VVER reactors utilize light water as both coolant and moderator, featuring a pressurized water design that ensures high thermal efficiency and robust safety systems. CANDU reactors employ heavy water moderation and coolant, enabling the use of natural uranium fuel without enrichment, which reduces fuel processing costs. The differing coolant and moderator selections lead to distinct operational advantages, with VVERs emphasizing standardization and fuel flexibility, while CANDUs prioritize fuel cycle economics and on-line refueling capability.

Table of Comparison

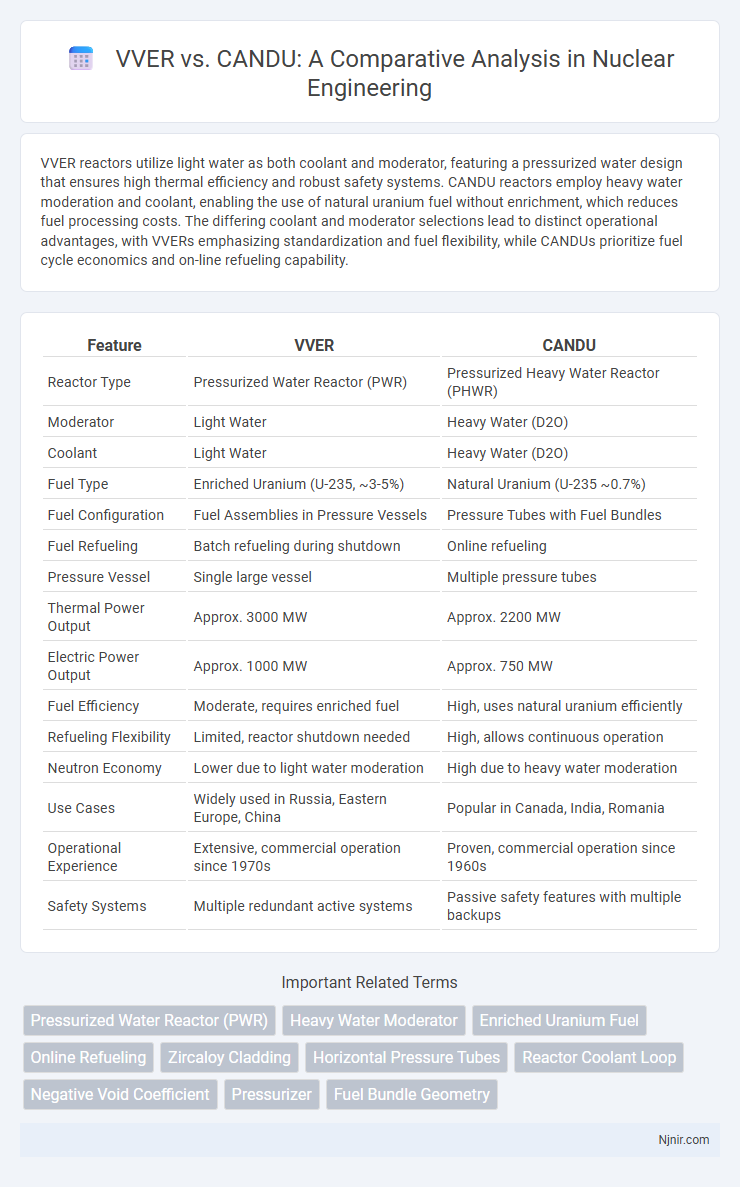

| Feature | VVER | CANDU |

|---|---|---|

| Reactor Type | Pressurized Water Reactor (PWR) | Pressurized Heavy Water Reactor (PHWR) |

| Moderator | Light Water | Heavy Water (D2O) |

| Coolant | Light Water | Heavy Water (D2O) |

| Fuel Type | Enriched Uranium (U-235, ~3-5%) | Natural Uranium (U-235 ~0.7%) |

| Fuel Configuration | Fuel Assemblies in Pressure Vessels | Pressure Tubes with Fuel Bundles |

