Dry storage systems for spent nuclear fuel utilize robust, sealed containers that provide passive cooling and radiation shielding, minimizing corrosion risks compared to wet storage pools. Wet storage involves submerging fuel assemblies in pools of water, which offers effective heat removal and radiation protection but requires continuous maintenance and monitoring to prevent leaks and degradation. Advances in dry storage technology enhance long-term safety and cost-efficiency by reducing dependency on active cooling systems and complex infrastructure.

Table of Comparison

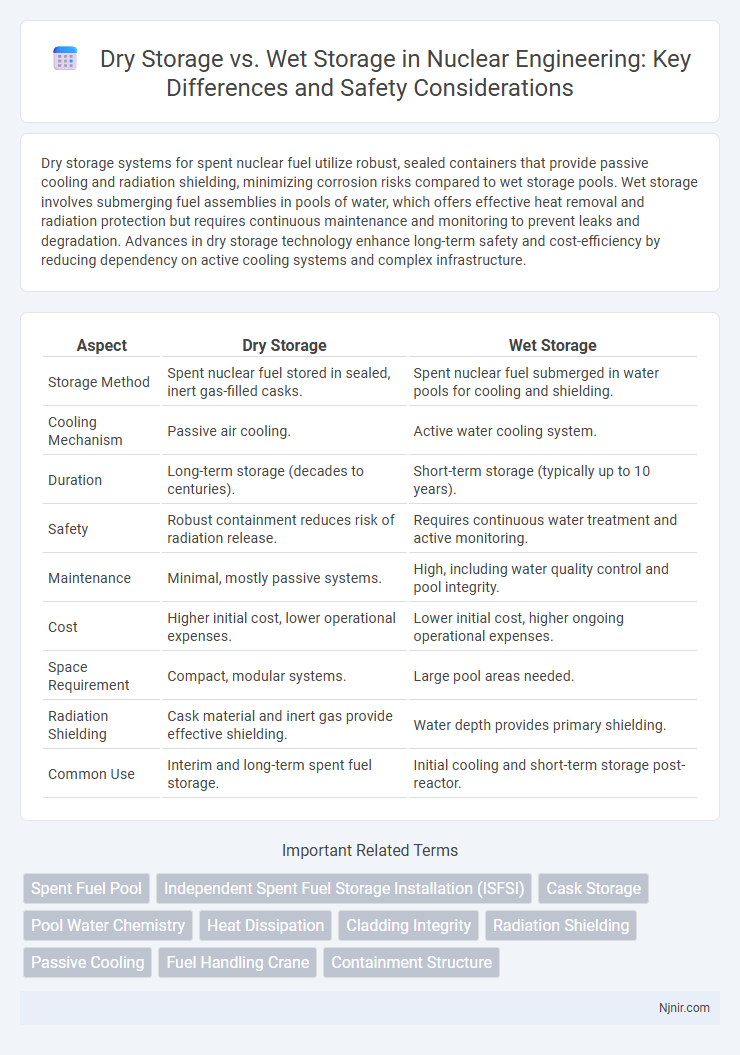

| Aspect | Dry Storage | Wet Storage |

|---|---|---|

| Storage Method | Spent nuclear fuel stored in sealed, inert gas-filled casks. | Spent nuclear fuel submerged in water pools for cooling and shielding. |

| Cooling Mechanism | Passive air cooling. | Active water cooling system. |

| Duration | Long-term storage (decades to centuries). | Short-term storage (typically up to 10 years). |

| Safety | Robust containment reduces risk of radiation release. | Requires continuous water treatment and active monitoring. |

| Maintenance | Minimal, mostly passive systems. | High, including water quality control and pool integrity. |

| Cost | Higher initial cost, lower operational expenses. | Lower initial cost, higher ongoing operational expenses. |

| Space Requirement | Compact, modular systems. | Large pool areas needed. |

| Radiation Shielding | Cask material and inert gas provide effective shielding. | Water depth provides primary shielding. |

| Common Use | Interim and long-term spent fuel storage. | Initial cooling and short-term storage post-reactor. |

Introduction to Spent Nuclear Fuel Storage

Spent nuclear fuel requires secure storage solutions to prevent radiation release and environmental contamination. Dry storage involves sealing fuel rods in robust steel or concrete casks, offering enhanced safety and long-term stability compared to wet storage, which pools fuel assemblies in water to provide cooling and radiation shielding. Selection between dry and wet storage depends on factors like fuel cooling time, facility capacity, and regulatory standards for radiation protection.

Overview of Wet Storage Methods

Wet storage methods involve submerging spent nuclear fuel in specially designed pools filled with water to provide efficient cooling and radiation shielding. These pools, typically constructed with reinforced concrete and stainless steel liners, maintain controlled temperatures and water chemistry to prevent corrosion and ensure safety. Wet storage remains the preferred choice for short to medium-term management of radioactive materials due to its proven effectiveness in heat dissipation and radiation protection.

Overview of Dry Storage Methods

Dry storage methods for spent nuclear fuel primarily involve sealed metal or concrete casks that provide a robust barrier against radiation and environmental factors. These casks are engineered to dissipate heat generated by the spent fuel through passive air cooling systems, eliminating the need for active cooling mechanisms. Dry storage offers long-term, secure containment with reduced risk of corrosion compared to wet storage pools, making it a preferred solution for interim storage prior to final disposal or reprocessing.

