Dry cask storage offers enhanced safety and long-term containment by isolating spent nuclear fuel in robust, airtight steel and concrete containers, minimizing radiation exposure and environmental risk. Wet storage involves submerging spent fuel rods in large pools of water, which provides effective cooling and shielding but requires continuous monitoring and active maintenance to prevent overheating or leaks. Choosing between dry cask and wet storage depends on factors such as storage duration, site conditions, and regulatory requirements for spent nuclear fuel management.

Table of Comparison

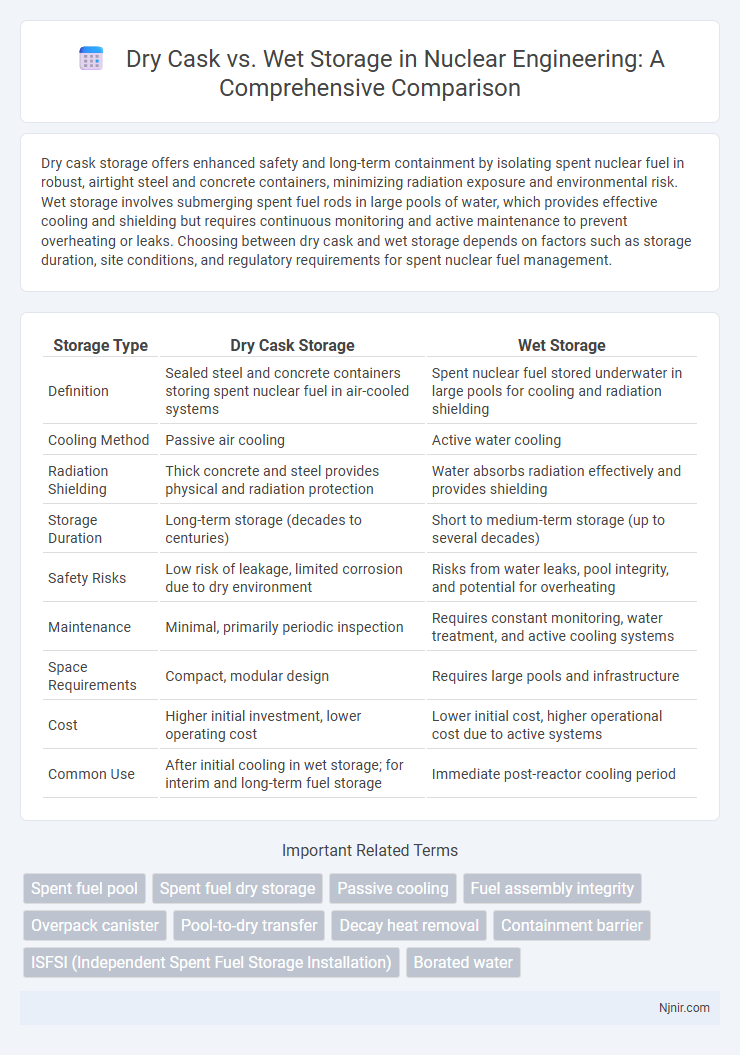

| Storage Type | Dry Cask Storage | Wet Storage |

|---|---|---|

| Definition | Sealed steel and concrete containers storing spent nuclear fuel in air-cooled systems | Spent nuclear fuel stored underwater in large pools for cooling and radiation shielding |

| Cooling Method | Passive air cooling | Active water cooling |

| Radiation Shielding | Thick concrete and steel provides physical and radiation protection | Water absorbs radiation effectively and provides shielding |

| Storage Duration | Long-term storage (decades to centuries) | Short to medium-term storage (up to several decades) |

| Safety Risks | Low risk of leakage, limited corrosion due to dry environment | Risks from water leaks, pool integrity, and potential for overheating |

| Maintenance | Minimal, primarily periodic inspection | Requires constant monitoring, water treatment, and active cooling systems |

| Space Requirements | Compact, modular design | Requires large pools and infrastructure |

| Cost | Higher initial investment, lower operating cost | Lower initial cost, higher operational cost due to active systems |

| Common Use | After initial cooling in wet storage; for interim and long-term fuel storage | Immediate post-reactor cooling period |

Overview of Spent Nuclear Fuel Storage Methods

Spent nuclear fuel storage methods include dry cask and wet storage, essential for safely managing radioactive materials post-reactor use. Wet storage involves submerging spent fuel in large pools of water, providing cooling and radiation shielding, widely adopted for initial storage immediately after removal from reactors. Dry cask storage encases spent fuel in sealed, inert gas-filled containers, offering long-term safety and portability when the fuel's heat generation decreases below a threshold.

Principles of Wet Storage for Spent Fuel

Wet storage for spent nuclear fuel relies on submerging fuel assemblies in deep pools of water that provide both radiation shielding and cooling capacity. The water circulation system maintains controlled temperatures to remove decay heat generated by the spent fuel, preventing overheating and maintaining fuel integrity. Continuous monitoring and chemistry control of the pool water are essential to minimize corrosion and ensure long-term safe storage of radioactive materials.

Fundamentals of Dry Cask Storage Technology

Dry cask storage technology involves securely sealing spent nuclear fuel in steel and concrete containers designed to provide radiation shielding and passive cooling through air circulation. Unlike wet storage, which relies on water pools to dissipate heat, dry casks use conductive and convective cooling methods, enhancing safety by reducing reliance on active systems. The robust design of dry casks ensures long-term containment of radioactivity and structural integrity under various environmental conditions.