| Fuel Refueling | Batch refueling during shutdown | Online refueling |

| Pressure Vessel | Single large vessel | Multiple pressure tubes |

| Thermal Power Output | Approx. 3000 MW | Approx. 2200 MW |

| Electric Power Output | Approx. 1000 MW | Approx. 750 MW |

| Fuel Efficiency | Moderate, requires enriched fuel | High, uses natural uranium efficiently |

| Refueling Flexibility | Limited, reactor shutdown needed | High, allows continuous operation |

| Neutron Economy | Lower due to light water moderation | High due to heavy water moderation |

| Use Cases | Widely used in Russia, Eastern Europe, China | Popular in Canada, India, Romania |

| Operational Experience | Extensive, commercial operation since 1970s | Proven, commercial operation since 1960s |

| Safety Systems | Multiple redundant active systems | Passive safety features with multiple backups |

Introduction to VVER and CANDU Reactor Technologies

VVER (Water-Water Energetic Reactor) is a Russian-designed pressurized water reactor (PWR) known for its robust safety features and advanced cooling systems using light water as both coolant and moderator. CANDU (CANada Deuterium Uranium) is a Canadian heavy water reactor that utilizes natural uranium fuel and heavy water as a moderator, enabling on-line refueling and enhanced neutron economy. Both technologies represent significant advancements in nuclear reactor design with distinct approaches to fuel usage, moderator selection, and operational flexibility.

Core Design Differences: VVER vs CANDU

VVER reactors utilize pressurized water in a pressurized water reactor (PWR) design with enriched uranium fuel contained in zirconium alloy fuel rods arranged in a hexagonal core. CANDU reactors employ heavy water as both moderator and coolant, allowing the use of natural uranium fuel in horizontal pressure tubes rather than a large pressure vessel. The VVER core design emphasizes high-pressure coolant loops and integrated steam generators, whereas the CANDU design is modular, enabling on-power refueling and improved neutron economy due to heavy water moderation.

Fuel Types and Utilization: A Comparative Analysis

VVER reactors utilize low-enriched uranium dioxide (LEU) fuel, typically enriched to about 3-5% U-235, offering a higher energy density and longer fuel cycles compared to natural uranium. CANDU reactors operate on natural uranium fuel with heavy water moderation, enabling on-line refueling and flexibility to use alternative fuels such as thorium or reprocessed uranium. The VVER's enriched fuel allows for compact core designs, whereas CANDU's natural uranium usage and refueling capability enhance fuel utilization efficiency and reduce fuel fabrication costs.

Heavy Water Versus Light Water Moderation

Heavy water moderation in CANDU reactors allows for superior neutron economy by using deuterium oxide, which has a much lower neutron absorption cross-section than the light water used in VVER reactors. This enables CANDU reactors to utilize natural uranium fuel without enrichment, improving fuel efficiency and resource utilization. In contrast, VVER reactors rely on light water as both coolant and moderator, requiring enriched uranium fuel and resulting in higher neutron losses but simpler reactor design.

Safety Features and Passive Safety Systems

VVER reactors incorporate multiple redundant safety systems, including diverse active and passive components such as passive heat removal and core catchers that enhance accident mitigation. CANDU reactors leverage heavy water moderation and have distinct passive safety features like a large heat sink from the moderator tank and on-power refueling that reduces operational risk. Both designs prioritize containment integrity, but VVER emphasizes layered safety barriers, while CANDU excels in inherent safety through low-pressure moderator systems and separate cooling circuits.

Operational Flexibility and Load-Following Capabilities

The VVER reactor design offers enhanced operational flexibility with robust load-following capabilities that adjust power output efficiently according to grid demand, making it suitable for variable energy integration. In contrast, the CANDU reactor excels in maintaining steady-state operations but features more limited load-following performance due to its heavy-water moderated system and on-line refueling process. VVER's ability to dynamically modulate power centralizes its application in grids with fluctuating demand, while CANDU reactors prioritize consistent output and fuel flexibility.