Safety Considerations: Wet vs. Dry Storage

Wet storage involves submerging spent nuclear fuel in water pools that provide effective radiation shielding and cooling, reducing the risk of overheating and radiation exposure. Dry storage uses robust, airtight casks made from concrete and steel, ensuring safe containment and passive cooling, minimizing the risk of environmental contamination. Both methods prioritize safety, but wet storage relies on active water circulation systems, while dry storage emphasizes passive integrity and long-term stability under varied conditions.

Cost Comparison: Dry Storage vs. Wet Storage

Dry storage systems generally incur higher initial costs due to the need for specialized casks and infrastructure, but they offer lower long-term operational expenses compared to wet storage. Wet storage requires continuous maintenance of pools with water treatment, filtration, and cooling systems, increasing ongoing energy and labor costs. Over extended periods, dry storage proves more cost-effective by minimizing risks related to water leakage and corrosion.

Environmental Impact Analysis

Dry storage of spent nuclear fuel significantly reduces the risk of water contamination and long-term environmental pollution compared to wet storage, which relies on large pools of water that can leak or evaporate toxic radionuclides. The minimal water usage and reduced potential for radioactive leakage in dry storage make it a more sustainable and environmentally secure option for long-term nuclear waste management. Lifecycle assessments indicate that dry storage systems have lower greenhouse gas emissions and ecological footprints due to less maintenance and reduced risk of accidental releases.

Long-Term Storage and Waste Management

Dry storage offers enhanced safety and environmental protection for long-term storage of spent nuclear fuel by utilizing robust, sealed metal or concrete casks that prevent radiation leaks and corrosion. Wet storage, involving pools of water that cool and shield spent fuel, is more suitable for short to medium-term storage but presents increased risks over long periods due to potential water contamination and structural degradation. Effective waste management strategies prioritize dry storage to minimize environmental impact and ensure secure containment over decades to centuries.

Regulatory Framework and Compliance

Dry storage systems for spent nuclear fuel typically comply with strict regulatory frameworks established by entities such as the U.S. Nuclear Regulatory Commission (NRC) and the International Atomic Energy Agency (IAEA), ensuring robust containment, radiation shielding, and thermal performance standards. Wet storage facilities are subject to comprehensive regulations focusing on water chemistry control, structural integrity of pools, and continuous monitoring to prevent corrosion and radiological hazards in accordance with NRC's 10 CFR Part 50 and IAEA safety standards. Regulatory compliance for both storage methods mandates periodic safety assessments, license renewals, and adherence to emergency preparedness protocols to mitigate radiological risks over extended storage durations.

Technological Advancements in Storage Systems

Technological advancements in dry storage systems have enhanced safety through improved inert gas environments and modular designs that facilitate better heat dissipation and structural integrity. Wet storage technology now incorporates advanced filtration and cooling systems using robotics for precise fuel handling, significantly reducing radiation exposure risks. Innovations in sensor integration and real-time monitoring optimize both dry and wet storage, ensuring efficient management and extended storage durations for spent nuclear fuel.

Future Trends in Nuclear Fuel Storage

Future trends in nuclear fuel storage emphasize advancements in dry storage technologies due to their enhanced safety, scalability, and cost-efficiency compared to traditional wet storage methods. Innovations such as passive cooling systems and improved cask materials are increasing the long-term durability and radiation shielding capabilities of dry storage. Research into hybrid storage solutions and integration with advanced monitoring technologies is also paving the way for more secure and environmentally sustainable nuclear fuel management.

Spent Fuel Pool

Spent Fuel Pools provide wet storage that cools and shields nuclear waste, while dry storage offers sealed, inert environments for long-term containment after initial cooling in the pool.

Independent Spent Fuel Storage Installation (ISFSI)

Independent Spent Fuel Storage Installations (ISFSIs) primarily utilize dry storage systems, which securely contain spent nuclear fuel in robust, air-cooled casks offering enhanced safety and reduced environmental risks compared to traditional wet storage pools.

Cask Storage

Cask storage offers a safer, more cost-effective, and environmentally stable dry storage solution for spent nuclear fuel compared to wet storage pools.

Pool Water Chemistry

Pool water chemistry in wet storage requires continuous monitoring of pH, chlorine, and conductivity to prevent corrosion and biological growth, whereas dry storage eliminates the need for chemical treatment but demands strict humidity and temperature control to maintain material integrity.

Heat Dissipation

Dry storage systems provide superior heat dissipation compared to wet storage by utilizing air circulation and engineered ventilation to efficiently remove residual decay heat.

Cladding Integrity

Dry storage maintains superior cladding integrity by minimizing corrosion risks compared to wet storage environments.

Radiation Shielding

Dry storage provides superior radiation shielding by utilizing thick concrete and steel casks that effectively reduce radiation exposure compared to wet storage, which relies on water as a radiation barrier but requires constant maintenance to prevent corrosion and ensure safety.

Passive Cooling

Dry storage employs passive cooling through natural air circulation around fuel casks, whereas wet storage relies on active water circulation to dissipate heat from spent nuclear fuel.

Fuel Handling Crane

Fuel Handling Cranes in dry storage facilities offer enhanced safety and maintenance efficiency by eliminating water exposure, unlike wet storage systems where cranes operate submerged, increasing corrosion risks and requiring specialized waterproof equipment.

Containment Structure

Dry storage containment structures utilize robust, airtight casks made of steel and concrete to isolate spent nuclear fuel, whereas wet storage relies on large pools with reinforced concrete walls and water as a radiation shield.

dry storage vs wet storage Infographic

njnir.com

njnir.com