Passive safety systems in nuclear engineering rely on natural physical principles such as gravity, natural circulation, and convection to maintain reactor safety without human intervention or mechanical failure risks. Active safety systems depend on engineered components like pumps, valves, and electronic controls to manage and mitigate potential hazards, requiring power sources and operator actions. Passive safety designs enhance reliability and reduce complexity, improving overall reactor safety by minimizing dependency on external inputs.

Table of Comparison

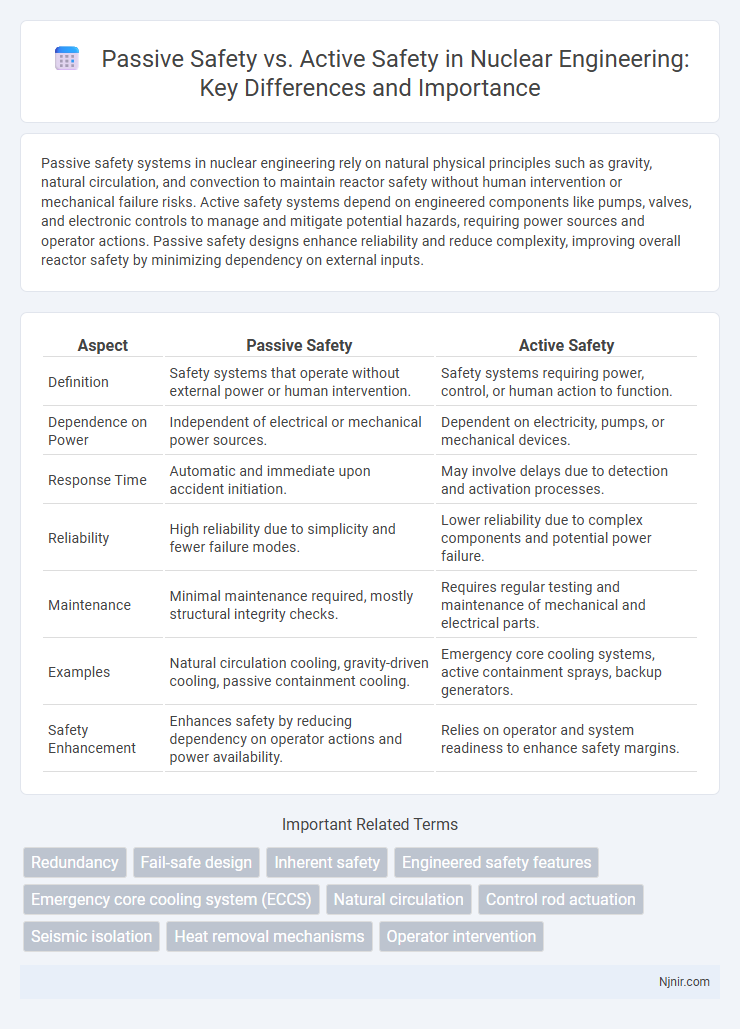

| Aspect | Passive Safety | Active Safety |

|---|---|---|

| Definition | Safety systems that operate without external power or human intervention. | Safety systems requiring power, control, or human action to function. |

| Dependence on Power | Independent of electrical or mechanical power sources. | Dependent on electricity, pumps, or mechanical devices. |

| Response Time | Automatic and immediate upon accident initiation. | May involve delays due to detection and activation processes. |

| Reliability | High reliability due to simplicity and fewer failure modes. | Lower reliability due to complex components and potential power failure. |

| Maintenance | Minimal maintenance required, mostly structural integrity checks. | Requires regular testing and maintenance of mechanical and electrical parts. |

| Examples | Natural circulation cooling, gravity-driven cooling, passive containment cooling. | Emergency core cooling systems, active containment sprays, backup generators. |

| Safety Enhancement | Enhances safety by reducing dependency on operator actions and power availability. | Relies on operator and system readiness to enhance safety margins. |

Introduction to Passive and Active Safety in Nuclear Engineering

Passive safety systems in nuclear engineering rely on natural physical principles such as gravity, natural circulation, and inherent material properties to maintain reactor safety without external power or human intervention. Active safety systems depend on mechanical and electrical components like pumps, valves, and control rods that require power, monitoring, and operator action to respond to abnormal conditions. Understanding the distinction between these systems is crucial for designing reactors that ensure reliable containment of radiation and safe shutdown during emergencies.

Fundamental Principles of Passive Safety Systems

Passive safety systems rely on structural design and built-in features to protect occupants during a crash without requiring external activation. Fundamental principles include energy absorption through crumple zones, reinforced passenger compartments, and the use of airbags and seat belts to reduce injury risk. These systems operate automatically and enhance occupant protection by minimizing the forces experienced in collisions.

Key Features of Active Safety Mechanisms

Active safety mechanisms include technologies such as anti-lock braking systems (ABS), electronic stability control (ESC), and adaptive cruise control, which actively prevent accidents by enhancing vehicle control and driver awareness. These systems rely on sensors and real-time data processing to detect potential hazards and automatically adjust braking, steering, or acceleration. Emphasizing proactive collision avoidance, active safety features significantly reduce the likelihood of accidents compared to passive safety systems that only protect occupants during a crash.

