The containment building serves as the primary safety barrier, designed to prevent the release of radioactive materials into the environment during accidents. The reactor vessel houses the nuclear core and coolant, maintaining structural integrity under high temperatures and pressures. Unlike the reactor vessel, the containment building is a large, robust structure engineered to withstand external impacts and extreme internal conditions.

Table of Comparison

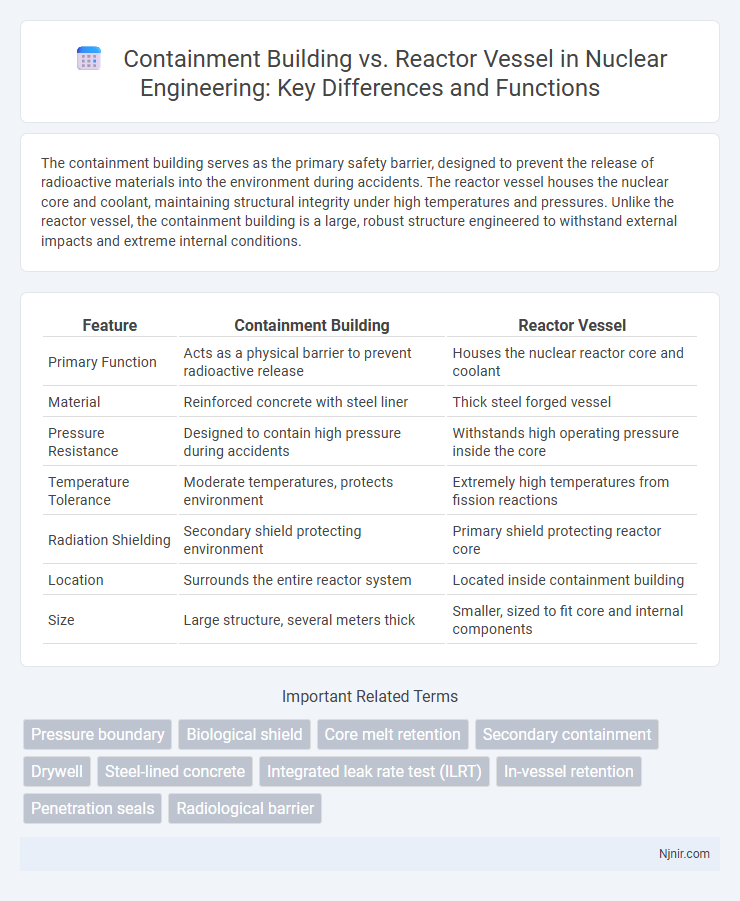

| Feature | Containment Building | Reactor Vessel |

|---|---|---|

| Primary Function | Acts as a physical barrier to prevent radioactive release | Houses the nuclear reactor core and coolant |

| Material | Reinforced concrete with steel liner | Thick steel forged vessel |

| Pressure Resistance | Designed to contain high pressure during accidents | Withstands high operating pressure inside the core |

| Temperature Tolerance | Moderate temperatures, protects environment | Extremely high temperatures from fission reactions |

| Radiation Shielding | Secondary shield protecting environment | Primary shield protecting reactor core |

| Location | Surrounds the entire reactor system | Located inside containment building |

| Size | Large structure, several meters thick | Smaller, sized to fit core and internal components |

Introduction to Containment Buildings and Reactor Vessels

Containment buildings are robust, airtight structures designed to enclose the nuclear reactor vessel and prevent the release of radioactive materials during accidents. Reactor vessels house the nuclear fuel assemblies where the fission reaction occurs and heat is generated for power production. Together, the containment building and reactor vessel form critical safety and operational components in a nuclear power plant's design.

Core Functions: Containment vs. Reactor Vessel

The containment building serves as a robust barrier designed to prevent the release of radioactive materials during normal operation and potential accidents, ensuring environmental and public safety. The reactor vessel houses the nuclear reactor core, facilitating the controlled nuclear fission process and maintaining critical operating conditions such as pressure and temperature. Together, the containment building and reactor vessel provide complementary safety functions by isolating radioactive materials and managing the core's physical and thermal stability.

Structural Design and Material Differences

Containment buildings are large, reinforced concrete structures designed to encase the entire nuclear reactor system and withstand extreme pressure, radiation, and potential external hazards, using thick steel liners and high-strength concrete for durability and leak prevention. Reactor vessels, by contrast, are made from specialized, corrosion-resistant steel alloys engineered to contain the nuclear fuel and coolant under high temperature and pressure conditions while maintaining structural integrity during fission reactions. The containment building focuses on overall plant safety and environmental protection, while the reactor vessel prioritizes precise thermal and mechanical performance within the reactor core.

Safety Roles in Nuclear Power Plants

The containment building serves as a robust barrier designed to prevent the release of radioactive materials into the environment during accidents by enclosing the reactor vessel and associated systems. The reactor vessel houses the nuclear fuel and controls the fission reaction, playing a critical role in maintaining reactor core integrity and temperature regulation. Together, these components ensure safety by mitigating radiation exposure risks and maintaining structural containment under normal and emergency conditions in nuclear power plants.

