear power generation.

Plutonium recycling

MOX fuel effectively recycles plutonium extracted from spent nuclear fuel, reducing radioactive waste and enhancing resource utilization compared to traditional uranium-based fuel.

Uranium-235 enrichment

MOX fuel contains a mixture of plutonium and natural or depleted uranium with lower Uranium-235 enrichment compared to traditional enriched uranium fuel, which typically has 3-5% Uranium-235 concentration for effective nuclear fission.

Minor actinides transmutation

MOX fuel significantly enhances minor actinides transmutation efficiency compared to traditional fuel, reducing long-lived radioactive waste and improving nuclear fuel sustainability.

Burnup rate

MOX fuel achieves a higher burnup rate of up to 55 GWd/t compared to traditional uranium fuel's average of 45 GWd/t, enhancing fuel efficiency and reducing nuclear waste.

Mixed oxide fabrication

Mixed oxide (MOX) fuel fabrication, which blends plutonium oxide with uranium oxide, offers a sustainable alternative to traditional uranium fuel by recycling plutonium from spent nuclear fuel and reducing nuclear waste.

Spent fuel reprocessing

MOX fuel enables efficient reuse of plutonium from spent nuclear fuel through advanced reprocessing techniques, significantly reducing radioactive waste compared to traditional uranium fuel cycles.

Fast breeder reactors

MOX fuel enhances the efficiency of fast breeder reactors by recycling plutonium and uranium, significantly reducing nuclear waste compared to traditional uranium fuel.

Thermal neutron flux

MOX fuel exhibits a higher thermal neutron flux compared to traditional uranium fuel due to its mixed composition of plutonium and uranium oxides enhancing neutron multiplication.

Fissile material utilization

MOX fuel enhances fissile material utilization by recycling plutonium from spent nuclear fuel, increasing energy yield compared to traditional uranium-only fuel.

Radiotoxicity reduction

MOX fuel significantly reduces radiotoxicity by recycling plutonium and minor actinides, decreasing long-term nuclear waste hazard compared to traditional uranium fuel.

MOX fuel vs traditional fuel Infographic

njnir.com

njnir.com