Historical Development of Safety Approaches in Nuclear Plants

The historical development of safety approaches in nuclear plants shifted from primarily passive safety systems, such as containment structures designed to prevent radiation release during accidents, toward integrating active safety systems that rely on sensors, control mechanisms, and automated responses to detect and mitigate operational anomalies. Early reactors, like the Shippingport Atomic Power Station, emphasized robust passive barriers, while advancements in reactor technology introduced active components, exemplified by the safety systems in Generation III+ reactors like the AP1000, which combine passive cooling with active monitoring for enhanced risk management. Regulatory frameworks established after major incidents, such as the Three Mile Island and Fukushima disasters, accelerated the incorporation of active safety features alongside passive systems to improve overall plant resilience and safety performance.

Comparison of Reliability: Passive vs. Active Safety

Passive safety systems, such as airbags and seat belts, provide reliable protection by minimizing injury during an accident without requiring user intervention. Active safety technologies, including automatic emergency braking and lane-keeping assist, depend on sensors and software, which can occasionally malfunction or be less effective in adverse conditions. The reliability of passive safety remains consistent over time, while active safety's performance is highly contingent on technology accuracy and maintenance.

Case Studies: Notable Nuclear Incidents and Safety Responses

Case studies of notable nuclear incidents, such as the Chernobyl disaster and Fukushima Daiichi accident, highlight the critical roles of both passive and active safety systems in mitigating catastrophic outcomes. Passive safety measures, including containment structures and natural circulation cooling, function without external power or human intervention, providing fail-safe protection during system failures. Active safety systems rely on sensors, alarms, and automated controls to detect anomalies and initiate corrective actions, but case reviews emphasize the necessity of integrating robust passive features to ensure resilience when active components fail.

Economic Implications of Passive and Active Safety Systems

Passive safety systems, such as airbags and crumple zones, often involve one-time manufacturing costs but can reduce medical expenses by minimizing injury severity during accidents. Active safety technologies, including automatic emergency braking and lane-keeping assist, may require higher initial investments and ongoing software updates but contribute to long-term economic savings by preventing collisions and lowering insurance premiums. Balancing the upfront costs and potential financial benefits is crucial for automakers and policymakers aiming to optimize vehicle safety while managing overall economic impact.

Regulatory Perspectives and Standards for Safety Approaches

Regulatory frameworks such as the United Nations Economic Commission for Europe (UNECE) set stringent standards for both passive and active vehicle safety, mandating features like airbags, crumple zones, and advanced driver-assistance systems (ADAS). Active safety standards prioritize technologies that prevent accidents, including automatic emergency braking (AEB) and lane-keeping assist (LKA), while passive safety regulations focus on minimizing injury during collisions through robust structural integrity and restraint systems. Compliance with regulatory requirements like FMVSS in the United States and Euro NCAP protocols in Europe ensures a balanced integration of both safety approaches to enhance overall road safety.

Technological Innovations in Reactor Safety Designs

Technological innovations in reactor safety designs have significantly enhanced both passive and active safety systems, with passive safety relying on natural physical principles such as gravity, convection, and natural circulation to maintain reactor stability without external power or human intervention. Active safety systems incorporate advanced sensors, automated control systems, and real-time monitoring technologies to detect anomalies and initiate safety measures, ensuring rapid response to potential incidents. Integration of digital instrumentation and artificial intelligence further optimizes the coordination between passive and active safety mechanisms, improving overall reactor resilience and accident mitigation.

Future Trends: Integrating Passive and Active Safety for Next-Generation Reactors

Next-generation reactors prioritize the integration of passive and active safety systems to enhance overall reliability and risk mitigation. Advanced designs incorporate passive cooling mechanisms alongside automated active controls that respond dynamically to operational conditions, reducing dependency on external power sources. This holistic safety approach leverages real-time data analytics and redundant fail-safe features to ensure resilient performance under emergency scenarios.

Redundancy

Passive safety systems rely on structural design and materials to protect occupants during a crash, while active safety systems use redundant sensors and controls to prevent accidents before they occur.

Fail-safe design

Fail-safe design in passive safety ensures vehicle components maintain protection during system failures, while active safety relies on real-time interventions to prevent accidents.

Inherent safety

Inherent safety in passive safety systems relies on built-in design features that automatically protect users without requiring external intervention, contrasting with active safety systems that depend on sensors and user responses.

Engineered safety features

Engineered passive safety features, such as crumple zones and airbags, complement active safety systems like automatic emergency braking to reduce injury severity in vehicle collisions.

Emergency core cooling system (ECCS)

The Emergency Core Cooling System (ECCS) enhances passive safety by providing automatic, reliable coolant injection during loss-of-coolant accidents, contrasting with active safety systems that require operator intervention or powered components.

Natural circulation

Natural circulation enhances passive safety by enabling coolant flow without pumps, reducing reliance on active safety systems during emergency cooling.

Control rod actuation

Control rod actuation is a critical passive safety feature in nuclear reactors that automatically inserts control rods to shut down the reactor during abnormal conditions, contrasting with active safety systems that require external power or operator intervention.

Seismic isolation

Seismic isolation enhances passive safety by decoupling buildings from ground motion, reducing structural damage without requiring active mechanical intervention.

Heat removal mechanisms

Passive safety mechanisms rely on natural convection and radiation for heat removal, while active safety systems use mechanical components like pumps and fans to enhance heat dissipation.

Operator intervention

Passive safety systems protect occupants without requiring operator intervention, whereas active safety systems rely on real-time operator interaction or automated responses to prevent accidents.

passive safety vs active safety Infographic

njnir.com

njnir.com