Pressure and Temperature Resistance Comparison

The containment building is engineered to withstand high-pressure scenarios during accidental releases, typically designed to tolerate pressures up to 50 psi (approximately 345 kPa) to prevent radioactive leaks. In contrast, the reactor vessel operates under extreme temperature and pressure conditions, sustaining internal pressures around 2200 psi (15 MPa) and temperatures exceeding 300degC during normal reactor operations. While the reactor vessel focuses on maintaining integrity under intense heat and pressure to contain nuclear reactions, the containment building primarily serves as a secondary barrier, designed to resist lower pressures but over a larger volume to ensure overall plant safety.

Radiation Shielding Capabilities

The containment building provides a robust barrier designed to prevent the release of radioactive materials into the environment, featuring thick reinforced concrete walls that effectively absorb radiation and protect surrounding areas. In contrast, the reactor vessel primarily functions to house the nuclear core and coolant, offering localized radiation shielding through its thick steel construction but not designed to contain radiation outside the reactor system. Together, these structures ensure multi-layered radiation protection by combining the reactor vessel's direct shielding with the containment building's comprehensive enclosure.

Maintenance and Inspection Practices

Containment buildings require regular structural integrity assessments to prevent radiation leaks, employing methods like visual inspections, ultrasonic testing, and leak rate measurements to maintain safety standards. Reactor vessels undergo detailed internal and external examinations, including ultrasonic testing, radiographic inspections, and thermal imaging, ensuring early detection of corrosion, cracks, or neutron embrittlement. Maintenance practices for containment buildings emphasize corrosion control and sealant inspections, while reactor vessel protocols focus on pressure boundary integrity and material degradation analysis to extend operational life.

Regulatory Requirements and Standards

Containment buildings must comply with strict regulatory requirements such as ASME NQA-1 and 10 CFR Part 50 Appendix A, ensuring structural integrity against extreme events like earthquakes, aircraft impacts, and severe accidents. Reactor vessels adhere to ASME Boiler and Pressure Vessel Code Section III, emphasizing material toughness, fracture toughness, and fatigue resistance to withstand high temperature, pressure, and neutron irradiation over operational life. Regulatory standards mandate rigorous quality assurance, non-destructive examination, and periodic in-service inspections for both components to guarantee safety and extend service life.

Historical Case Studies and Lessons Learned

Historical case studies, such as the Three Mile Island accident in 1979, highlight the critical role of containment buildings in preventing radioactive release despite reactor vessel damage. Containment buildings are robust structures designed to enclose the reactor vessel, providing an additional safety barrier against nuclear fission byproducts during malfunctions. Lessons learned emphasize enhancing containment integrity and emergency response protocols to mitigate risks associated with reactor vessel breaches.

Future Trends in Containment and Reactor Vessel Design

Future trends in containment building and reactor vessel design emphasize enhanced safety features and extended operational lifespans through advanced materials like high-performance steel alloys and composite structures. Innovations include modular containment systems and passive safety mechanisms that improve resilience against extreme events such as earthquakes and severe accidents. Integration of digital monitoring technologies and predictive maintenance tools enables real-time performance assessment, driving improvements in nuclear plant efficiency and risk management.

Pressure boundary

The containment building serves as the ultimate pressure boundary designed to prevent the release of radioactive materials, while the reactor vessel is the primary pressure boundary containing the reactor core and coolant under high pressure.

Biological shield

The biological shield in containment buildings primarily protects personnel from radiation by absorbing neutron and gamma rays, whereas the reactor vessel provides a physical barrier containing the nuclear fuel and coolant but offers limited radiation shielding.

Core melt retention

Containment buildings are designed to prevent the release of radioactive materials during a core melt, while reactor vessels focus on retaining the core melt to avoid breaching containment integrity.

Secondary containment

The secondary containment in a nuclear power plant surrounds the reactor vessel and primary containment to prevent radioactive release, providing an additional barrier against environmental contamination.

Drywell

The drywell in a containment building surrounds the reactor vessel to provide a pressure-resistant barrier that confines steam and radioactive materials during a reactor accident.

Steel-lined concrete

Steel-lined concrete containment buildings provide enhanced radiation shielding and structural integrity compared to reactor vessels, which are primarily designed to house the nuclear core and coolant under high pressure.

Integrated leak rate test (ILRT)

The Integrated Leak Rate Test (ILRT) primarily assesses the containment building's overall airtightness, while the reactor vessel itself undergoes separate pressure and integrity tests to ensure reactor coolant system safety.

In-vessel retention

In-vessel retention enhances nuclear safety by cooling the reactor vessel from within to prevent core meltdown, while the containment building provides an external barrier to contain radioactive materials in case of vessel failure.

Penetration seals

Containment building penetration seals provide robust airtight barriers to prevent radioactive leakage, whereas reactor vessel penetration seals ensure secure, pressure-resistant joints for control rod and instrumentation access within the vessel.

Radiological barrier

The containment building serves as the primary radiological barrier by enclosing the reactor vessel and preventing the release of radioactive materials into the environment.

containment building vs reactor vessel Infographic

njnir.com

njnir.com