Comparative Safety Considerations

Dry cask storage offers enhanced safety by isolating spent nuclear fuel in robust, air-cooled steel and concrete containers, minimizing the risk of leaks and environmental contamination compared to wet storage's reliance on water pools for cooling. Wet storage systems require continuous active cooling to prevent overheating, posing a higher risk during power outages or system failures, whereas dry casks provide passive safety features and greater resistance to natural disasters and accidents. Regulatory assessments and post-Fukushima safety upgrades emphasize dry cask storage as a more secure long-term solution due to its inherent structural integrity and reduced dependence on active cooling systems.

Storage Capacity and Scalability

Dry cask storage offers greater scalability and flexibility in storage capacity, allowing nuclear facilities to add storage units as needed without extensive infrastructure changes. Wet storage systems, typically spent fuel pools, have fixed capacity limited by pool size and require significant planning and expansion to accommodate additional fuel assemblies. The modular nature of dry casks enables efficient long-term storage expansions compared to the more space and resource-intensive wet storage solutions.

Operational and Maintenance Requirements

Dry cask storage requires minimal operational oversight and maintenance, primarily involving routine inspections for cask integrity, radiation shielding, and temperature monitoring systems. Wet storage systems demand continuous operational management, including water chemistry control, cooling system maintenance, and active corrosion prevention measures to ensure safe fuel containment. The lower complexity of dry cask storage results in reduced long-term maintenance costs compared to the intensive operational requirements of wet storage.

Long-Term Environmental Impact

Dry cask storage significantly reduces the risk of environmental contamination by isolating spent nuclear fuel in robust, corrosion-resistant steel and concrete containers, limiting radionuclide release over decades. Wet storage pools require continuous water circulation to cool fuel rods, posing risks of leaks, evaporation, and chemical corrosion that may lead to environmental contamination if maintenance fails. Over long-term periods, dry casks offer superior stability and minimal environmental impact compared to wet storage, which depends heavily on active monitoring and water management systems.

Regulatory and Licensing Challenges

Dry cask storage faces regulatory challenges related to rigorous safety assessments for long-term containment and radiation shielding, requiring detailed licensing processes from agencies such as the NRC. Wet storage involves complexities in maintaining water purity and structural integrity, demanding continuous regulatory oversight and periodic re-licensing to address potential corrosion and leakage risks. Both storage methods require comprehensive environmental impact evaluations and adherence to evolving nuclear regulatory standards to ensure operational safety and compliance.

Economic Analysis: Costs and Benefits

Dry cask storage involves higher upfront costs due to construction and material expenses but offers long-term economic benefits through reduced maintenance and operational requirements compared to wet storage. Wet storage requires continuous monitoring, cooling system operation, and infrastructure maintenance, resulting in increased operational costs over time. Economic analysis shows dry cask storage provides a cost-effective solution for long-term spent nuclear fuel management, balancing initial investment with lower ongoing expenses and enhanced safety.

Future Trends in Spent Fuel Management

Future trends in spent fuel management emphasize increased adoption of dry cask storage due to its enhanced safety, lower maintenance costs, and modular scalability compared to traditional wet storage pools. Innovations like improved cask materials and passive cooling systems are driving regulatory approvals worldwide, enabling longer-term on-site storage solutions. Advanced research explores integrating dry cask storage with deep geological repositories to optimize the nuclear fuel cycle and minimize environmental impact.

Spent fuel pool

Spent fuel pools provide underwater cooling and shielding for spent nuclear fuel, while dry cask storage offers above-ground, passive air-cooled containment for long-term spent fuel management.

Spent fuel dry storage

Spent fuel dry storage uses inert gas-filled steel or concrete casks for safer, long-term containment compared to wet storage pools, minimizing corrosion risks and environmental hazards.

Passive cooling

Dry cask storage relies on passive air cooling through natural convection, while wet storage depends on active water circulation to remove heat from spent nuclear fuel.

Fuel assembly integrity

Dry cask storage preserves fuel assembly integrity longer by minimizing corrosion and radiation damage compared to wet storage, which exposes assemblies to potential coolant-induced degradation.

Overpack canister

Overpack canisters enhance the safety of dry cask storage by providing an additional containment layer that prevents radiation leakage and improves structural integrity compared to wet storage methods.

Pool-to-dry transfer

Pool-to-dry transfer involves moving spent nuclear fuel from wet storage pools to dry cask storage systems, enhancing safety through reduced corrosion risks and improved radiation shielding.

Decay heat removal

Dry cask storage removes decay heat passively through natural convection and radiation, whereas wet storage relies on active cooling by circulating water to absorb and dissipate decay heat from spent nuclear fuel.

Containment barrier

Dry cask storage uses robust steel and concrete barriers to securely contain spent nuclear fuel, while wet storage relies on water pools as the primary containment and radiation shield.

ISFSI (Independent Spent Fuel Storage Installation)

ISFSI facilities primarily use dry cask storage for safer, long-term containment of spent nuclear fuel compared to wet storage pools.

Borated water

Borated water in wet storage systems effectively absorbs neutrons to enhance nuclear fuel safety, while dry cask storage relies on inert gas environments without borated water for long-term spent fuel containment.

dry cask vs wet storage Infographic

njnir.com

njnir.com