Spent Fuel Management and Waste Disposal

VVER reactors generate spent fuel with higher enrichment levels, requiring long-term cooling and geological disposal strategies tailored to their relatively smaller volume but higher radioactivity. CANDU reactors use natural uranium, producing larger volumes of spent fuel with lower enrichment and differing isotopic composition, facilitating options like on-site dry storage or reprocessing for recycling fuel. Waste disposal for both designs emphasizes robust containment systems and monitoring to address their distinct spent fuel characteristics and minimize environmental impact.

Efficiency and Performance Metrics

VVER reactors achieve thermal efficiencies around 33-36% due to their pressurized water design, optimizing heat transfer through their closed-loop coolant system. CANDU reactors typically exhibit thermal efficiencies near 30-34%, influenced by their heavy water moderation and ability to use natural uranium, which affects neutron economy and fuel burnup. Performance metrics such as capacity factor highlight VVERs often reach over 90%, while CANDUs average around 85-90%, reflecting differences in refueling flexibility and operational maintenance schedules.

Global Deployment and Historical Development

VVER reactors, primarily developed in Russia, have seen extensive deployment across Eastern Europe, Asia, and parts of the Middle East, with over 30 units operational since their introduction in the 1960s. CANDU reactors, originating in Canada during the 1950s, are notable for their use in Canada, China, India, and South Korea, with more than 50 reactors built globally, valued for their natural uranium fuel capability. Both reactor types have evolved through decades of technological advancements, influencing global nuclear energy strategies by offering distinct benefits in fuel flexibility and reactor design robustness.

Future Prospects: Innovations and Upgrades

VVER reactors are advancing with enhanced fuel designs and digital control systems, aiming to improve safety, efficiency, and waste management. CANDU technology is evolving through the development of advanced fuel cycles, including thorium use and online refueling upgrades that boost operational flexibility. Both designs emphasize modular construction and integration of passive safety features to meet future energy demands and environmental standards.

Pressurized Water Reactor (PWR)

VVER, a Russian-designed Pressurized Water Reactor (PWR), differs from the Canadian CANDU reactor by using enriched uranium fuel and light water coolant under high pressure, whereas CANDU employs natural uranium fuel and heavy water moderator for efficient neutron economy.

Heavy Water Moderator

The VVER reactor uses light water as a moderator and coolant, whereas the CANDU reactor employs heavy water as a moderator, enabling it to utilize natural uranium fuel efficiently.

Enriched Uranium Fuel

VVER reactors use uranium fuel enriched to 3-5% U-235, while CANDU reactors primarily utilize natural uranium with 0.7% U-235, enabling CANDU's on-line refueling and lower fuel enrichment requirements.

Online Refueling

CANDU reactors enable efficient online refueling without shutdowns, while VVER reactors require shutdowns for refueling, impacting operational uptime.

Zircaloy Cladding

VVER reactors use zirconium alloy cladding similar to Zircaloy for fuel rods, offering high corrosion resistance and neutron economy, while CANDU reactors predominantly utilize Zircaloy-4 cladding to withstand high-pressure heavy water coolant and enable efficient neutron moderation.

Horizontal Pressure Tubes

VVER reactors utilize vertical pressure vessels, whereas CANDU reactors feature horizontal pressure tubes enabling on-power refueling and enhanced fuel management flexibility.

Reactor Coolant Loop

VVER reactors use a pressurized water coolant loop with integrated steam generators, while CANDU reactors employ heavy water moderator and coolant in a two-loop system with separate high-pressure and low-pressure circuits.

Negative Void Coefficient

The VVER reactor features a negative void coefficient enhancing safety by reducing reactivity during coolant loss, whereas the CANDU reactor's void coefficient is positive, posing greater risks of power surges under similar conditions.

Pressurizer

The VVER reactor uses a pressurizer to maintain system pressure and prevent coolant boiling, whereas the CANDU reactor relies on heavy water coolant under high pressure without a traditional pressurizer component.

Fuel Bundle Geometry

VVER reactors use hexagonal fuel assemblies with tightly packed fuel rods, while CANDU reactors employ cylindrical fuel bundles consisting of multiple thin zircaloy pressure tubes arranged in a circular pattern.

VVER vs CANDU Infographic

njnir.com

njnir.com